Curved functional film structure and method for producing same

A technology of functional film and curved part, applied in the field of three-dimensional functional film structure and its manufacturing, can solve problems such as undisclosed pressure-sensitive or temperature-sensitive buttons, and achieve the effects of reducing size, high durability, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

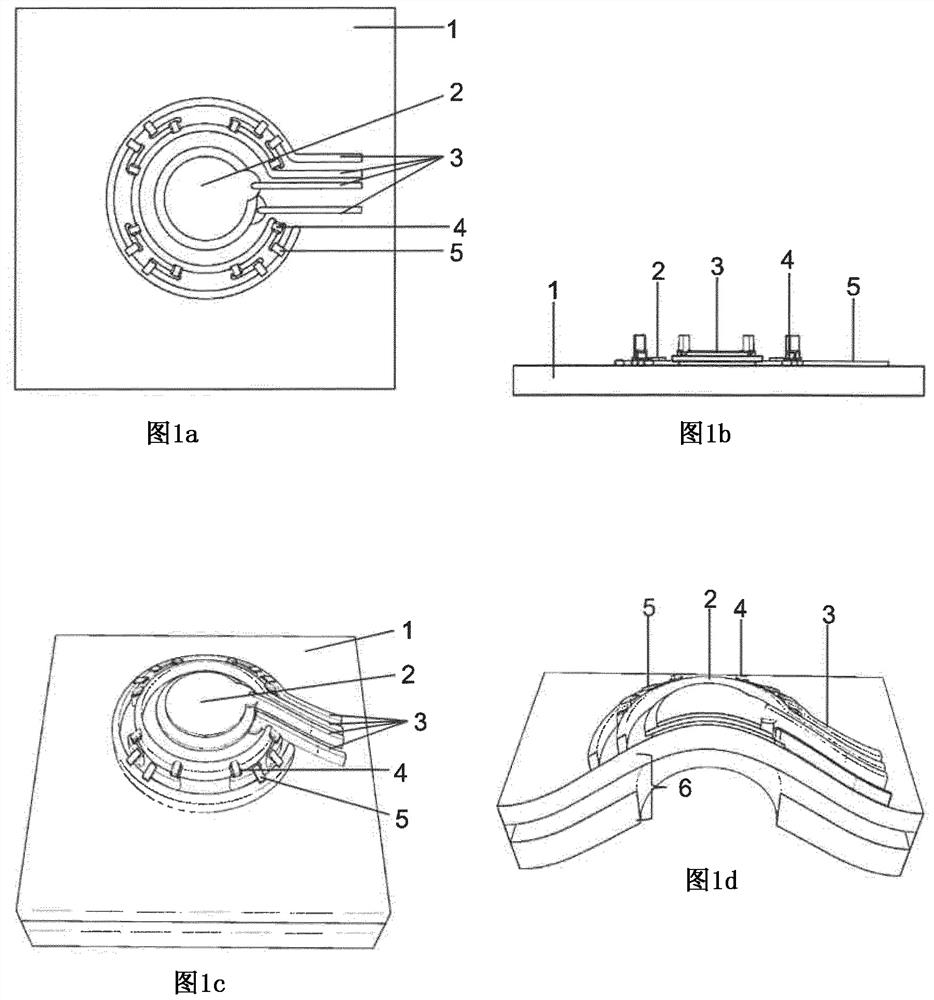

example 1

[0189] Sensor buttons with diameters of 10 mm, 15 mm and 20 mm were provided on a thermoplastic deformable film substrate (PMMA film, thickness: 175 μm). The round button is made of a sufficiently transparent material as a sandwich structure with a base electrode layer, a ferroelectric sensor layer, and a cover electrode layer. Electrical contact with the outside is made via a ring conductor path. For the backlight, the LED light source is mounted outside the actual sensing part. LEDs integrated directly next to the sensor section require a very small LED design. These are supplied using pico-LEDs (SMD components) and have very small dimensions (1mm x 0.6mm) and a small thickness of 0.2mm. The sensor button illumination was pre-checked using optical simulations using a commercial ray tracing tool (OpticStudio). Based on simulations, place a sufficient number of pico-LEDs and an equivalent number of series resistors outside the button touch portion.

