Metal early corrosion probe and preparation method thereof

A probe and metal technology, applied in the field of material science, can solve the problems of short life, limited penetrating ability of organic coating, easy aging, etc., and achieve the effect of good density, easy control of coating thickness, and not easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

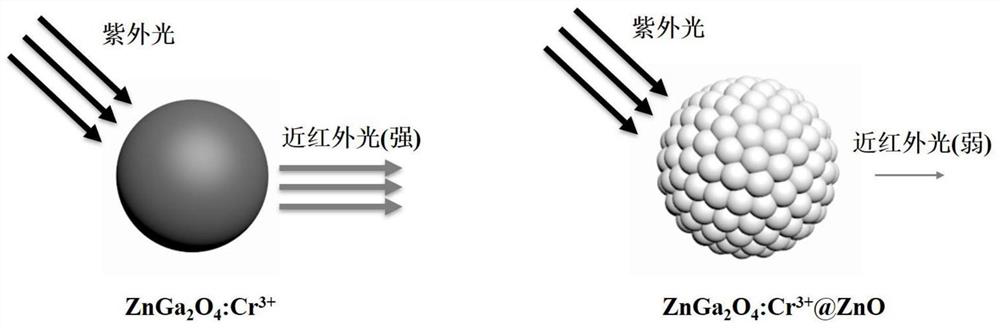

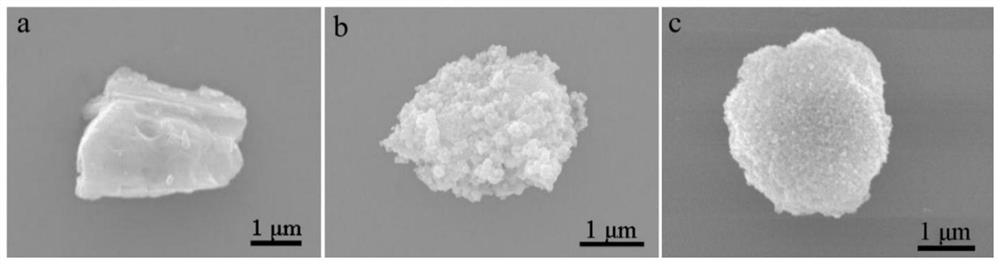

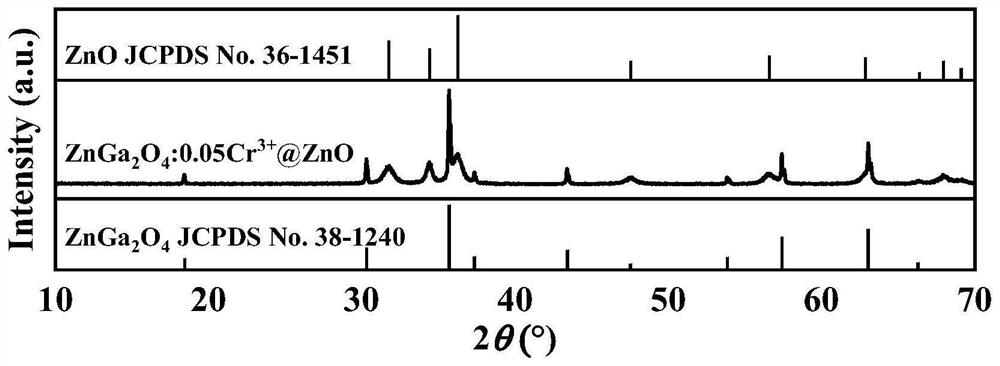

[0046] Dissolve 0.68g of zinc acetate dihydrate in 100mL of absolute ethanol to prepare zinc acetate ethanol solution; add 0.25g of sodium hydroxide to the mixed solution of absolute ethanol and deionized water (25mL of absolute ethanol and 10mL of deionized water) In, configure the sodium hydroxide solution. Weigh the existing ZnGa 2 o 4 :0.05Cr 3+ Particles 0.11g, grind until uniform and fine; then disperse it in the above-mentioned zinc acetate ethanol solution, stir and ultrasonic, make ZnGa 2 o 4 :0.05Cr 3+ The particles are uniformly dispersed in the solution without sedimentation. will contain ZnGa 2 o 4 :0.05Cr 3+ Put the suspension in a water bath and heat and stir (at a temperature of 60°C), then slowly add the prepared sodium hydroxide solution into it, after the dropwise addition is completed, seal the container containing the suspension, and continue heating and stirring for 4h . After heating and stirring, the suspension was centrifuged to obtain the bo...

Embodiment 2

[0049] Measure 1 mL of tetrabutyl titanate, dissolve it in 5 mL of absolute ethanol, and prepare tetrabutyl titanate ethanol solution. Weigh the existing ZnGa 2 o 4 :0.05Cr 3+ Grind 0.11 g of particles until uniform and fine; then disperse them into a mixed solution of absolute ethanol and deionized water (85 mL of absolute ethanol, 10 mL of deionized water), stir and sonicate to obtain a uniformly dispersed suspension; Nitric acid adjusted the pH of the suspension to 3.0. The prepared tetrabutyl titanate ethanol solution was slowly added to the suspension, and the suspension was continuously stirred during the addition process, and then the container containing the suspension was closed and the stirring was continued for 2 hours. After the stirring, the suspension was centrifuged to obtain the bottom precipitate, washed twice with absolute ethanol, dried at 50°C for 24h, and then the obtained powder was calcined at 500°C for 2h in an air atmosphere. Finally, the fluoresce...

Embodiment 3

[0052] Dissolve 0.68g of zinc acetate dihydrate in 100mL of absolute ethanol to prepare zinc acetate ethanol solution; add 0.25g of sodium hydroxide to the mixed solution of absolute ethanol and deionized water (25mL of absolute ethanol and 10mL of deionized water) In, configure the sodium hydroxide solution. Weigh the existing Y 2 o 3 :Eu 3+ Granules 0.11g, grind until uniform and fine; then disperse it into the above-mentioned zinc acetate ethanol solution, stir and sonicate to make Y 2 o 3 :Eu 3+ The particles are uniformly dispersed in the solution without sedimentation. will contain Y 2 o 3 :Eu 3+ Put the suspension in a water bath and heat and stir (at a temperature of 60°C), then slowly add the prepared sodium hydroxide solution into it, after the dropwise addition is completed, seal the container containing the suspension, and continue heating and stirring for 4h . After heating and stirring, the suspension was centrifuged to obtain the bottom precipitate, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com