Asphalt melting equipment for highway engineering

A melting equipment and engineering technology, used in roads, roads, road repair and other directions, can solve the problems of rapid melting of asphalt, reduce work efficiency, inconvenient road construction work, etc., to speed up melting speed, improve work efficiency, and reduce friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0017] The components of the present invention are generally standard parts or components known to those skilled in the art, and their structures and principles are known for the skilled in the art or learned through a conventional experimental method.

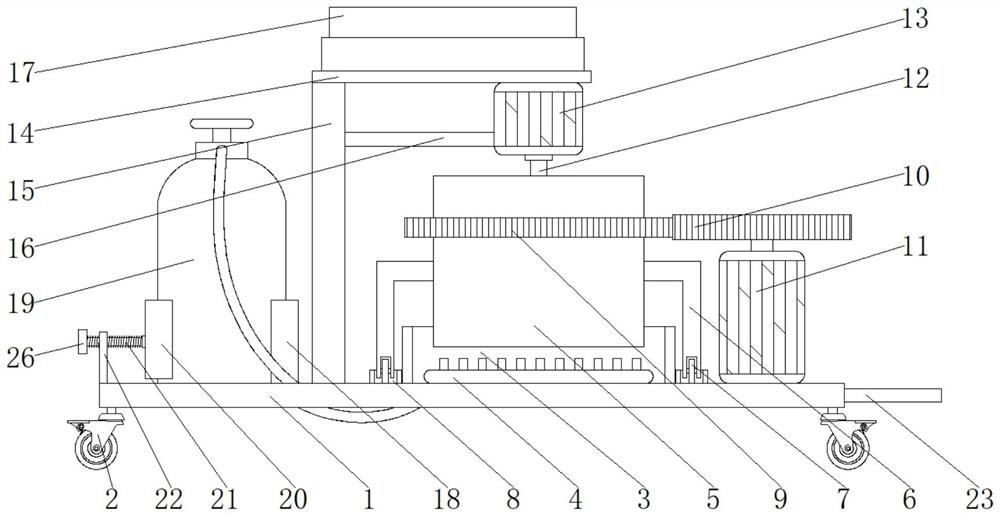

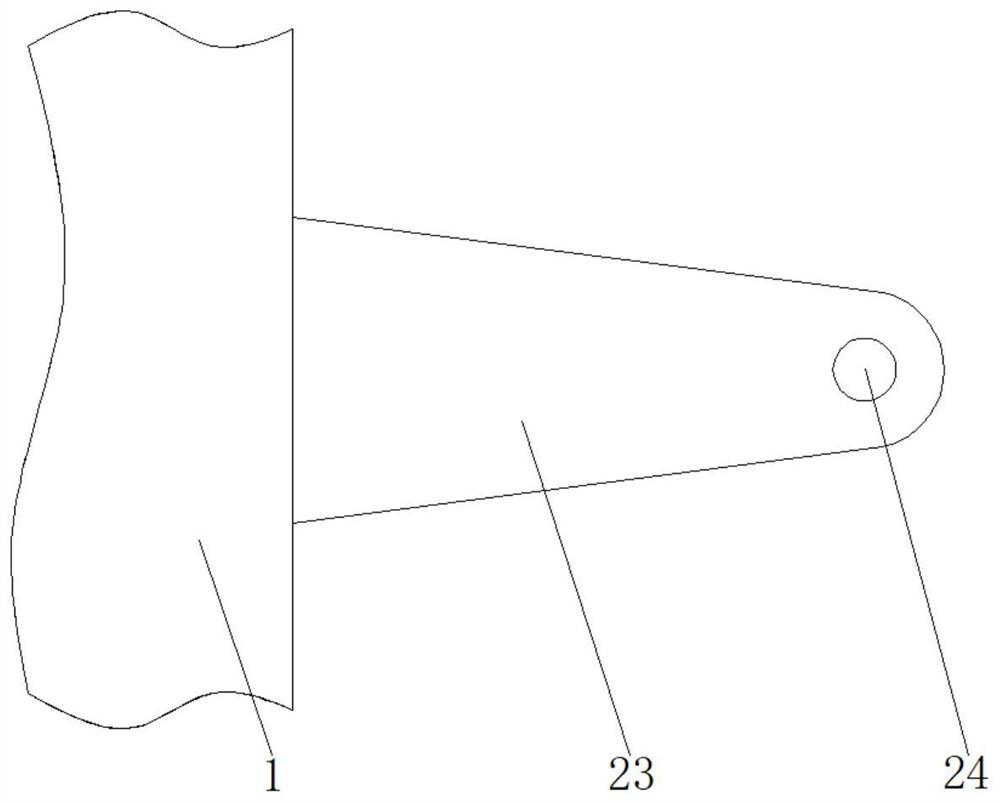

[0018] See Figure 1-3 An asphalt highway engineering melting apparatus, comprising a quadrangular base 1, the bottom plate 1 are fixedly connected with a caster 2, the top plate 1 is fixedly connected with windshield 3, located at the top of the base plate 1 and the windshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com