[0190] The fabrication...

example 2

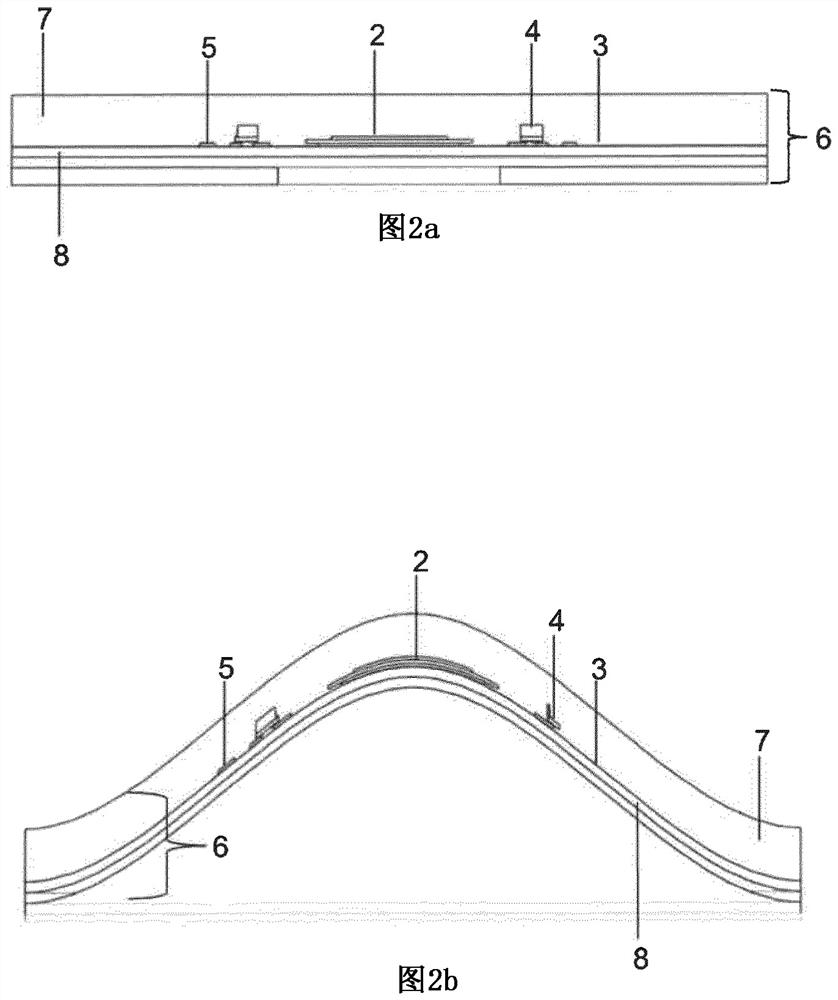

[0194] This example describes a method for fabricating a backlit pressure- or temperature-sensitive membrane sensor button with a 3D shape (see Figure 2).

[0195] First, a membrane composite is fabricated. The two-dimensional bonding of the functional film (eg PEN) and carrier film (eg ABS) is performed in a roll-to-roll process by wet lamination. In the lamination process, a liquid laminating adhesive is first applied to one of the two films, pre-dried and then the so-coated film is joined to the other film under the influence of pressure and / or temperature superior.

[0196] Then, fabricate the membrane sensor button. The individual layers of the membrane sensor button (sensor interlayer, conductive paths) and decorative ink are applied in a structured manner to a pre-cut membrane using an additional screen printing process including intermediate drying through a mask (screen / stencil) Composite materials (such as PEN / ABS). The printing sequence was as follows: On the prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com