A kind of high thermal conductivity polyimide film and its production process

A polyimide film and production process technology, applied in the field of high thermal conductivity polyimide film and its production process, can solve the problems of dark color, tear resistance and little improvement in thermal conductivity, etc. Spectral properties, weakening the effect of CTC, and improving the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of diamine monomers:

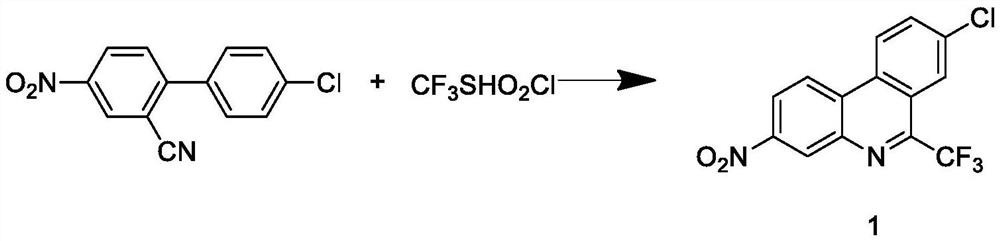

[0045] Step S1, under the protection of argon, add 4'-chloro-4-nitro-[1,1'-biphenyl]-2-carbonitrile, K 2 HPO 4, N,N-dimethylacetamide, cooled to 0°C, added trifluoromethanesulfonyl chloride, reacted with light source for 7h, added deionized water, extracted twice with ethyl acetate, combined the organic phases and washed with saturated brine , and then dried with anhydrous magnesium sulfate, and the solvent was removed by rotary evaporation to obtain intermediate 1, in which 4'-chloro-4-nitro-[1,1'-biphenyl]-2-carbonitrile, K 2 HPO 4 , The molar ratio of N,N-dimethylacetamide and trifluoromethanesulfonyl chloride is 1:3:50:1, and the wavelength of the light source is 280nm;

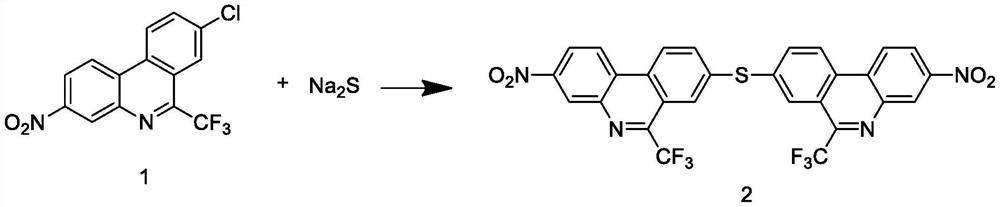

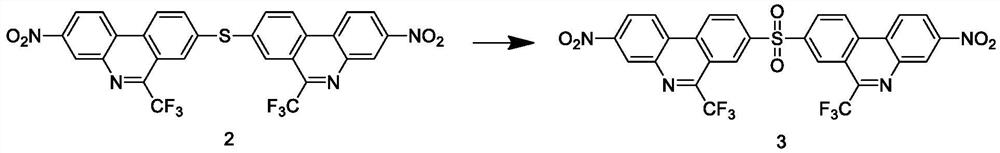

[0046] Step S2, add 0.9 mol of intermediate 1, 0.45 mol of sodium sulfide nonahydrate, and 410 mL of N,N-dimethylacetamide into a three-necked flask, and under nitrogen protection, heat up to 170°C for 24 hours, filter, and wash the filter cake with water , dr...

Embodiment 2

[0050] Preparation of diamine monomers:

[0051] Step S1, under the protection of argon, add 4'-chloro-4-nitro-[1,1'-biphenyl]-2-carbonitrile, K 2 HPO 4 , N, N-dimethylacetamide, cooled to 0°C, added trifluoromethanesulfonyl chloride, reacted with light source for 7 hours, added deionized water, extracted twice with ethyl acetate, combined the organic phases and washed with saturated brine , and then dried with anhydrous magnesium sulfate, and the solvent was removed by rotary evaporation to obtain intermediate 1, in which 4'-chloro-4-nitro-[1,1'-biphenyl]-2-carbonitrile, K 2 HPO 4 , The molar ratio of N,N-dimethylacetamide and trifluoromethanesulfonyl chloride is 1:3:50:1, and the wavelength of the light source is 350nm;

[0052] Step S2, add 0.91 mol of intermediate 1, 0.45 mol of sodium sulfide nonahydrate, and 420 mL of N,N-dimethylacetamide into a three-necked flask, and under nitrogen protection, heat up to 170°C for 24 hours, filter, and wash the filter cake with wat...

Embodiment 3

[0056] Preparation of diamine monomers:

[0057] Step S1, under the protection of argon, add 4'-chloro-4-nitro-[1,1'-biphenyl]-2-carbonitrile, K 2 HPO 4 , N,N-dimethylacetamide, cooled to 0°C, added trifluoromethanesulfonyl chloride, reacted with light source for 8h, added deionized water, extracted 4 times with ethyl acetate, combined the organic phases and washed with saturated brine , and then dried with anhydrous magnesium sulfate, and the solvent was removed by rotary evaporation to obtain intermediate 1, in which 4'-chloro-4-nitro-[1,1'-biphenyl]-2-carbonitrile, K 2 HPO 4 , The molar ratio of N,N-dimethylacetamide and trifluoromethanesulfonyl chloride is 1:3:50:1, and the wavelength of the light source is 780nm;

[0058] Step S2, add 0.92 mol of intermediate 1, 0.46 mol of sodium sulfide nonahydrate, and 430 mL of N,N-dimethylacetamide into a three-necked flask, and under nitrogen protection, heat up to 170°C for 24 hours, filter, and wash the filter cake with water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com