Engineering vehicle battery heat management system and method

A technology for heat management and engineering vehicles, which is applied in the field of engineering vehicle battery heat management systems, can solve the problems of large temperature differences and complex temperature changes in the operating environment of pure electric engineering vehicles, and achieves convenient and flexible adjustment, high cooling system efficiency, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical details and advantages of the present invention, it will now be described in conjunction with the accompanying drawings.

[0026] In order to detect the ambient temperature, this embodiment is equipped with an ambient temperature sensor, and in order to realize the function of automatically switching working conditions, this embodiment is equipped with a controller, all of which are prior art.

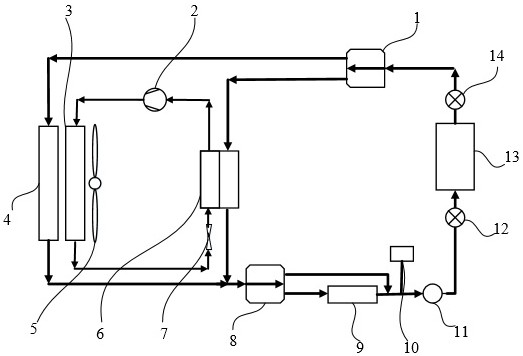

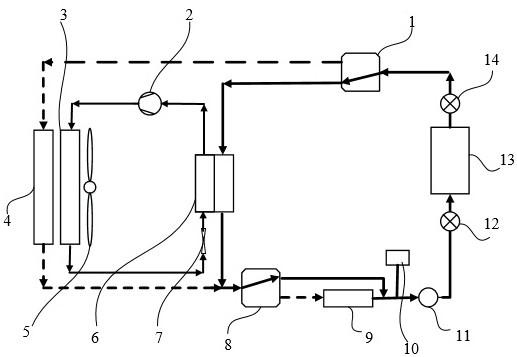

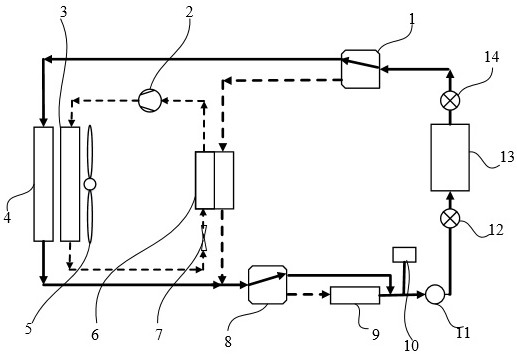

[0027] Such as figure 1 As shown, a battery heat management system for an engineering vehicle includes a battery pack 13, the battery pack 13 is provided with a water inlet and a water outlet, and the water inlet is connected to a water pump 11, and it is characterized in that it also includes an electronic three-way valve A1, electronic three-way valve B8, radiator 4, plate changer 6 and heater; the first end of the electronic three-way valve A is connected to the water outlet, and the second end is connected to the electronic three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com