Zero trans fatty acid soybean oil and production process thereof

A fatty acid and soybean oil technology, applied in the field of edible oil, can solve problems such as toxicity and even carcinogenicity, high food safety risk, and increased incidence of cardiovascular diseases such as coronary heart disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare antioxidant, the preparation method of antioxidant composition comprises the steps:

[0031] Step 1: Add 100mL of acetone into the flask, then add 0.5mol of N-bromosuccinimide to fully dissolve in acetone, add 0.5mol of carnosic acid into the flask, react at 60°C for 30min, and obtain by fractional distillation Intermediate product 1, intermediate product 1 was added to 200mL of 15% sodium hydroxide aqueous solution and hydrolyzed to obtain intermediate product 2;

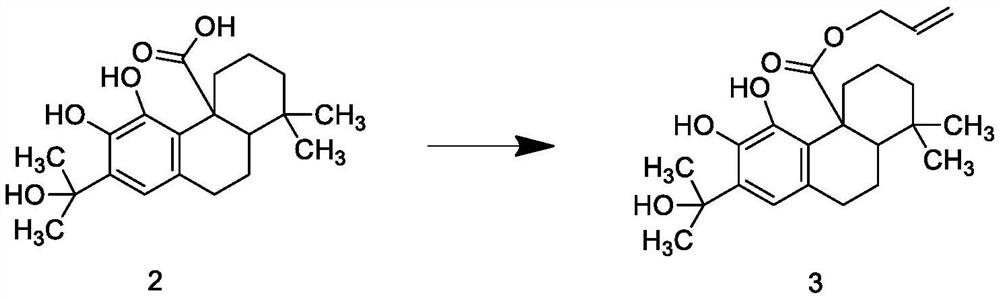

[0032] Step 2: Dissolve 0.5 mol of intermediate product 2 in 100 mL of toluene, add allyl alcohol, react with 0.08 mol of p-toluenesulfonic acid as a catalyst and 125°C for 45 minutes, and obtain intermediate product 3 by fractional distillation and concentration;

[0033] Step 3: Put 100 mL of dichloromethane into a flask, add 0.5 mol of intermediate product 3 and 0.5 mol of gallic acid into the flask, fully dissolve, then add dicyclohexylcarbodiimide and 4-dimethylaminopyridine, and heat to reflux ...

Embodiment 2

[0037] Prepare antioxidant, the preparation method of antioxidant composition comprises the steps:

[0038]Step 1: Add 100mL of acetone into the flask, then add 0.5mol of N-bromosuccinimide to fully dissolve in acetone, add 0.5mol of carnosic acid into the flask, react at 70°C for 35min, and obtain Intermediate product 1, intermediate product 1 was added to 200mL of 15% sodium hydroxide aqueous solution and hydrolyzed to obtain intermediate product 2;

[0039] Step 2: Dissolve 0.5 mol of intermediate product 2 in 100 mL of toluene, add allyl alcohol, react with 0.08 mol of p-toluenesulfonic acid as a catalyst and 130°C for 50 minutes, and obtain intermediate product 3 by fractional distillation and concentration;

[0040] Step 3: Put 100 mL of dichloromethane into a flask, add 0.5 mol of intermediate product 3 and 0.5 mol of gallic acid into the flask, fully dissolve, then add dicyclohexylcarbodiimide and 4-dimethylaminopyridine, and heat to reflux 11.5h, dichloromethane was ...

Embodiment 3

[0044] Prepare antioxidant, the preparation method of antioxidant composition comprises the steps:

[0045] Step 1: Add 100mL of acetone into the flask, then add 0.5mol of N-bromosuccinimide to fully dissolve in acetone, add 0.5mol of carnosic acid into the flask, react at 80°C for 45min, and obtain Intermediate product 1, intermediate product 1 was added to 200mL of 15% sodium hydroxide aqueous solution and hydrolyzed to obtain intermediate product 2;

[0046] Step 2: Dissolve 0.5 mol of intermediate product 2 in 100 mL of toluene, add allyl alcohol, react with 0.08 mol of p-toluenesulfonic acid as a catalyst and 130° C. for 60 minutes, and obtain intermediate product 3 by fractional distillation and concentration;

[0047] Step 3: Put 100 mL of dichloromethane into a flask, add 0.5 mol of intermediate product 3 and 0.5 mol of gallic acid into the flask, fully dissolve, then add dicyclohexylcarbodiimide and 4-dimethylaminopyridine, and heat to reflux 12h, dichloromethane was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com