Low-acid-value polyester resin for ultralow-temperature curing powder coating and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of high acid value, low activity of powder coatings, high preparation costs, etc., to overcome coating defects and reduce formulation costs , Accelerate the effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

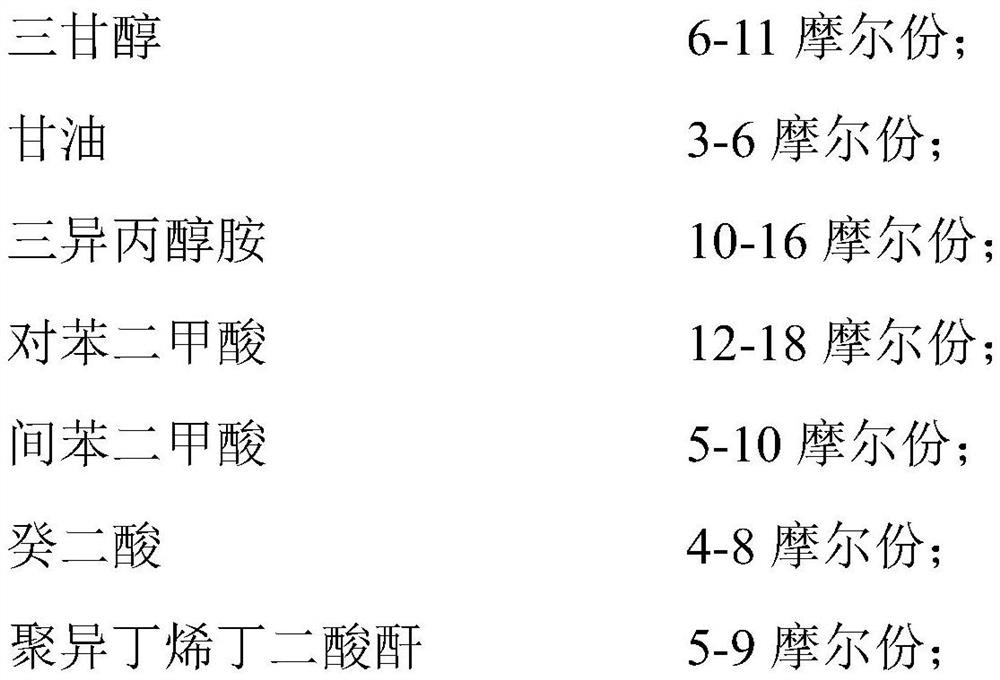

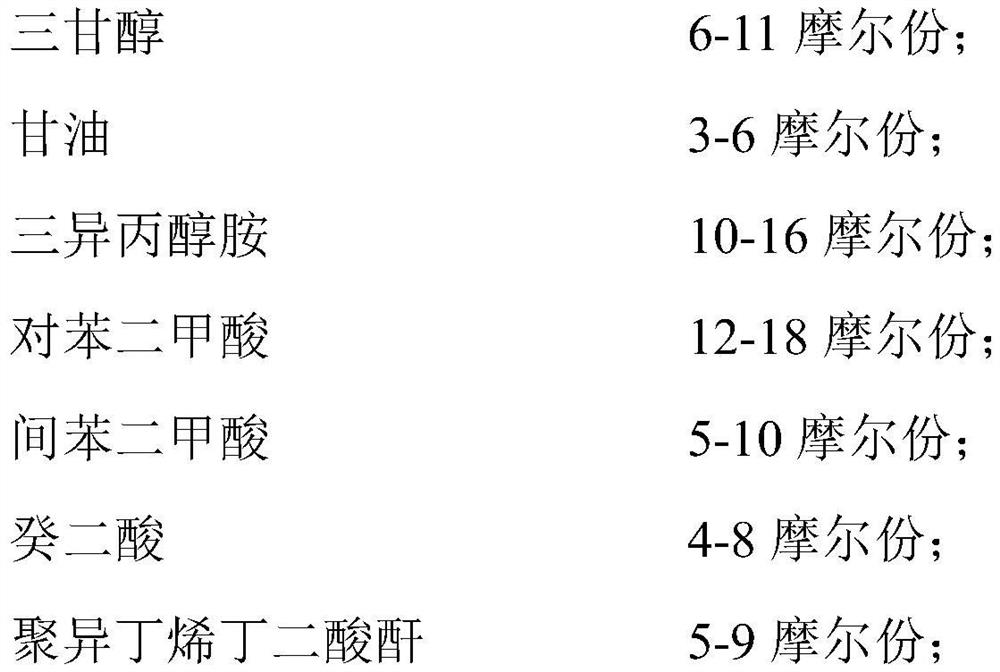

Method used

Image

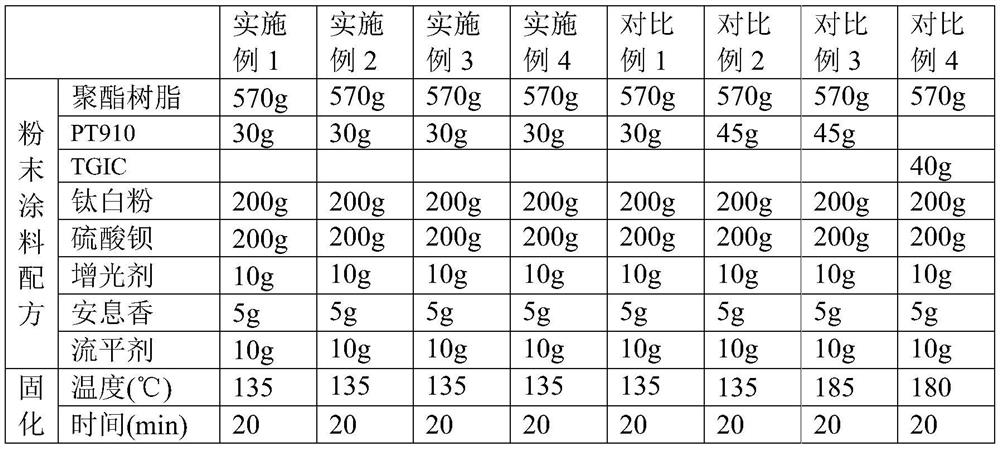

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a low-acid value polyester resin for ultra-low temperature curing powder coatings, which also includes the following steps:

[0035] (1) Add 10 molar parts of triethylene glycol and 4 molar parts of glycerin into the reaction kettle, and stir and mix evenly below 120°C; then add 13 molar parts of terephthalic acid in an amount of 0.12 % of the catalyst monobutyltin oxide, under the protection of nitrogen, the temperature is raised to 184°C at a heating rate of 17°C / h and kept warm for reaction;

[0036] (2) When the acid value of the reactants in the system is reduced to 61mgKOH / g, 5 molar parts of sebacic acid and 15 molar parts of triisopropanolamine are added at the same time, and the temperature is raised to 232 °C at a heating rate of 7 °C / h to continue Insulation for polymerization;

[0037] (3) When the acid value of the reactants in the system is reduced to 21mgKOH / g, add 9 molar parts of isophthalic acid, and con...

Embodiment 2

[0043] This embodiment provides a method for preparing a low-acid value polyester resin for ultra-low temperature curing powder coatings, which also includes the following steps:

