Low cis-polybutadiene rubber, preparation method thereof, HIPS and preparation method ofHIPS

A technology of polybutadiene rubber and cis-polybutadiene, which is applied in the fields of HIPS resin and its preparation, low-cis polybutadiene rubber and its preparation, can solve corrosion, occupy a large area, and cannot be realized Balance and other issues to achieve the effect of solving corrosion problems, achieving halogen-free, balanced gloss and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the present invention provides the preparation method of above-mentioned low-cis polybutadiene rubber, wherein, the method comprises:

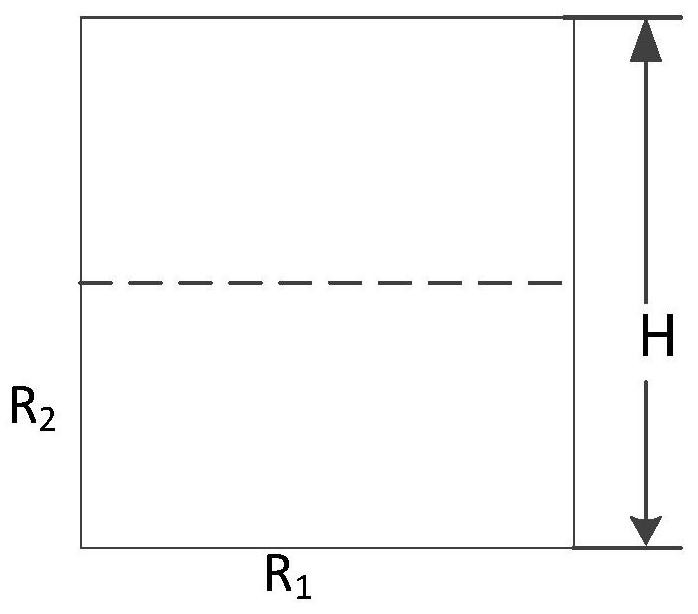

[0037] (1) In an inert solvent, in the presence of organolithium initiators, gel inhibitors and structure regulators, 1,3-butadiene is continuously fed from the reactor bottom position R 1 into the reactor to carry out the first anionic solution polymerization reaction, and the conversion rate of 1,3-butadiene reaches 20%-50%;

[0038] (2) Under the second anionic solution polymerization reaction conditions, the branched monomer is continuously fed from the feed position R of the reactor 2 is added to the reactor, and the conversion rate to 1,3-butadiene and branched monomer is above 99%, wherein, 02 -R 1 2 -R 1 is the height difference between the feed position of the branched monomer and the bottom of the reactor;

[0039] (3) The mixture obtained in step (2) is contacted with a terminator to perform a terminat...

Embodiment 1

[0101] This example is used to illustrate the low-cis polybutadiene rubber of the present invention and its preparation method.

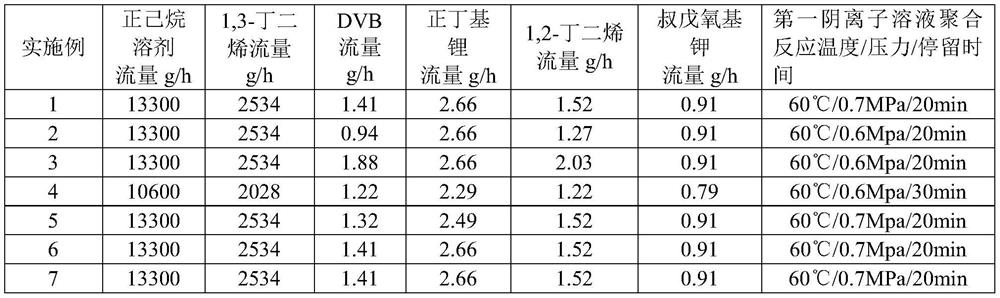

[0102] (1) Under the protection of nitrogen, continuously pour into the 16L reactor from the bottom of the reactor to R 1 Add n-hexane solvent, 1,3-butadiene monomer, 1,2-butadiene (gel inhibitor), organolithium initiator and structure regulator respectively (see Table 1 for the types and amounts, Table 1 The flow rate listed in is all measured with pure compound); And carry out the first anionic solution polymerization reaction (conditions are shown in Table 1) under specified temperature and reaction pressure;

