Preparation method of wool blended fabric with anti-pilling and antibacterial effects

A wool blended and blended fabric technology, used in textiles and papermaking, knitting, weft knitting and other directions, can solve the problems of short service life of wool blended fabrics, increase the overall antibacterial effect, reduce production costs, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method in this embodiment can be applied to a knitting machine. For example, the following double-sided jacquard knitting machine is provided in this embodiment, and the preparation method in this embodiment can be applied to a double-sided jacquard knitting machine.

[0030] It includes the main body of the knitting machine and the upper rotary weaving disc. The bottom end of the upper rotary weaving disc is equipped with a top supporting foot. The bottom end of the top supporting foot is equipped with a lower connecting flange. The bottom of the top supporting foot The end is provided with a bottom supporting foot, and the top of the top supporting foot is provided with an upper connecting flange, and the upper connecting flange is fixedly connected with the lower connecting flange through a second fixing bolt, and the second fixing bolt is connected to the lower connecting flange. The joints of the upper connecting flange and the lower connecting flang...

Embodiment 1

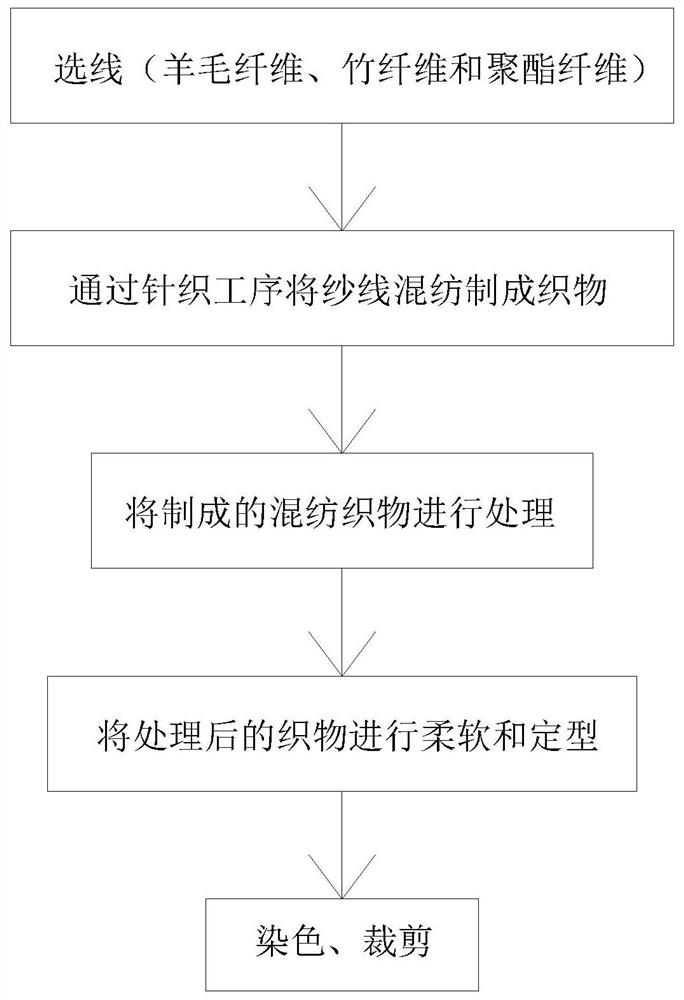

[0033] A method for preparing a wool blended fabric with anti-pilling and antibacterial effects, the preparation method of the wool blended fabric comprises the steps of:

[0034] (1) select wool fiber yarn, bamboo fiber yarn and polyester fiber yarn;

[0035] (2) Yarn is blended into fabric through knitting process;

[0036] (3) Antibacterial treatment is carried out to the blended fabric made;

[0037] (4) Softening and setting treatment of the treated fabric;

[0038] (5) Dyeing and cutting the treated fabric as required.

[0039] The bamboo fiber in described step (1) is the cellulose fiber that extracts from the bamboo of natural growth, and bamboo fiber has characteristics such as good air permeability, instantaneous water absorption, stronger wear resistance and good dyeability, It has natural antibacterial, antibacterial, anti-mite, deodorant and anti-ultraviolet functions.

[0040] The polyester fiber in the step (1) is a synthetic fiber obtained by spinning polyest...

Embodiment 2

[0049] A method for preparing a wool blended fabric with anti-pilling and antibacterial effects, the preparation method of the wool blended fabric comprises the steps of:

[0050] (1) select wool fiber yarn, bamboo fiber yarn and polyester fiber yarn;

[0051] (2) Yarn is blended into fabric through knitting process;

[0052] (3) Antibacterial treatment is carried out to the blended fabric made;

[0053] (4) Softening and setting treatment of the treated fabric;

[0054] (5) Dyeing and cutting the treated fabric as required.

[0055] The bamboo fiber in described step (1) is the cellulose fiber that extracts from the bamboo of natural growth, and bamboo fiber has characteristics such as good air permeability, instantaneous water absorption, stronger wear resistance and good dyeability, It has natural antibacterial, antibacterial, anti-mite, deodorant and anti-ultraviolet functions.

[0056] The polyester fiber in the step (1) is a synthetic fiber obtained by spinning polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com