Strengthening and deviation rectifying equipment for grouting composite foundation

A composite foundation and grouting technology, used in drilling equipment, drilling equipment and methods, infrastructure engineering and other directions, can solve the problems of easy collapse of foundation pile holes, and achieve the effect of improving connection strength and good supporting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The application will be described in further detail below in conjunction with all the accompanying drawings.

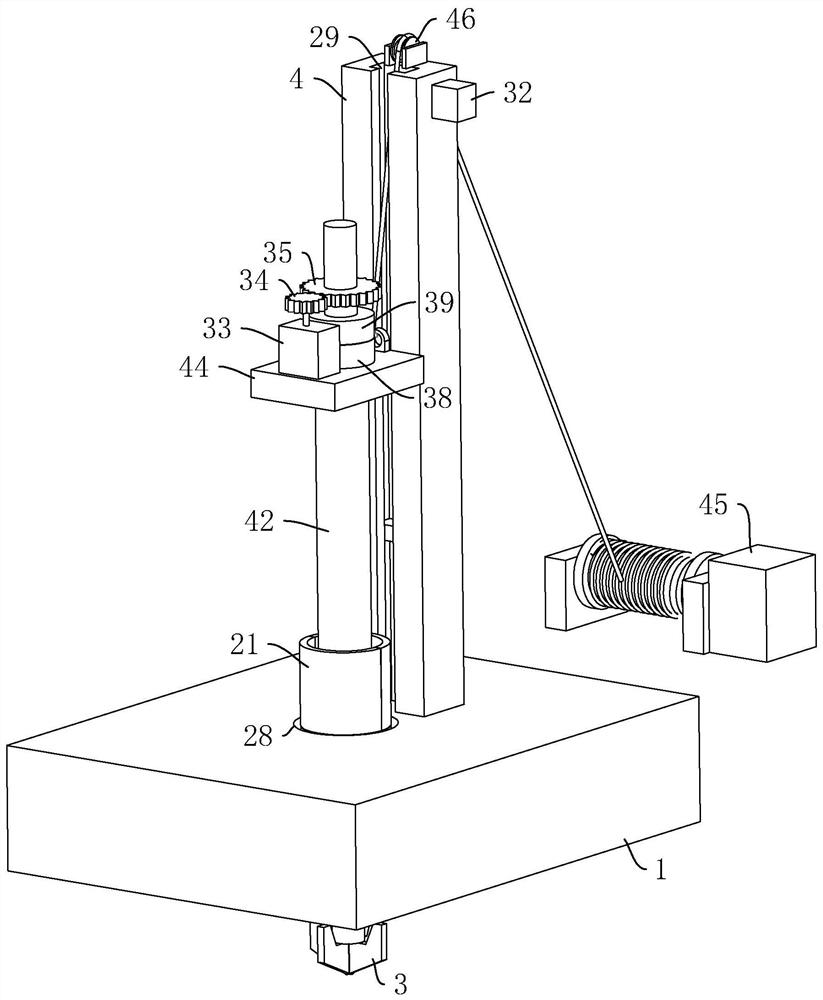

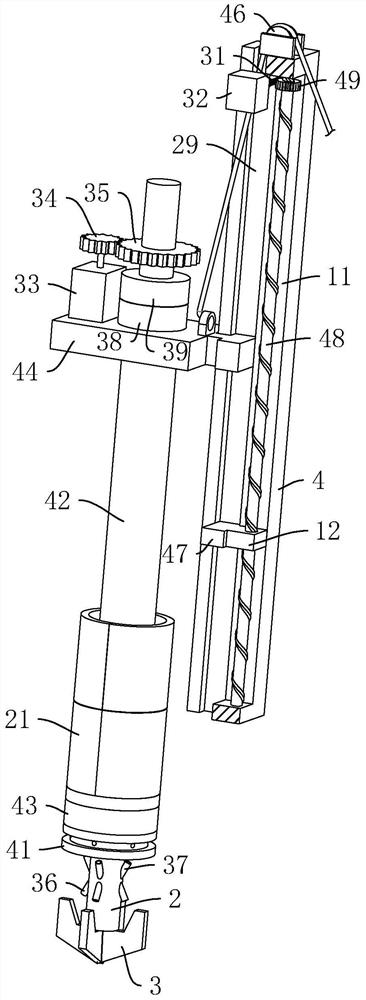

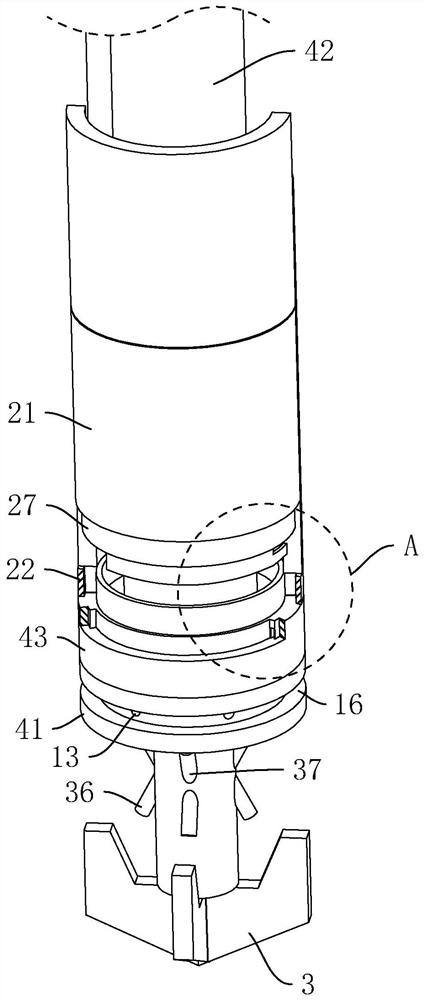

[0036] The embodiment of this application discloses a kind of equipment for strengthening and correcting the grouting composite foundation. figure 1 with figure 2, comprising a drill floor 1 located on the foundation level at the periphery of the building, the upper surface of the drill floor 1 is provided with a vertical drill floor hole 28, and the inner diameter of the drill floor hole 28 is greater than the inner diameter of the foundation pile hole to be excavated and formed , Drill floor hole 28 is socketed with vertical drill rod 2, drill rod 2 bottoms are detachably connected with drill body 3, drill body 3 rotates around the drill rod 2 axis, so that foundation pile hole drilling is formed. The upper surface of the drill floor 1 is fixedly connected with a vertical guide column 4 at one side of the drill floor hole 28, and the guide column 4 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com