[0103] (2) At 1 / 4 from the bottom of the reactor (R 2 at the R 2 -R 1 =1 / 4H), the n-hexane solution that will contain the branched monomer DVB is continuously added in the reactor, and carry out the second anionic solution polymerization reaction (condition sees Table 2) under specified temperature and reaction pressure

[0104] (3) Ad...

Embodiment 2-5

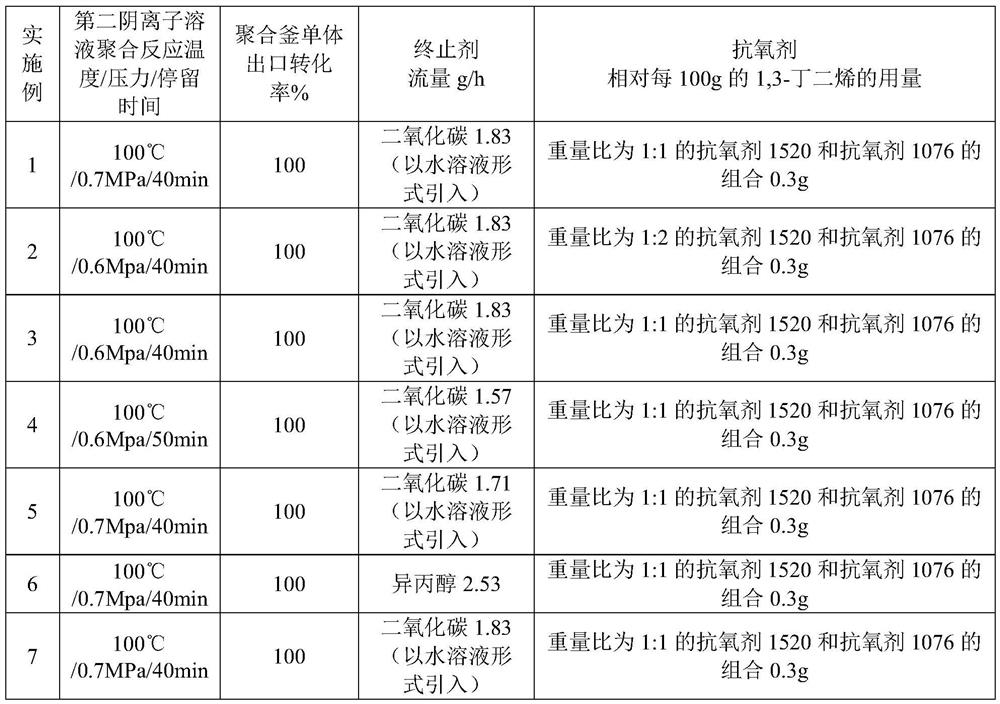

[0107] This example is used to illustrate the low-cis polybutadiene rubber of the present invention and its preparation method.

[0108] According to the method described in Example 1, the difference is that the materials and amounts shown in Table 1 are used to react, thereby obtaining the polymerization solutions PB2-PB6 of low-cis polybutadiene rubber respectively, wherein the respective low-cis polybutadiene The content of the butadiene rubber is: PB2: 15.8% by weight; PB3: 15.7% by weight; PB4: 15.7% by weight; PB5: 15.8% by weight.

[0109] After the first anionic solution polymerization and before the second anionic solution polymerization, some samples were taken out of the polymerization solution, and the finally obtained polymerization solution samples were taken out for steam condensation and desolvation treatment to obtain polymers C2-C5 for structure and performance determination. The results were See Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com