Preparation method of degradable piezoelectric fiber stent and product thereof

A technology of piezoelectric fibers and fiber membranes, which is applied in the field of preparation of degradable piezoelectric fiber scaffolds, can solve the problems of conductive hydrogel biocompatibility and poor material degradability, and achieve suitable cell attachment, simple method, and cell The effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of degradable piezoelectric fiber scaffold

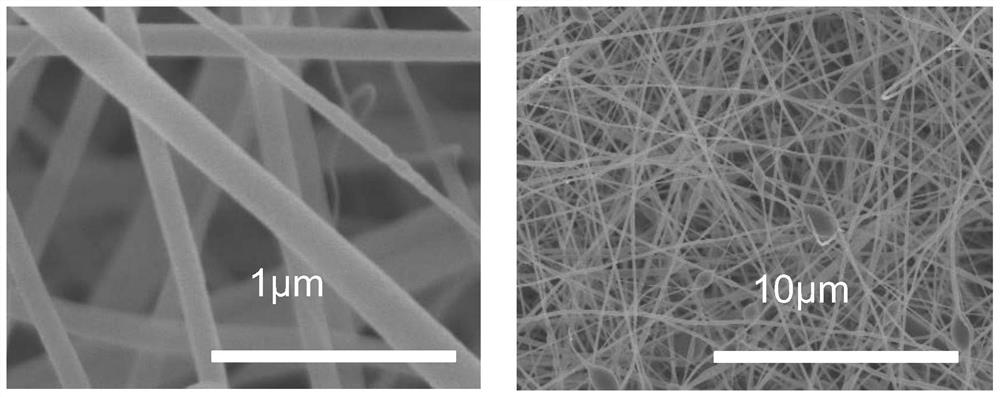

[0031] (1) Dissolve gelatin powder in a mixed solution of N,N-dimethylformamide: formic acid = 1:9 (v / v) to prepare a gelatin solution with a mass fraction of 20%; use a syringe to draw about 5mL of gelatin solution, insert a needle with a specification of 21G, and place it in a spinning machine; set the spinning parameters: distance 12cm, voltage 18kV. After spinning, the fiber membrane was removed and dried in an oven at 40° C. for 30 minutes. The SEM image of the fiber membrane is shown in figure 1 As shown, it can be seen from the SEM image that the surface of the gelatin fiber is smooth and uniform in thickness, and the diameter of the fiber filament is about 150 nm.

[0032] (2) Place the gelatin fiber membrane in saturated glutaraldehyde steam, cross-link for 24 hours at 25°C, take it out after cross-linking, place it in a fume hood for 30 minutes to volatilize the glutaraldehyde and dry it to o...

Embodiment 2

[0033] Example 2 Preparation of degradable piezoelectric fiber scaffold

[0034] (1) Dissolve gelatin powder in a mixed solution of N,N-dimethylformamide:formic acid=4:6 (v / v), and prepare a gelatin solution with a mass fraction of 30%; use a syringe to draw about 5mL of gelatin solution, insert a needle with a specification of 21G, and place it in a spinning machine; set the spinning parameters: distance 12cm, voltage 18kV. After spinning, the fiber membrane was removed and dried in an oven at 40° C. for 30 minutes. The SEM image of the fiber membrane is shown in figure 1 As shown, it can be seen from the SEM image that the surface of the gelatin fiber is smooth and uniform in thickness, and the diameter of the fiber filament is between 200nm and 500nm.

[0035] (2) Place the gelatin fiber membrane in saturated glutaraldehyde steam, cross-link for 24 hours at 25°C, take it out after cross-linking and place it in a fume hood for 30 minutes to volatilize the glutaraldehyde an...

Embodiment 3

[0036] Example 3 Preparation of degradable piezoelectric fiber scaffold

[0037] (1) Dissolve gelatin powder in a mixed solution of N,N-dimethylformamide: formic acid = 1:9 (v / v) to prepare a gelatin solution with a mass fraction of 30%; use a syringe to draw about 5mL of gelatin solution, insert a needle with a specification of 21G, and place it in a spinning machine; set the spinning parameters: distance 12cm, voltage 18kV. After spinning, the fiber membrane was removed and dried in an oven at 40° C. for 30 minutes. The surface of the fiber gelatin fiber is smooth and uniform in thickness, and the diameter of the fiber filament is about 200nm.

[0038] (2) Place the gelatin fiber membrane in saturated glutaraldehyde steam, cross-link for 24 hours at 25°C, take it out after cross-linking, place it in a fume hood for 30 minutes to volatilize the glutaraldehyde and dry it to obtain a degradable piezoelectric fiber scaffold. The fiber scaffold has Good piezoelectricity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com