[0044] (1) Add 7 molar parts of triethylene glycol and 5 molar parts of glycerin into the reaction kettle, and stir and mix evenly below 120°C; then add 15 molar parts of terephthalic acid in an amount of 0.18% of the total molar weight of raw materials % of the catalyst monobutyltin oxide, under the protection of nitrogen, the temperature is raised to 182°C at a heating rate of 16°C / h and kept for reaction;

[0045] (2) When the acid value of the reactants in the system is reduced to 63mgKOH / g, add 6 moles of sebacic acid and 14 moles of triisopropanolamine at the same time, and heat up to 234°C at a rate of 8°C / h to continue Insulation for polymerization;

[0046] (3) When the acid value of the system reactant is reduced to 22 mgKOH / g, add 8 molar parts of isophthalic acid, and continue to carry ...

Embodiment 3

[0052] This embodiment provides a method for preparing a low-acid value polyester resin for ultra-low temperature curing powder coatings, which also includes the following steps:

[0053] (1) Add 9 molar parts of triethylene glycol and 3 molar parts of glycerin into the reaction kettle, and stir and mix evenly below 120°C; then add 17 molar parts of terephthalic acid in an amount of 0.2 % of the catalyst monobutyltin oxide, under the protection of nitrogen, the temperature is raised to 182°C at a heating rate of 18°C / h and kept for reaction;

[0054] (2) When the acid value of the reactants in the system is reduced to 64mgKOH / g, add 5 molar parts of sebacic acid and 12 molar parts of triisopropanolamine at the same time, and heat up to 233 °C at a heating rate of 6 °C / h to continue Insulation for polymerization;

[0055] (3) When the acid value of the system reactant is reduced to 21mgKOH / g, add 8 molar parts of isophthalic acid, and continue to carry out the chain extension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com