Environment-friendly wastewater filtering and recycling device for water-jet loom

A technology of a water jet loom and a recycling device, which is applied in the textile industry wastewater treatment, filtration treatment, water/sewage treatment and other directions, can solve the problems of occupying a large space, inconvenient to move and use, and unable to discharge waste residues in a centralized manner, so as to improve the filtration effect. , Improve the filtration efficiency, improve the effect of use and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

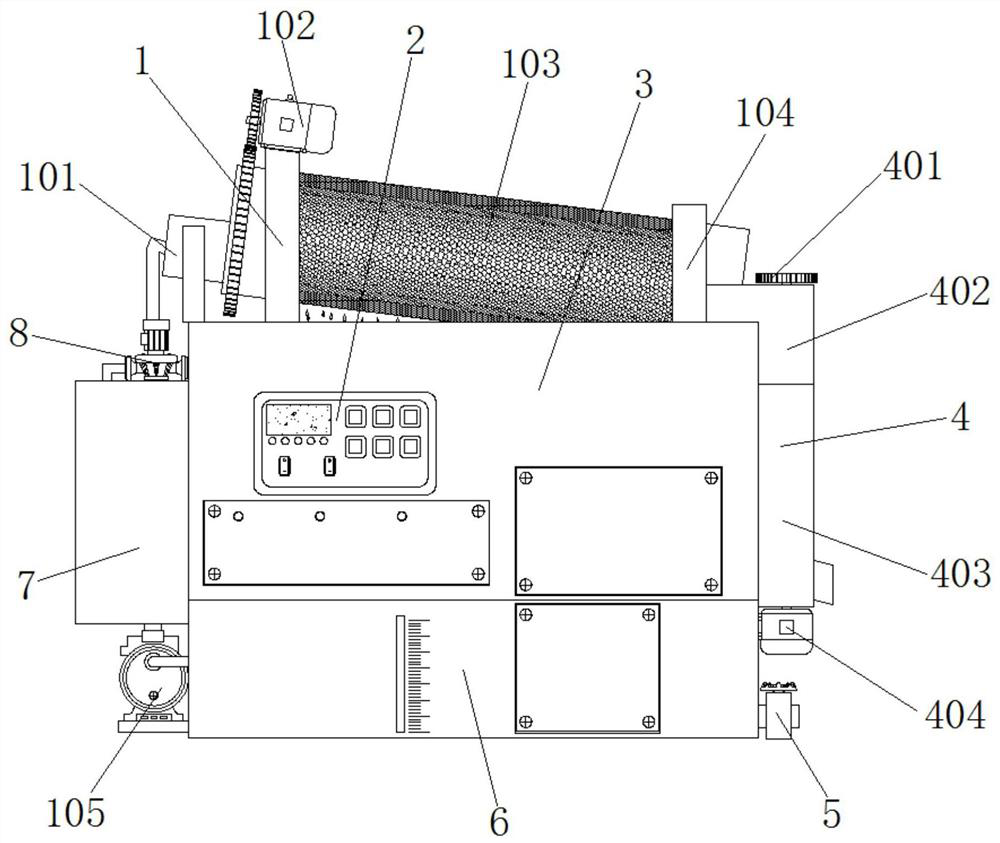

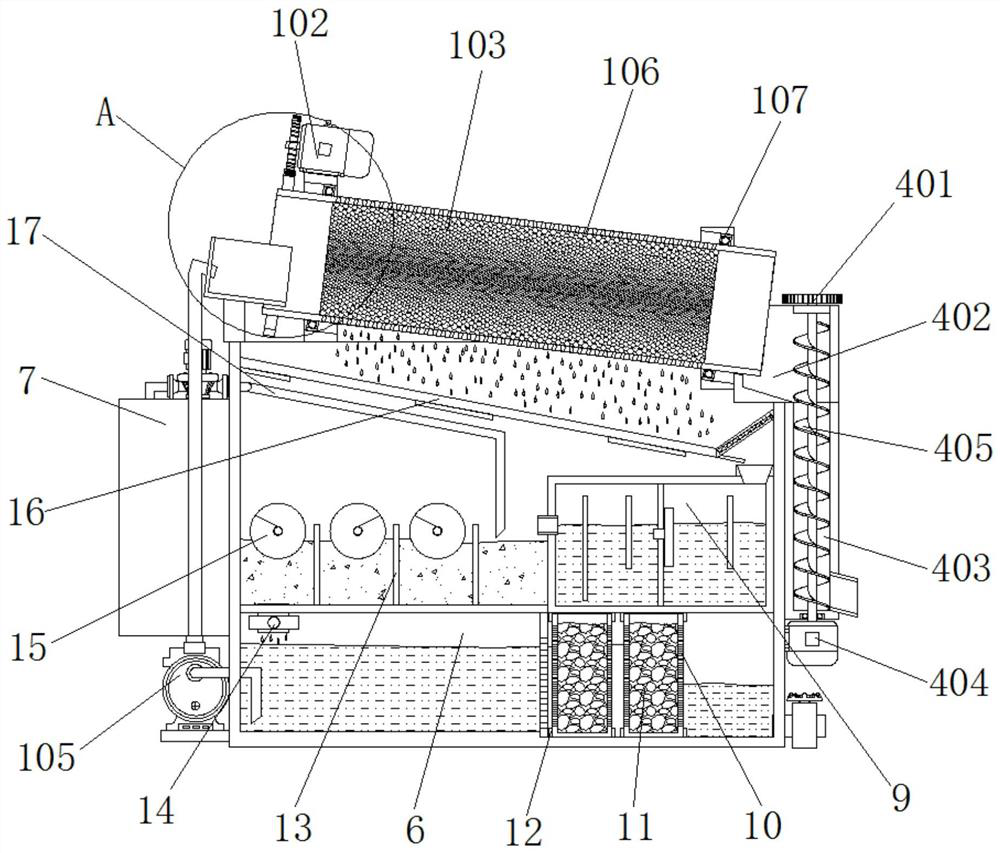

[0038] Example 1, such as Figure 1-7 As shown, the waste water produced by the water jet loom is continuously transported to the inside of the drainage chamber 101, and the first driving device 102 is controlled to drive the drum 103 to rotate slowly. plate 16, and then enters the inside of the grease trap 9 along the guide of the guide plate 16, and the waste water flows into the inner bottom of the main chamber 3 after passing through the grease trap 9, and the dirty oil in the waste water is isolated in the separation tank during the process. Inside the oil pool 9, the metering pump 8 is controlled by the control panel 2 to quantitatively transport the medicines inside the two groups of dosing chambers 7 to