Method for recovering germanium from copper-lead-zinc-arsenic-germanium materials

A material, copper and lead technology, applied in the field of germanium recovery, can solve the problems of arsenic hydrogen gas hazards, poisoning accidents, etc., and achieve the effect of less production pollution and reduced hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

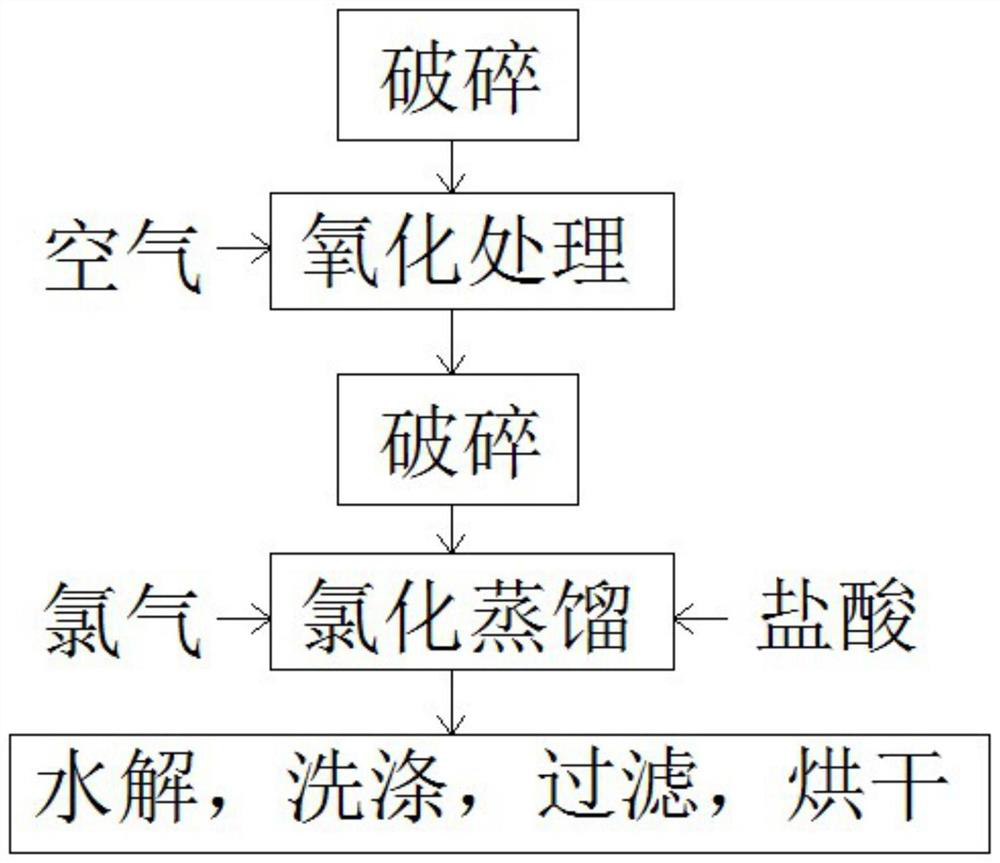

[0022] Such as figure 1 Shown, the method that reclaims germanium from copper-lead-zinc-arsenic-germanium material:

[0023] In the first step, the copper, lead, zinc, arsenic and germanium materials are crushed to 120 meshes, and then an oxidant is added. The weight of the oxidant is 8% of the weight of the material, and the mixture is uniformly obtained by mixing;

[0024] In the second step, the mixture obtained in the first step is oxidized, oxidized at a low temperature of 300°C for 2 hours, then raised to 400°C for 2 hours, then raised to 600°C for 2 hours, then raised to 750°C for 2 hours Cooling out of the furnace to obtain metal oxides;

[0025] In the third step, the metal oxide obtained in the third step is crushed to 120 mesh;

[0026] The fourth step is to mix the crushed metal oxide with hydrochloric acid, chlorinated distillation, the solid-to-liquid mass ratio of metal oxide and hydrochloric acid is 1:12, pass chlorine gas for about 2 hours during chlorinated...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is that in the first step, the weight of the oxidant is 5% of the material weight, and the effective recovery rate of germanium is 96.88%.

Embodiment 3

[0031] The difference between this embodiment and embodiment 1 is that in the first step, the weight of the oxidant is 10% of the material weight, and the effective recovery rate of germanium is 97.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com