Method for measuring sodium content in slagging agent

A technology of slag removal agent and sodium content, which is applied in the field of chemical detection, can solve the problems of slow reaction speed, low precision, troublesome detection steps, etc., and achieve the effect of fast analysis speed, high precision and wide dynamic linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

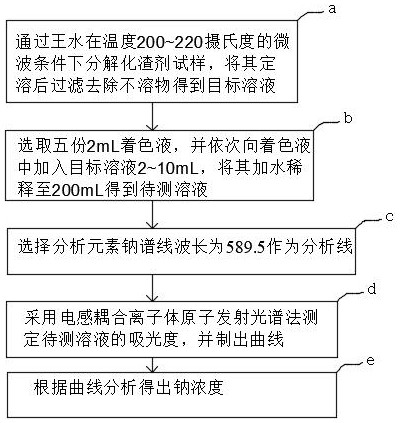

Image

Examples

Embodiment 1

[0024] Weigh 0.1g sample of slag-removing agent in a 250ml beaker, add 20ml aqua regia, and add 0.01mg / mL potassium ion solution (it can avoid the high-concentration example peak covering the low-concentration ion peak and make it undetectable ), shake gently, and put it on a microwave heating device for heating. Compared with traditional heating plate heating, microwave heating has better decomposition ability, thereby improving the uniformity of decomposition and ensuring complete decomposition. The microwave temperature is controlled at 200 degrees Celsius, keep the volume unchanged, after boiling for about 15 minutes, take it out and cool it, dissolve it in a 500ml volumetric flask, shake it well, and filter the test solution into a 100ml volumetric flask with a medium-speed filter paper for later use. for the target solution.

[0025] Select five parts of 2mL coloring solution, and add 2~10mL of the target solution to the coloring solution in turn, dilute it with water to...

Embodiment 2

[0036] Weigh 0.1g sample of slag-removing agent into a 250ml beaker, add 20ml aqua regia, and add 0.01mg / mL potassium ion solution (can avoid high-concentration ion peaks covering low-concentration ion peaks and make them undetectable ), shake gently, and put it on a microwave heating device for heating. Compared with traditional heating plate heating, microwave heating has better decomposition ability, thereby improving the uniformity of decomposition and ensuring complete decomposition. The microwave temperature is controlled at 220 degrees Celsius, keep the volume constant, after boiling for about 15 minutes, take it off and cool it, dissolve it in a 500ml volumetric flask, shake it well, and filter the test solution into a 100ml volumetric flask with a medium-speed filter paper for later use. for the target solution.

[0037] Select five parts of 2mL coloring solution, and add 2~10mL of the target solution to the coloring solution in turn, dilute it with water to 200mL to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com