A method for manufacturing metal hollow sphere composite materials by adding and subtracting materials

A technology for metal hollow spheres and composite materials, which is applied in the field of composite material addition and subtraction manufacturing, and the field of metal hollow sphere composite material addition and subtraction manufacturing. It is difficult to take into account the functional characteristics, and it is difficult to ensure high machining accuracy, etc., to achieve the effect of controllable structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

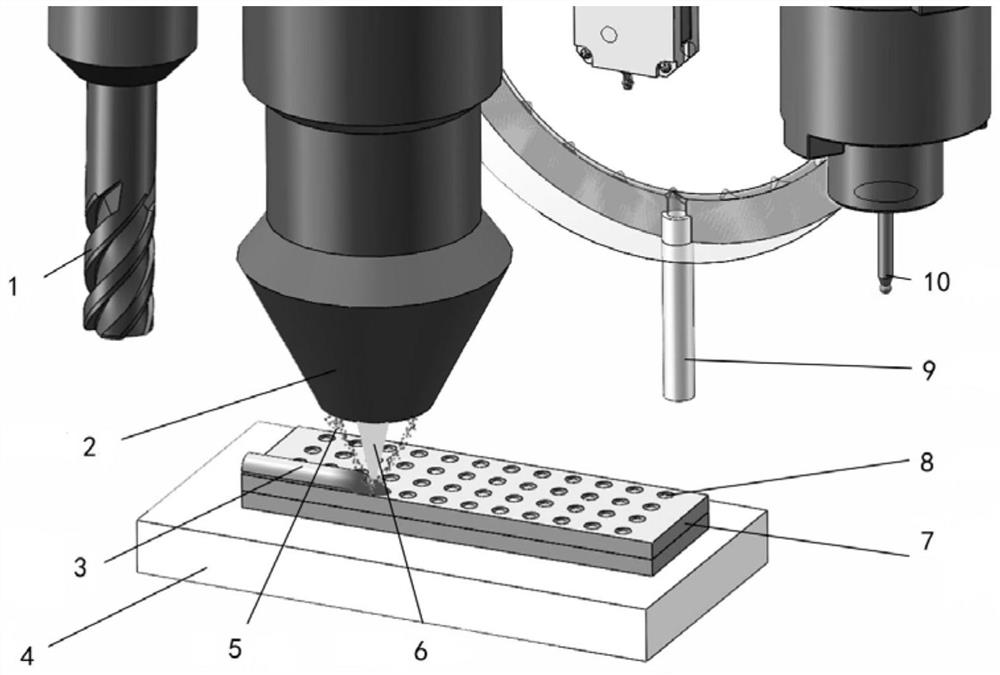

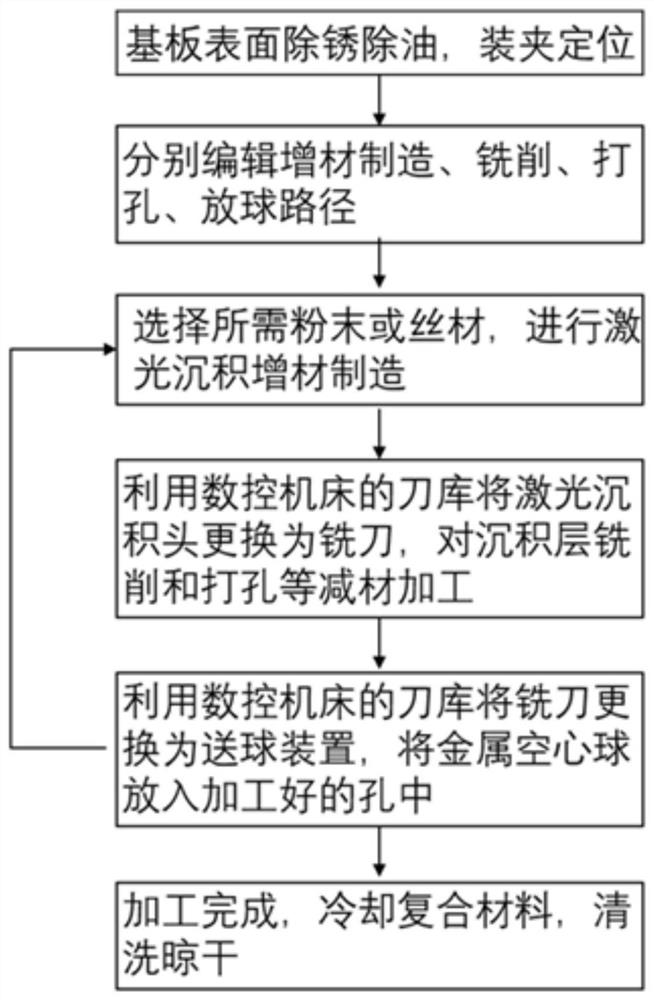

[0027] The present invention proposes a method for manufacturing metal hollow sphere composite material adding and subtracting materials, which utilizes the principle of multi-level and multi-scale strengthening and toughening of composite materials, combined with advanced manufacturing technology for adding and subtracting materials, so that materials and structures can be fully reflected in the manufacturing process Design intent, to achieve the integrated design and manufacture of components, structures and functions in the true sense.

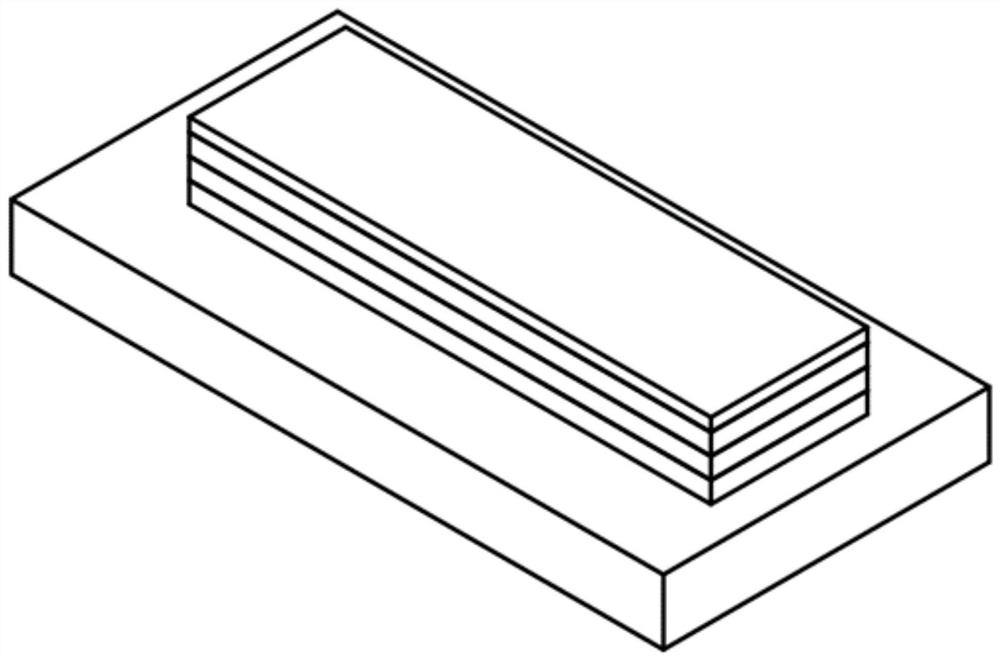

[0028] In order to achieve the above object, the present invention provides a method for manufacturing a metal hollow sphere composite material increase and decrease material. The invention will use advanced additive and subtractive composite precision manufacturing technology to form individually de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com