Electronic brake booster

A technology of booster and motor rotor, applied in the field of brake devices, can solve problems such as unfavorable use of vehicle space and weight reduction, unfavorable precise control of brake booster, large size of electric power assist system, etc., to achieve accurate and fast processing and Feedback, less interference, the effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

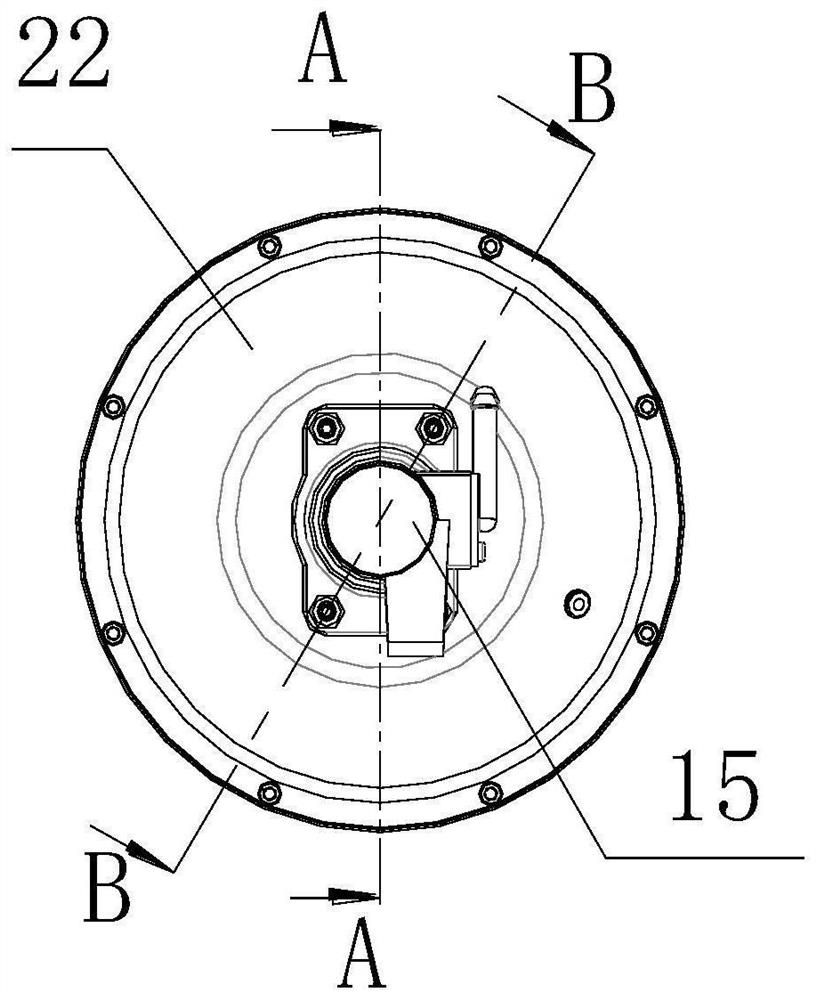

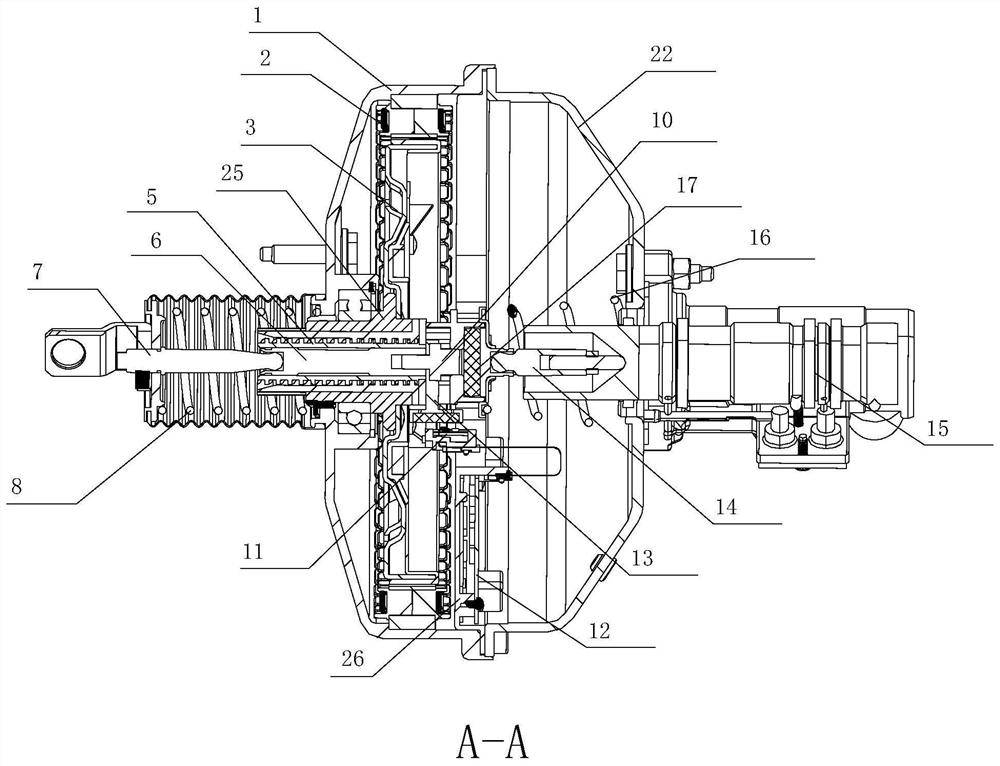

[0037] Such as Figure 1 to Figure 4 As shown, an electronically controlled brake booster for use in a vehicle braking system according to an embodiment of the present invention includes a housing, which may be made of any suitable material, for example, stamped from sheet metal like a conventional vacuum booster production. The shell is composed of two parts, the front shell 1 and the rear shell 22, and the front shell 1 and the rear shell 22 are connected and fastened by suitable fixing devices to form a whole. Preferably, the front shell 1 and the rear shell 22 are coaxial shell structures with a circular cross-section having approximately the same radius, and the two are connected by bolts.

