Surface light emitter and production method therefor

A technology of surface luminous body and contact body, which is applied in the field of surface luminous body and its manufacturing, can solve the problems such as difficult to pass through the insulating layer M, easy to accumulate, etc., and achieve the effect of preventing wrinkles and simplifying the manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

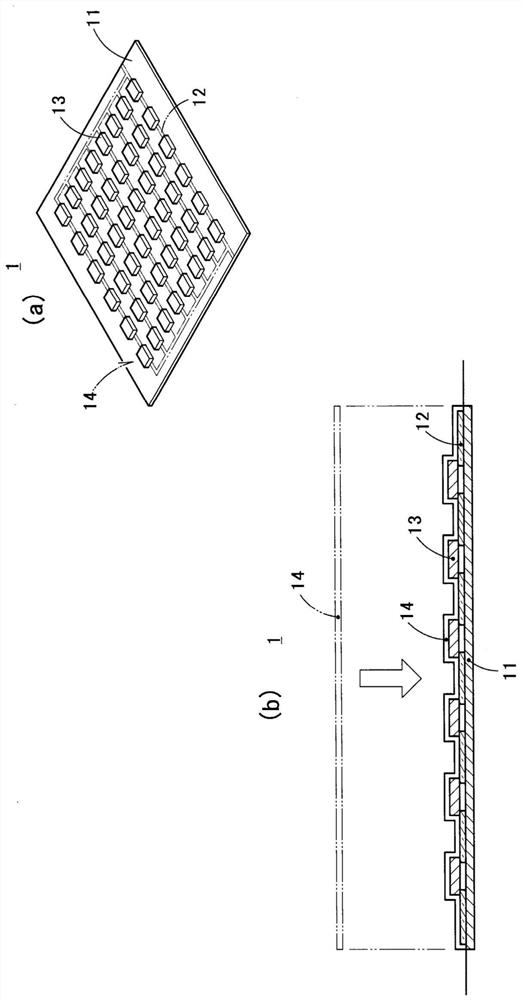

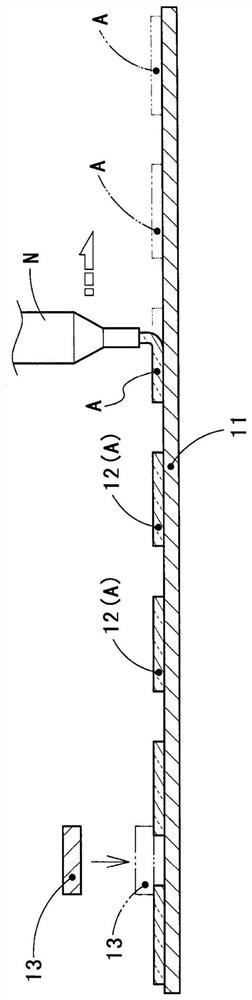

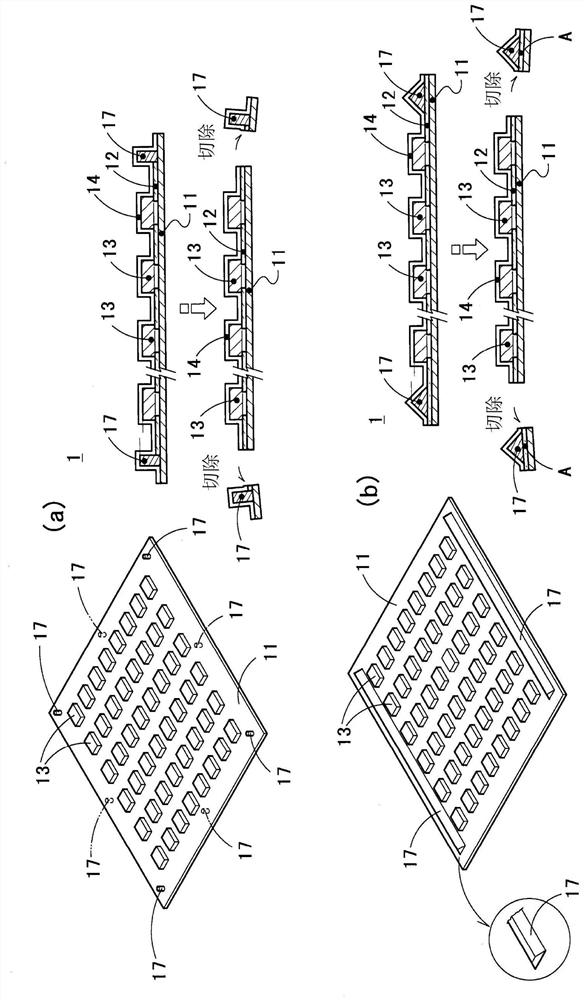

[0046] Surface luminous body 1 of the present invention, one such as figure 1 As shown, it is provided with a bendable substrate 11 having an appropriate circuit pattern (electrical wiring) 12, a plurality of LED elements 13 arranged substantially regularly on the substrate 11, and a substrate for covering the LED elements 13. The top cover 14 disposed on the base material 11 is formed.

[0047] Hereinafter, each member constituting the surface light emitting body 1 will be described.

[0048] First, the substrate 11 will be described.

[0049]The base material 11 is a base member on which the LED elements 13 are regularly arranged (mounted), and is formed, for example, in a film or sheet form, and various materials having insulating properties, flexibility, and the like can be applied. In particular, in the present invention, the base material 11 is formed of an insulating radiation exothermic material (a material that converts heat into far-infrared rays to release heat)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com