Method for predicting service life of lead storage battery

A lead-acid battery and prediction method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of complex battery equivalent models and complex models, and achieve the effect of shortening the test cycle and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Theta value and β-PbO of different types of lead-acid batteries at 0 cycle, 50 cycle and 100 cycle 2 The half-peak width is used for statistics, using theta value and β-PbO 2 The half-peak broadband is entered into the Scherrer formula to calculate the corresponding crystal size, and the results are shown in Table 1.

[0030] Table 1 β-PbO corresponding to different cycles of different types of lead-acid batteries 2 Crystal size and related parameters

[0031]

[0032] At the same time, the β-PbO 2 The crystal parameters and sizes of the experimental data are shown in Table 2.

[0033] Table 2 Corresponding β-PbO when different types of lead-acid batteries fail 2 Crystal size and related parameters

[0034]

[0035]

[0036] As shown in Table 2, it is found from the table that when the lead-acid battery cycle fails, β-PbO 2 The crystal size tends to

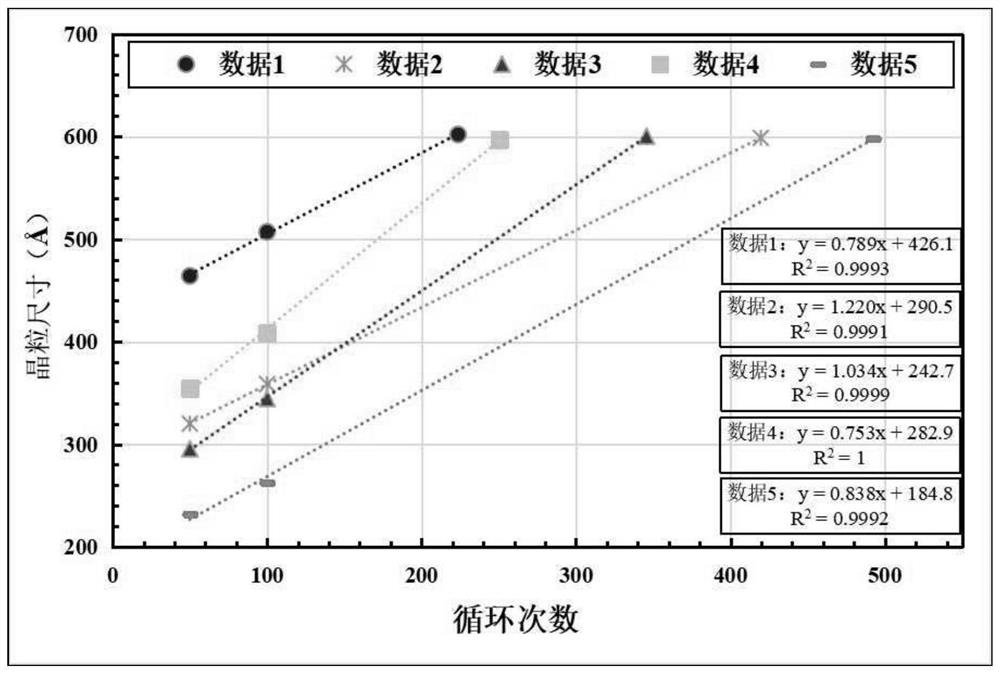

[0037] The corresponding data in Table 1 and Table 2 were curve-fitted and plotted to obtain figure 1...