[0038] The shell can be mounted to the vehicle body by suitable fixtures or structures. A motor is fixedly installed in the front housing 1, and the motor is composed of a stator 2 and a rotor 3, wherein the stator 2 is fixedly installed on the inner peripheral wall of the front hou...

Embodiment 2

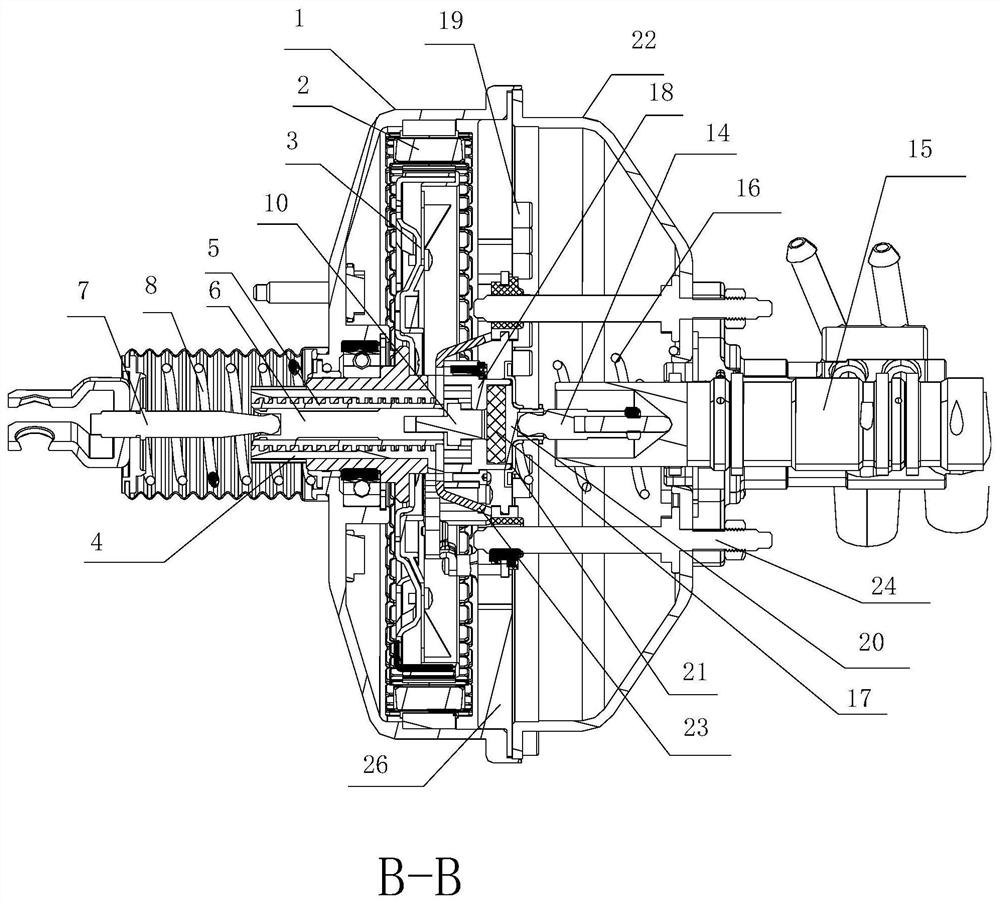

[0055] Such as Figure 5 to Figure 7 As shown, in this embodiment, the rotor 3 is rotatably coaxially installed in the front housing 1 through the bearing seat, and the rotor 3 is coaxially fixed with a nut sleeve 4, and the rotor 3 is non-rotatably fixed with the nut sleeve 4 through the connecting arm. connect. When the rotor 3 rotates, the nut sleeve 4 rotates synchronously with the rotor 3 .

[0056] The nut sleeve 4 is provided with a screw rod 5 that can rotate relative to the nut sleeve 4 , and the screw rod 5 and the nut sleeve 4 are arranged coaxially. In the initial state, one end of the screw rod 5 is threadedly connected with the nut sleeve 4 , and the other end protrudes from the front casing 1 in the axial direction and extends outward. The end of the screw rod 5 near the brake master cylinder 15 is fixedly equipped with a positioning support frame 23, and the positioning support frame 23 is sleeved and installed on the support rod 24 on the rear housing 22. Th...

Embodiment 3

[0063] The present application also discloses a vehicle equipped with the electronic brake booster disclosed in the above embodiments, and the booster is installed in a structure where the front of the vehicle is close to the chassis.

[0064] For family cars, it can replace the position of the original electronic brake booster, so that the original installation space has more space for luggage. For flat-top trucks using vacuum boosters, they can be installed in the original position where the vacuum booster was installed, and do not require accessories such as vacuum pumps, which greatly reduces the installation space and reduces the weight of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com