Flame-retardant modified polyacrylonitrile fiber

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in the direction of flame-retardant fiber, fiber type, fiber treatment, etc., and can solve problems such as flammability and secondary harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

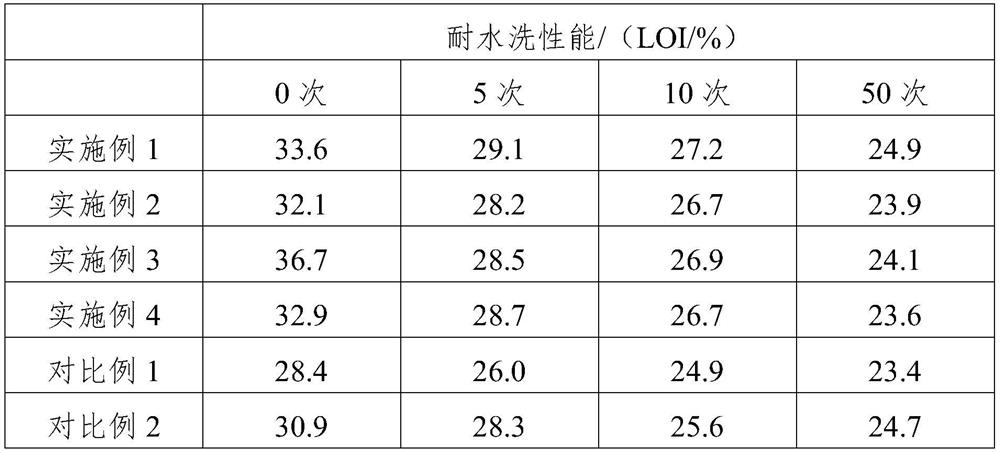

Examples

Embodiment 1

[0033] A flame-retardant modified polyacrylonitrile fiber, the preparation method of the modified polyacrylonitrile fiber comprises the steps:

[0034] (1) Aluminum borate modification: Mix ethanol and distilled water in a weight ratio of 9:1 to prepare a solvent, adjust its pH to 4.0 with acetic acid, configure a silane coupling agent with a mass fraction of 5%, and use a magnetic stirring device for the reaction The mixture was stirred for 1 h for prehydrolysis. 10 g of borate whiskers were dispersed in 50 g of distilled water by ultrasound. Add 2g of pre-hydrolyzed silane coupling agent, mix and stir for 10 minutes, and let stand for reaction for 30 minutes. After filtering and drying in a vacuum oven at 120° C. for 24 hours, silanized aluminum borate whiskers were obtained.

[0035] (2) Dissolve the modified 0.2g of silanized aluminum borate whiskers and 10g of polyacrylonitrile in 50g of N-N-dimethylformamide, stir with a constant temperature magnetic stirrer at 80°C fo...

Embodiment 2

[0039] A flame-retardant modified polyacrylonitrile fiber, the preparation method of the modified polyacrylonitrile fiber comprises the steps:

[0040] (1) Aluminum borate modification: Mix ethanol and distilled water at a weight ratio of 9:1 to prepare a solvent, adjust its pH to 4.0–5.0 with acetic acid, configure a silane coupling agent with a mass fraction of 5%, and react using a magnetic force The stirring device stirred the mixture for 1 h to pre-hydrolyze. 10 g of borate whiskers were dispersed in 50 g of distilled water by ultrasound. Add 6g of pre-hydrolyzed silane coupling agent, mix and stir for 10 minutes, and let stand for reaction for 30 minutes. After filtering and drying in a vacuum oven at 120° C. for 24 hours, silanized aluminum borate whiskers were obtained.

[0041](2) Dissolve the modified 0.4g of silanized aluminum borate whiskers and 10g of polyacrylonitrile in 60g of N-N-dimethylformamide, stir with a constant temperature magnetic stirrer at 100°C fo...

Embodiment 3

[0045] A flame-retardant modified polyacrylonitrile fiber, the preparation method of the modified polyacrylonitrile fiber comprises the steps:

[0046] (1) Aluminum borate modification: Mix ethanol and distilled water in a weight ratio of 9:1 to prepare a solvent, adjust its pH to 4.0 with acetic acid, configure a silane coupling agent with a mass fraction of 5%, and use a magnetic stirring device for the reaction The mixture was stirred for 1 h for prehydrolysis. 10 g of borate whiskers were dispersed in 50 g of distilled water by ultrasound. Add 6g of pre-hydrolyzed silane coupling agent, mix and stir for 10 minutes, and let stand for reaction for 30 minutes. After filtering and drying in a vacuum oven at 120° C. for 24 hours, silanized aluminum borate whiskers were obtained.

[0047] (2) Dissolve the modified 0.6g of silanized aluminum borate whiskers and 10g of polyacrylonitrile in 50g of N-N-dimethylformamide, stir with a constant temperature magnetic stirrer at 8°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com