Instrument product life cycle management method and system based on identification analysis

A technology of product life cycle and management method, which is applied in the field of instrument product life cycle management method and system based on identification analysis, can solve problems that cannot constitute independent applications, improve resource utilization and service levels, reduce inventory, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

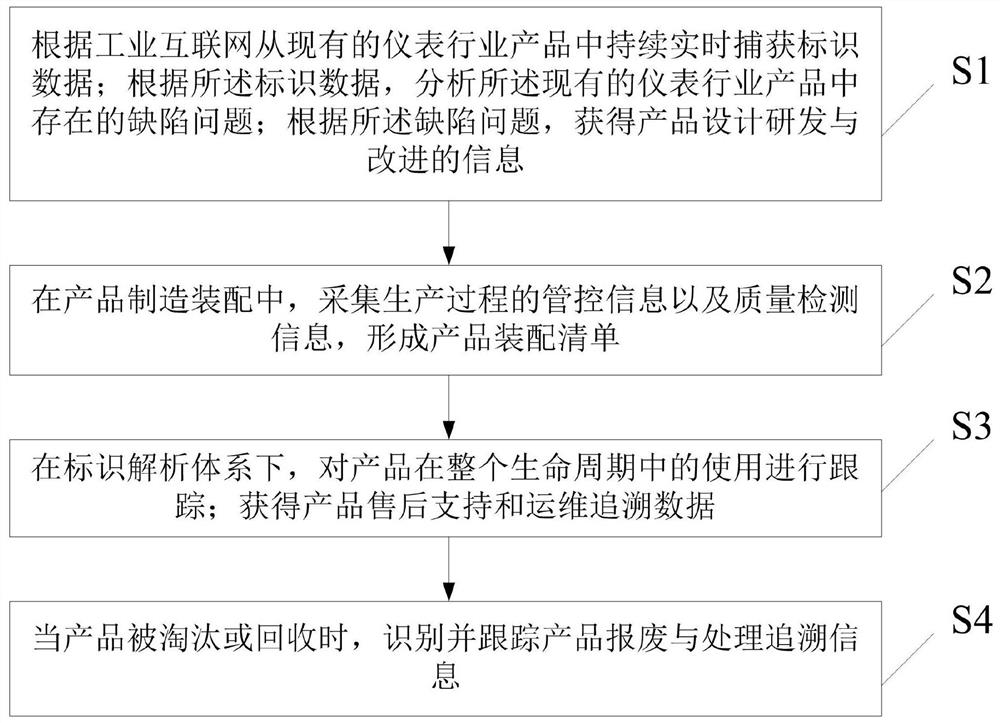

[0041] refer to figure 1 As shown, the embodiment of the present invention provides an instrument product life cycle management method based on identification analysis, including:

[0042] S1. Continuously capture identification data from existing instrument industry products in real time according to the industrial Internet; analyze the defects existing in the existing instrument industry products according to the identification data; obtain product design and development according to the defects and improved information;

[0043] S2. In product manufacturing and assembly, collect control information and quality inspection information in the production process to form a product assembly list;

[0044] S3. Under the identification analysis system, track the use of products throughout the life cycle; obtain product after-sales support and operation and maintenance traceability data;

[0045] S4. When a product is eliminated or recycled, identify and track product scrapping an...

Embodiment 2

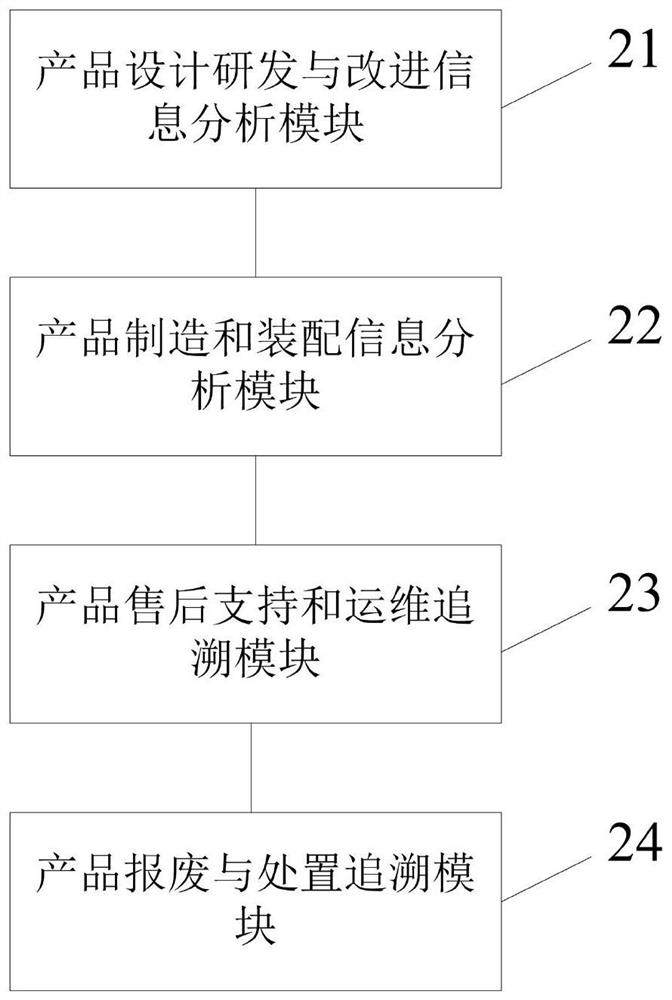

[0056] The embodiment of the present invention also provides an instrument product life cycle management system based on identification analysis, refer to figure 2 shown, including:

[0057] The product design, development and improvement information analysis module 21 is used to continuously capture identification data from existing instrument industry products in real time according to the industrial Internet; analyze the defects existing in the existing instrument industry products according to the identification data; Obtain information on product design, development and improvement based on the defects described;

[0058] The product manufacturing and assembly information analysis module 22 is used to collect control information and quality inspection information of the production process during product manufacturing and assembly to form a product assembly list;

[0059] Product after-sales support and operation and maintenance traceability module 23, used to track the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com