A metal casting derusting recovery device

A technology of metal castings and recycling devices, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of manpower adding quartz stones, impossibility, rust removal, etc., and prolong the service life , convenient and thorough rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

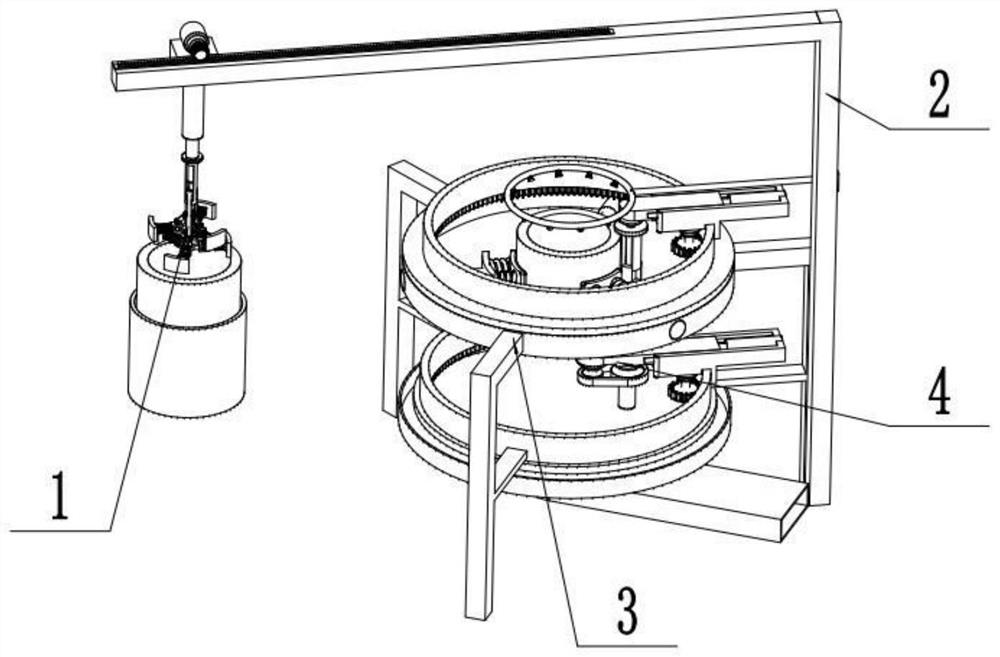

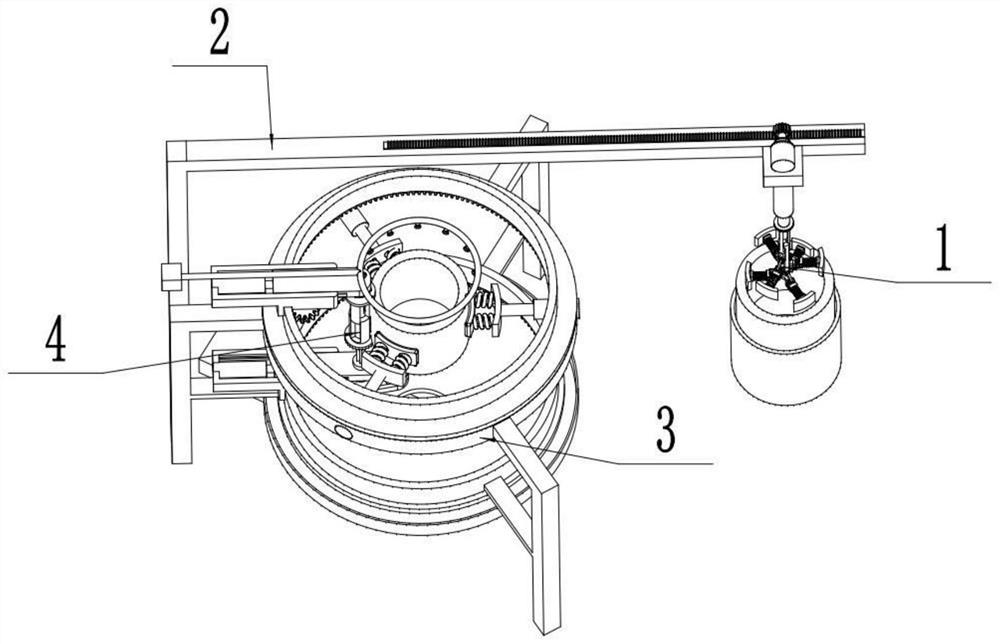

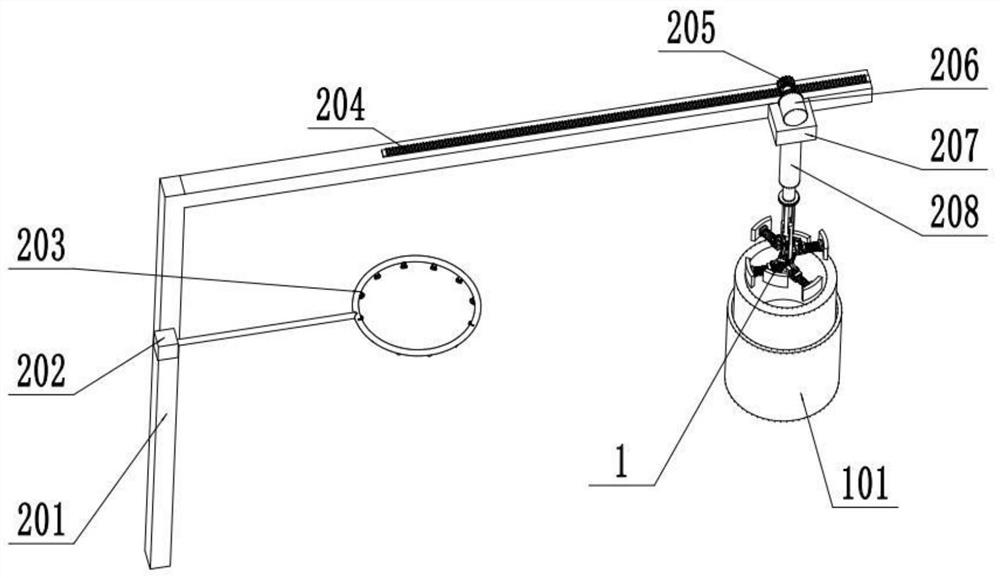

[0015] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 A metal casting derusting recovery device shown includes a pick-and-place component 1, a moving component 2, a clamping component 3, and a rust-removing component 4, wherein the moving component 2 is an installation platform for the pick-and-place component 1, and the clamping component 3 is set Below the mobile assembly 2, the derusting assembly 4 is installed on the clamping assembly 3, the mobile assembly 2 includes a mobile unit, a flushing unit and a support frame 201 for supporting, the mobile unit and the flushing unit are all installed on the support frame 201, The pick-and-place assembly 1 includes a pick-up unit for clamping castings and a storage bucket 101 for containing chemical cleaning liquid. The pick-up unit is fixedly installed on the mobile unit, and the storage bucket 101 is arranged below the pick-up unit. Component 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com