Methods of generating and testing aqueous gas streams

A gas and water flow technology, applied in chemical instruments and methods, preparation of test samples, analysis of gas mixtures, etc., can solve the problem of maintaining the required concentration of dissolved water-containing gas, difficult to limit atmospheric exposure of corrosive and toxic gas substances, and changing And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

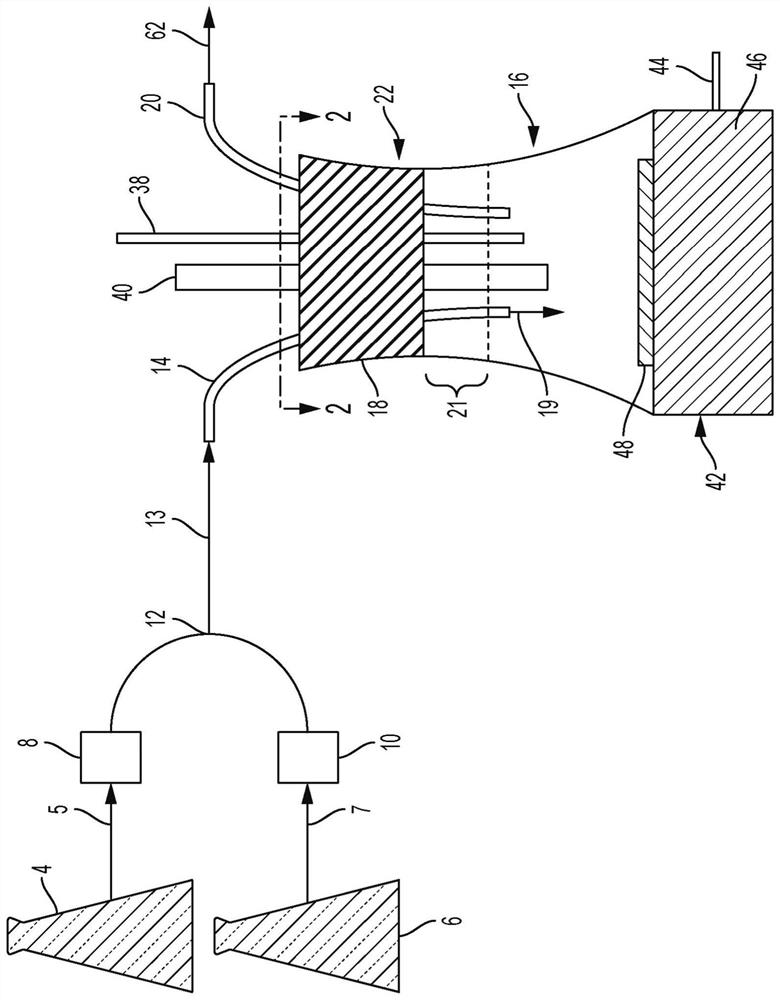

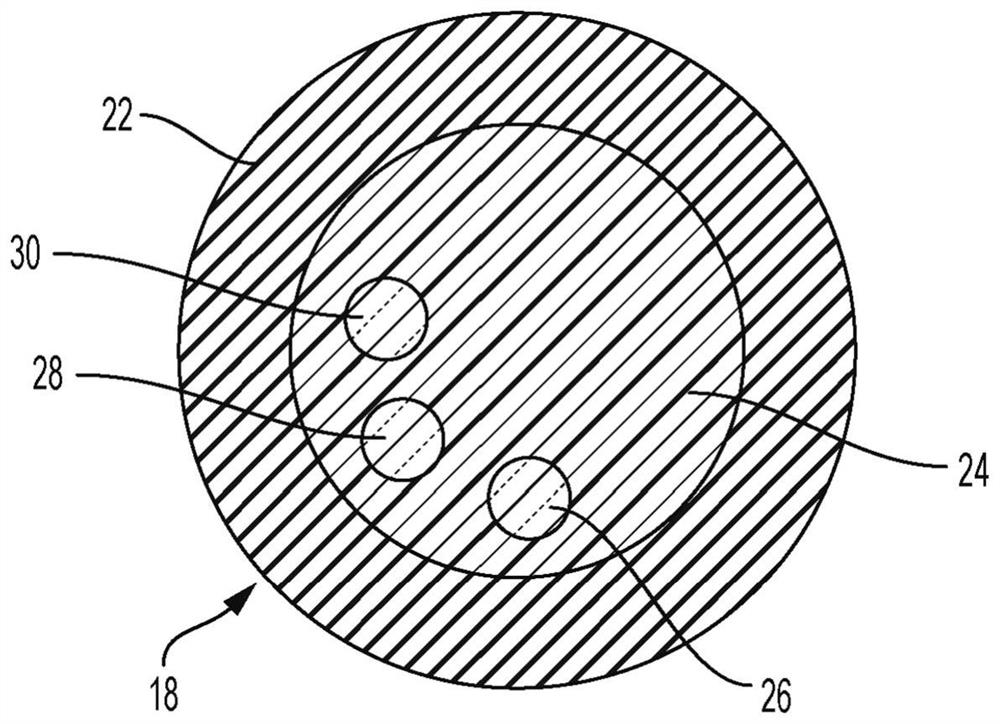

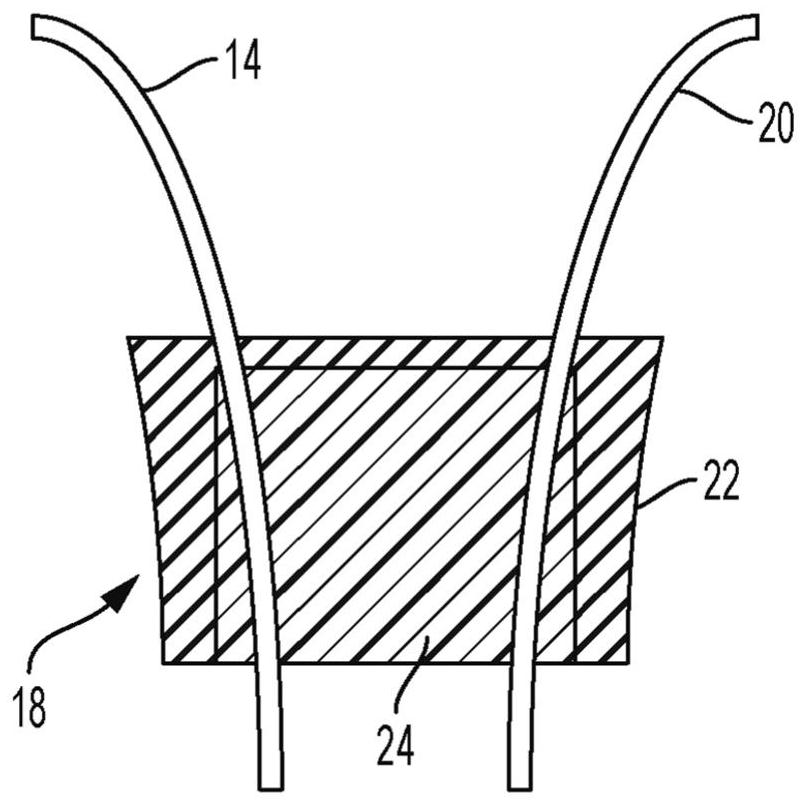

Method used

Image

Examples

example

[0050] Formation of CO from aqueous salt precursor solution and aqueous acid precursor solution 2 The reaction is described in Reaction Mechanism 1 as follows:

[0051] Overall response:

[0052]

[0053] Reaction steps:

[0054]

[0055]

[0056]

[0057] In this example, sodium carbonate (Na 2 CO 3 ) is used as aqueous salt precursor solution, sulfuric acid (H 2 SO 4 ) was used as an aqueous acid precursor solution to generate CO 2 , sodium sulfate (Na 2 SO 4 ) and water. The results for Reaction Mechanism 1 are shown in Tables 1A and 1B below:

[0058]

[0059] Tables 1A and 1B show the different concentrations of CO produced in three separate experiments 2 Precursor and final solution concentrations for aqueous solutions. CO 2 The concentration range is 2mM to 10mM. These experiments were performed at 25°C with a total flow rate of 20 mL / min (10 mL / min for each precursor solution). The resulting pressure generated in the self-pressurized flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com