Nitrile rubber material with low pressure change in IRM903 oil and preparation method thereof

A rubber material and nitrile-varying technology, which is applied in the field of IRM903 oil medium and low-pressure nitrile-butadiene rubber material and its preparation, can solve problems such as insufficiency, and achieve the effects of reducing swelling, good compression resilience, and good compression set performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

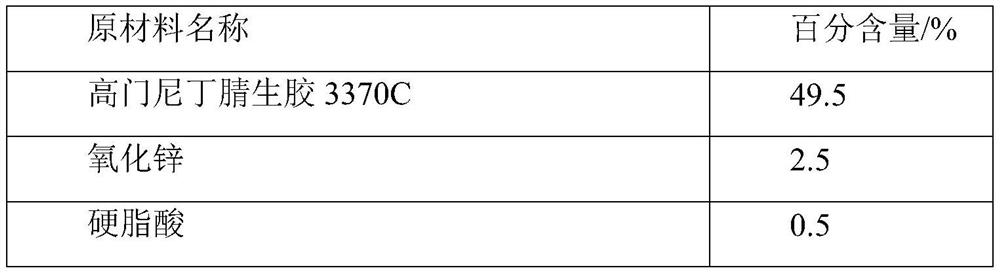

Embodiment 1

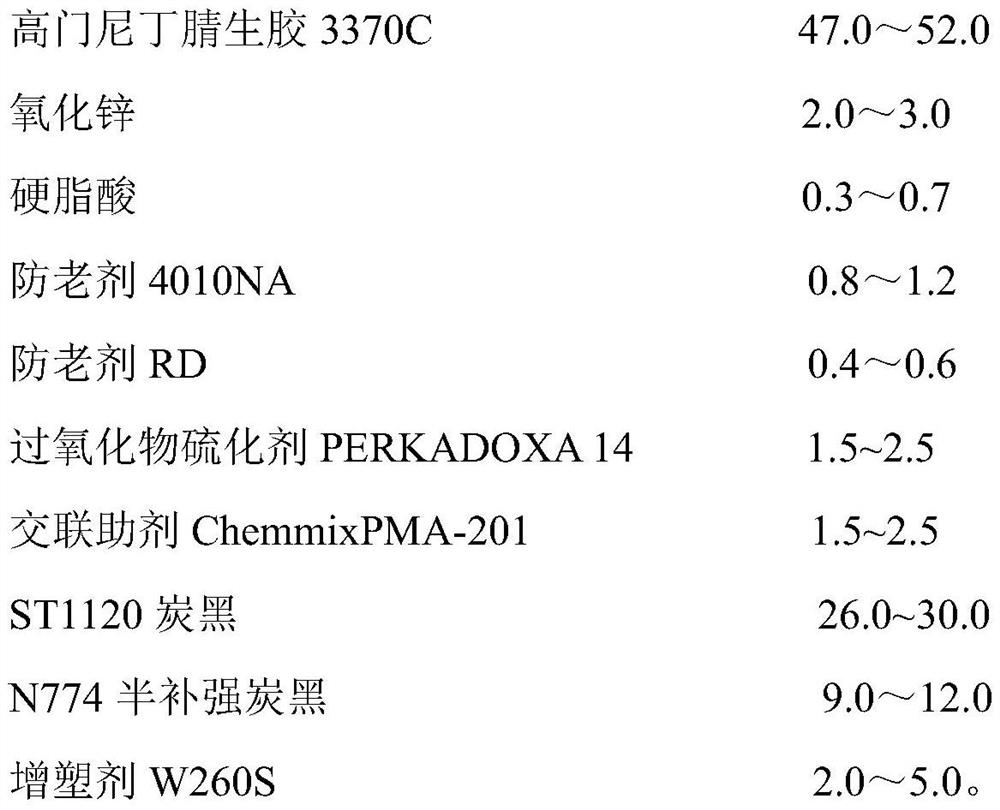

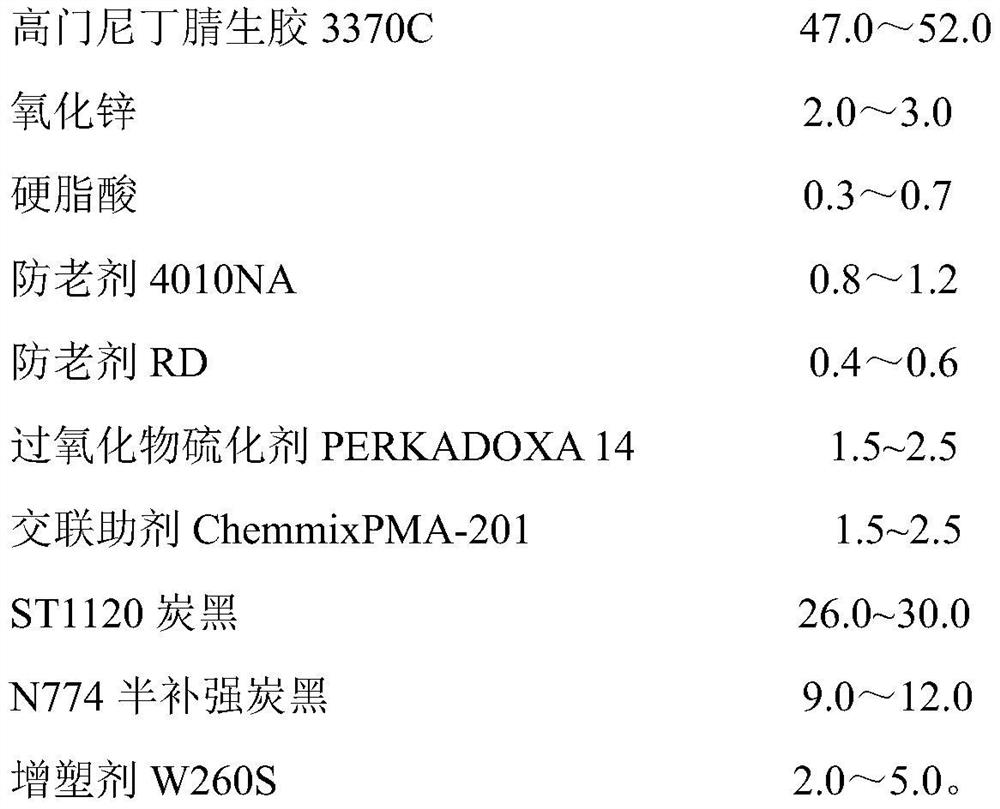

[0026] A kind of IRM903 oil medium and low pressure variable nitrile rubber material of the present embodiment, comprises the component of following percentage by weight:

[0027] Component and percentage content of low-pressure variable nitrile rubber material in table 1 embodiment 1 IRM903 oil

[0028]

[0029]

[0030] Specifically, in this example, the raw high-mened nitrile rubber 3370C in this implementation is produced by Arlanxeo High Performance Elastomers (Changzhou) Co., Ltd. As an implementation, the Mooney viscosity ML(1+4) of the high Mooney nitrile raw rubber 3370C in this example is 100°C: 70. Preferably, the percentage by weight of the raw high Menedene nitrile rubber 3370C in this embodiment is 49.5%. In this example, high Mooney nitrile raw rubber 3370C is used in the formula, and the Mooney viscosity ML(1+4) of the raw rubber is 100°C: 70. Compared with the conventional Mooney viscosity nitrile raw rubber, its compression set performance is better i...

Embodiment 2

[0068] A kind of IRM903 oil medium and low pressure variable nitrile rubber material of the present embodiment, comprises the component of following percentage by weight:

