Method and system for separating sodium carbonate and sodium bromide in PTA oxidation tail gas washing tower discharge liquid

A technology for oxidizing tail gas and separation methods, applied in chemical instruments and methods, gaseous effluent wastewater treatment, alkali metal bromide, etc., can solve the problems of high wastewater treatment costs and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example is for reference figure 1 The Chinese-style test carried out by the process shown specifically includes the following steps:

[0042] (1) The washing tower discharge liquid (100kg / h) is transported to the de-sodium bicarbonate tower 1, and the pH value is adjusted to 11.6 by adding NaOH mode, and the carbon dioxide produced after removing the sodium bicarbonate is discharged from the de-sodium bicarbonate tower tower top;

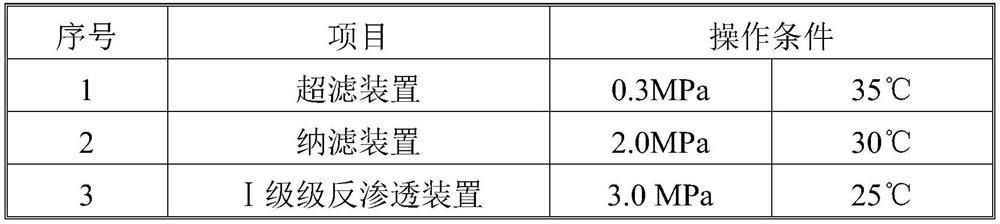

[0043] (2) The washing tower effluent (101kg / h) after removing sodium bicarbonate enters the ultrafiltration device 3 for pretreatment, removes solid impurities such as large particle molecules and suspended matter, and improves the water quality entering the follow-up system. After pretreatment The obtained ultrafiltration product water is sent to the ultrafiltration product water tank 4, and the ultrafiltration concentrated water (1kg / h) discharge device containing solid impurities;

[0044] (3) The ultrafiltration produced water (100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com