Embodiment 2

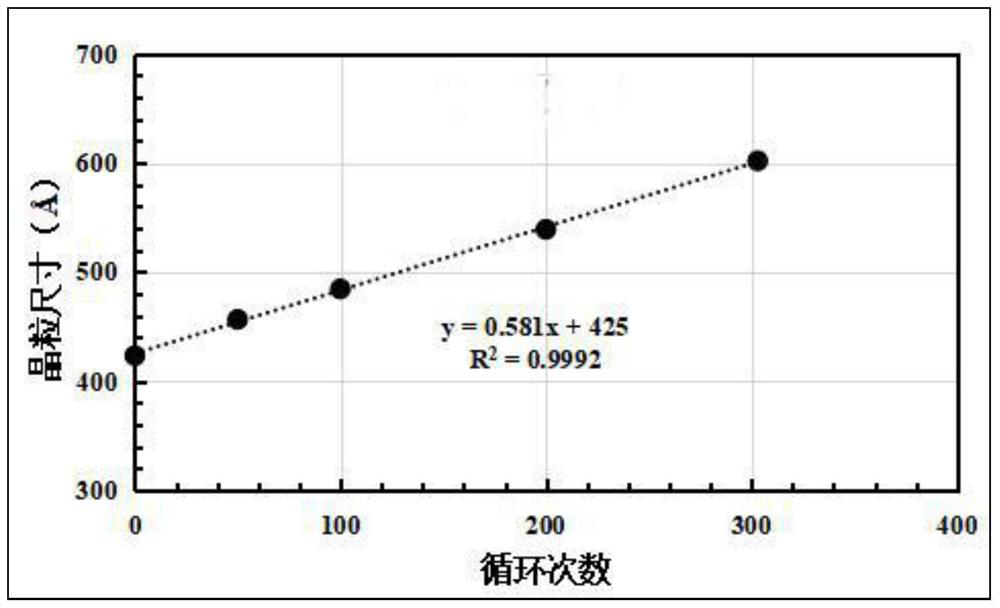

[0040] Take a small-density 20Ah lead-acid battery, dissect it after formation, and get the positive plate; wash the positive plate first and then dry it, take the active material in the middle of the dried positive plate and grind it into powder, and use XRD to test the β-PbO in the active material 2 The half width B of the characteristic peak at θ = 25.4 degrees uses the formula Calculation of β-PbO 2 The crystal size of β-PbO is obtained by taking the half-peak width B of the three characteristic peaks to calculate the crystal size D. 2 The mean value of the crystal size as the corresponding crystal size at 0 cycles.

[0041]Divide small-density 20Ah lead-acid batteries into 4 groups for cyclic charging and discharging. The cyclic charging and discharging process is as follows: first charge at constant voltage 14.7V and limit current at 10A for 4 hours, and then discharge at 10A to 10.2V, which is recorded as a cycle and cycled separately 50 times, 100 times, 200 times...

Embodiment 3

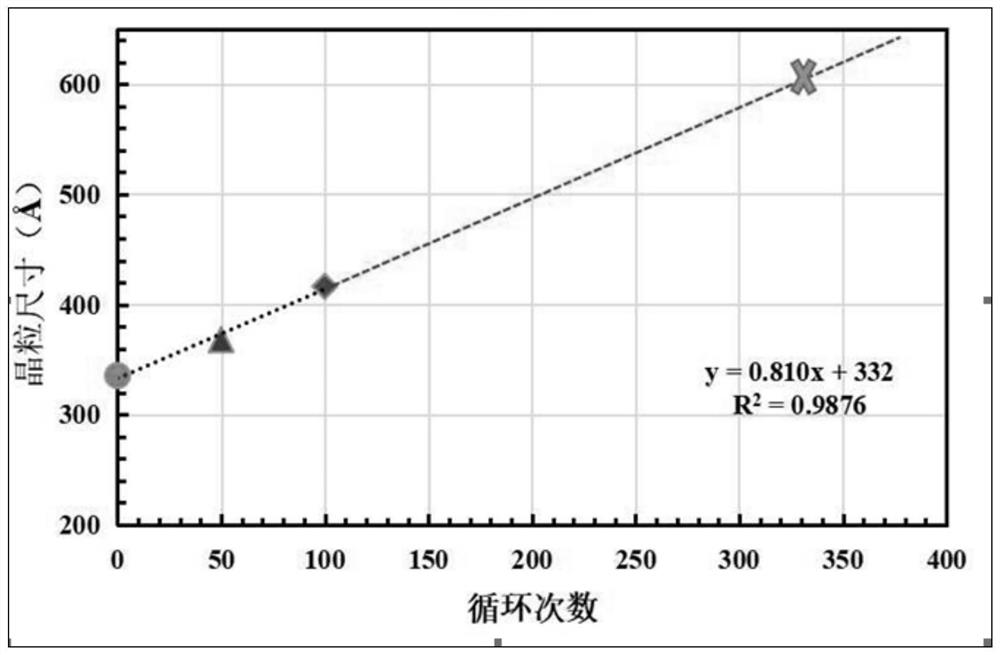

[0050] Based on the mass of lead powder, the density of fiber 0.1%, stannous sulfate 0.1%, antimony trioxide 0.1%, water 10% and 4.5% is 1.4g / cm 3 Sulfuric acid, mixed uniformly and paste, the positive lead paste obtained is coated on the model 6-DZF-20 positive grid, to get the positive plate;

[0051] Based on the mass of lead powder, add 9.5% water and a density of 1.4g / cm 3 4.7% of sulfuric acid, 0.2% of lignin, 0.1% of humic acid, 0.2% of acetylene black, 0.7% of barium sulfate and 0.1% of fiber are mixed evenly, and the paste is carried out, and the negative lead paste obtained is coated on the model 6-DZF -20 On the negative grid, get the negative plate;

[0052] The above-mentioned positive plate and negative plate are assembled into a model of 6-DZF-20 lead storage battery.

[0053] The temperature of the electrolyte is 0℃~10℃, and the density is 1.25g / cm 3 And containing 1% sodium sulfate sulfuric acid solution, after adding 200mL of electrolyte to a single cell, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com