Preparation method of ceramic with mutton fat jade touch sense

A suet and tactile technology, applied in the field of ceramics, can solve the problems of not easy precipitation, toughness, insufficient mechanical properties, unfavorable toughness, mechanical properties, etc., and achieve the effect of smooth touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

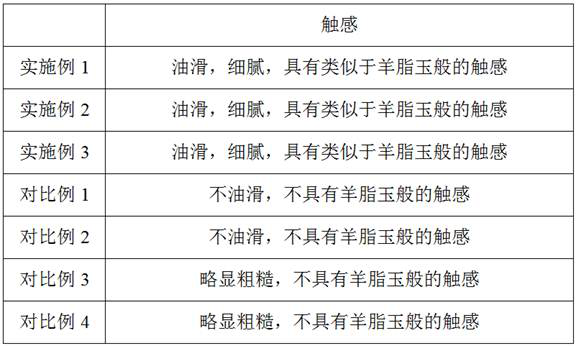

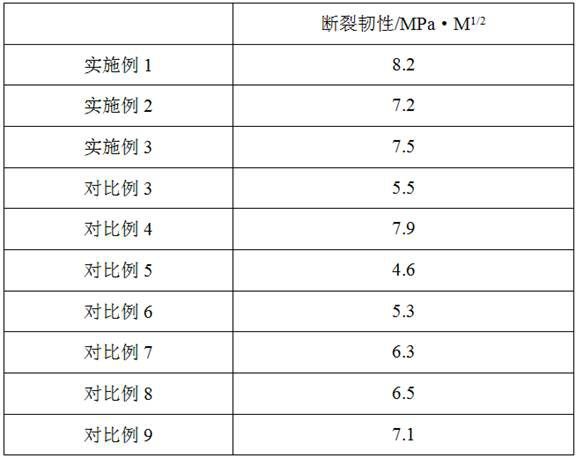

Examples

Embodiment 1

[0034] A preparation method of a ceramic with a suet jade touch, comprising the following steps;

[0035] S1, 31 parts by weight of kaolin, 23 parts by weight of pyrophyllite, 19 parts by weight of quartz sand, 12 parts by weight of calcium oxide, 8 parts by weight of wollastonite, 4 parts by weight of sintering aid, 3 parts by weight of spodumene are added to the ball mill, The ball mill is mixed evenly, after pressing, sintering at 1350 ° C for 90 minutes, and grinding to obtain a green body layer;

[0036] S2, prepare the suet jade glaze, apply the suet jade glaze to the green body layer, and the glazing amount is 200g / m 2 ;

[0037] S3, sintering at 1350 ° C for 80 minutes, to obtain a ceramic with a suet jade touch;

[0038] The suet jade glaze is made from the following raw materials in parts by weight: 28.4 parts of kaolin, 18 parts of white frit, 14 parts of pyrophyllite, 11 parts of quartz sand, 9 parts of calcium oxide, 7.6 parts of wollastonite, 6 parts of lubrica...

Embodiment 2

[0050] A method for preparing ceramics with suet jade touch, comprising the following steps;

[0051] S1, 31 parts by weight of kaolin, 23 parts by weight of pyrophyllite, 19 parts by weight of quartz sand, 12 parts by weight of calcium oxide, 8 parts by weight of wollastonite, 4 parts by weight of sintering aid, and 3 parts by weight of spodumene are added to the ball mill, Ball milling, mixing evenly, pressing, sintering at 1350°C for 90 minutes, and edging to obtain the green body layer;

[0052] S2. Prepare the suet jade glaze, apply the suet jade glaze to the green body layer, and the glaze amount is 200g / m 2 ;

[0053] S3, sintering at 1350°C for 80 minutes to obtain ceramics with suet jade touch;

[0054] The suet jade glaze is made of the following raw materials in parts by weight: 32 parts of kaolin, 14 parts of white frit, 15 parts of pyrophyllite, 12 parts of quartz sand, 10 parts of calcium oxide, 8 parts of wollastonite, 5 parts of lubricant, 3 parts of 1 part ...

Embodiment 3

[0063] A method for preparing ceramics with suet jade touch, comprising the following steps;

[0064] S1, 31 parts by weight of kaolin, 23 parts by weight of pyrophyllite, 19 parts by weight of quartz sand, 12 parts by weight of calcium oxide, 8 parts by weight of wollastonite, 4 parts by weight of sintering aid, and 3 parts by weight of spodumene are added to the ball mill, Ball milling, mixing evenly, pressing, sintering at 1350°C for 90 minutes, and edging to obtain the green body layer;

[0065] S2. Prepare the suet jade glaze, apply the suet jade glaze to the green body layer, and the glaze amount is 200g / m 2 ;

[0066] S3, sintering at 1350°C for 80 minutes to obtain ceramics with suet jade touch;

[0067] The suet jade glaze is made of the following raw materials in parts by weight: 28 parts of kaolin, 15 parts of white frit, 16 parts of pyrophyllite, 10 parts of quartz sand, 11 parts of calcium oxide, 7 parts of wollastonite, 6 parts of lubricant, 4 parts of 1 part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com