[0069] Component and percentage content of low-pressure variable nitrile rubber material in table 6 embodiment 2 IRM903 oil

[0070] Raw material name Percent content / % High door Nitrile Raw Rubber 3370C 47.0 Zinc oxide 3.0 stearic acid 0.7 Antiaging agent 4010NA 1.2 Antiaging agent RD 0.6 Peroxide curing agent PERKADOXA 14 2.5 Crosslinking Auxiliary ChemmixPMA-201 2.0 ST1120 carbon black 30.0 N774 semi-reinforcing carbon black 9.0 Plasticizer W260S 4.0

[0071] A kind of preparation method of IRM903 oil middle and low pressure variable nitrile rubber material of the present invention, its step is:

[0072] (1) Masterbatch mixing:

[0073] According to the above formula, add all the components in Table 6 except peroxide vulcanizing ...

Embodiment 3

[0080] A kind of IRM903 oil medium and low pressure variable nitrile rubber material of the present embodiment, comprises the component of following percentage by weight:

[0081] Components and percentage content of low-pressure variable nitrile rubber material in table 7 embodiment 3IRM903 oil

[0082] Raw material name Percent content / % High door Nitrile Raw Rubber 3370C 52.0 Zinc oxide 2.0 stearic acid 0.3 Antiaging agent 4010NA 0.8 Antiaging agent RD 0.4 Peroxide curing agent PERKADOXA 14 1.5 Crosslinking Auxiliary ChemmixPMA-201 1.5 ST1120 carbon black 27.0 N774 semi-reinforcing carbon black 12.0 Plasticizer W260S 2.5

[0083] A kind of preparation method of IRM903 oil middle and low pressure variable nitrile rubber material of the present invention, its step is:

[0084] (1) Masterbatch mixing:

[0085] According to the formula described in claim 1, all components except peroxide vulcanizing age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com