the inner bottom of the main chamber 3, and the sewage is chemically purified, and then the second driving device 18 is controlled. Drive the three sets of stirring paddles 15 to rotate, which helps to improve the mixing effect of the bottom sewage and the medicament in...

Embodiment 2

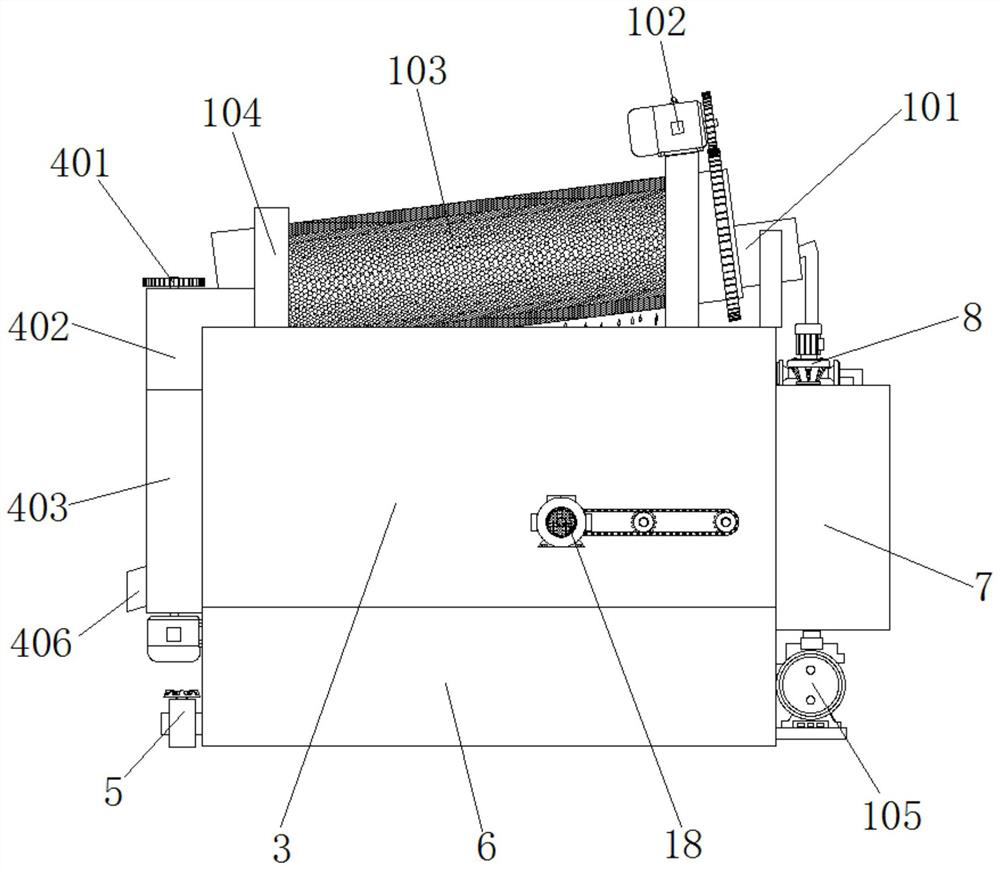

[0039] Example 2, such as Figure 1-6 As shown, when it is necessary to improve the sewage treatment effect of the device, the water pump 105 is controlled to retransmit the sewage inside the bottom bin 6 back to the inside of the drainage bin 101, so that the sewage can be filtered again, and the impact force of the sewage can also be used. , so that the waste slag filtered out of the inside of the drum 103 is more likely to fall into the inside of the collection bin 402. After the waste slag inside the drum 103 enters the inside of the collection bin 402, the drive motor 404 is controlled to drive the screw feed paddle 405 to rotate, and the two sets of screw feeders The feeding paddle 405 is driven by the transmission gear 401, so that the two sets of screw feeding paddles 405 rotate in opposite directions synchronously. With the discharge groove 403, the waste residue can be gradually discharged from the discharge port 406. There is no need to manually clean up the waste re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com