Film bulk acoustic wave device and preparation method thereof

A thin-film bulk acoustic wave and thin-film bulk technology, applied in the field of thin-film bulk acoustic wave devices and their preparation, can solve problems such as large energy consumption of bulk acoustic wave filters, and achieve the effects of reducing energy consumption, reducing driving voltage, and solving the problem of thin film layer shedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with specific embodiments, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

[0059] The present invention is described in detail below.

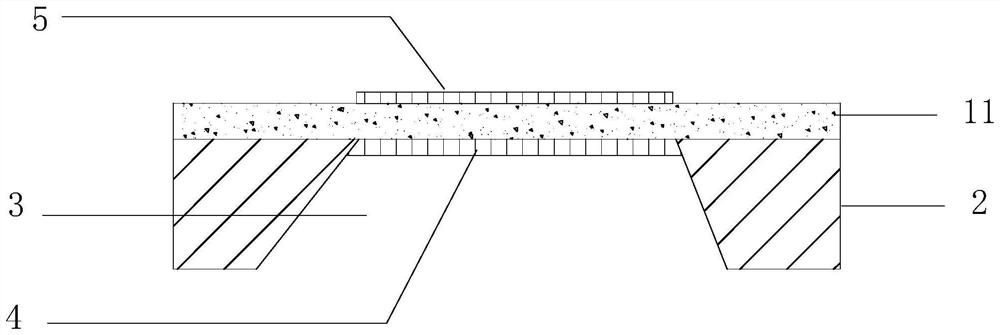

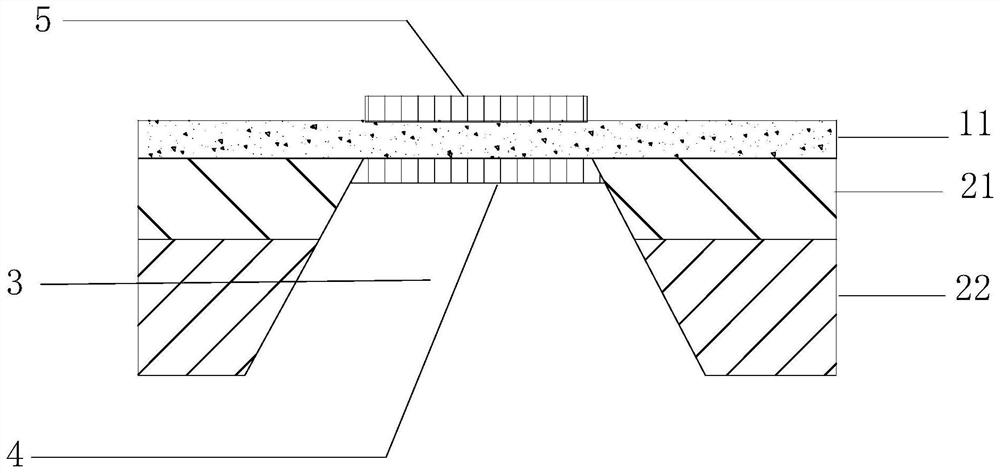

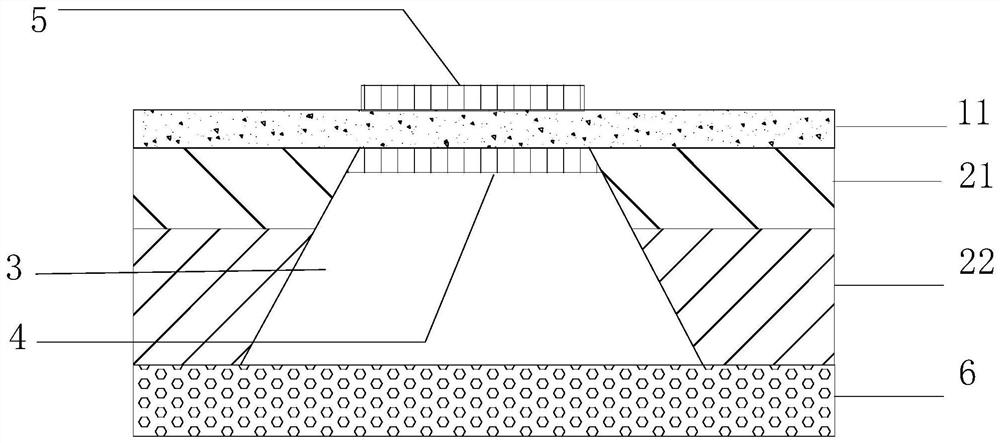

[0060] The embodiment of the present application provides a thin-film bulk acoustic wave device, including a thin-film body with a cavity 3, a top electrode layer 5, and a bottom electrode layer 4; the thin-film body with a cavity 3 includes a first substrate layer 2 and a pressing Electric film layer 11, the cavity 3 runs through the first substrate layer 2; the bottom electrode layer 4 is deposited under the exposed piezoelectric film layer 11 in the cavity 3, and the top electrode layer 5 is deposited on The piezoelectric film layer 11 is opposite to the bottom electrode layer 4 .

[0061] like figure 1 As shown, in the thin film bulk acoustic wave device provided in the embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com