Preparation method of praseodymium oxide particle modified lithium ion battery positive electrode material

A lithium-ion battery and positive electrode material technology, applied in the field of preparation of lithium-ion battery positive electrode materials, can solve the problems of high energy consumption, little help in commercial practical application, low working voltage range, etc., and achieve the purpose of prolonging the high-voltage cycle life and battery life. Chemical properties, the effect of alleviating the dissolution of transition metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

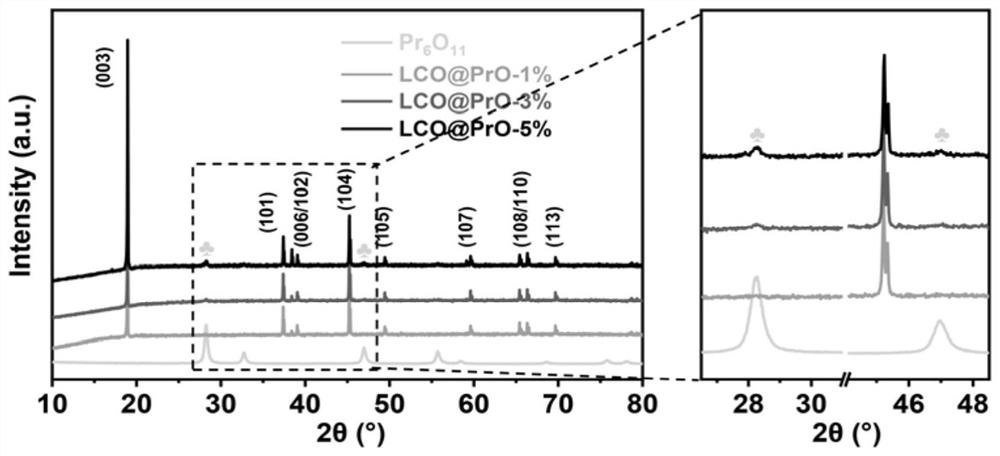

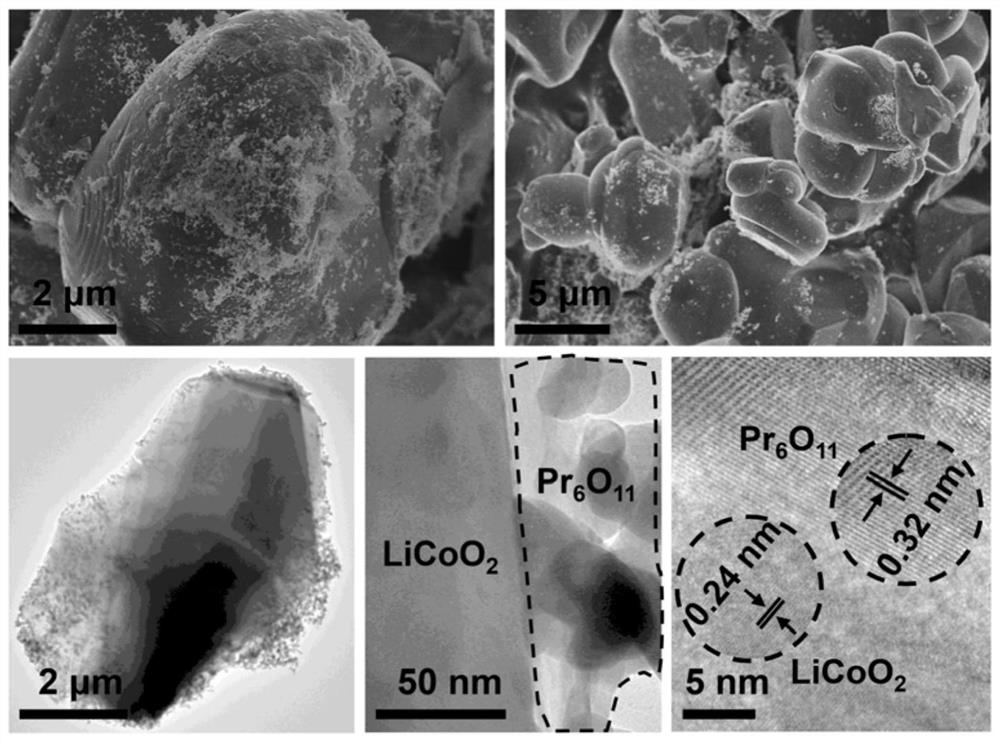

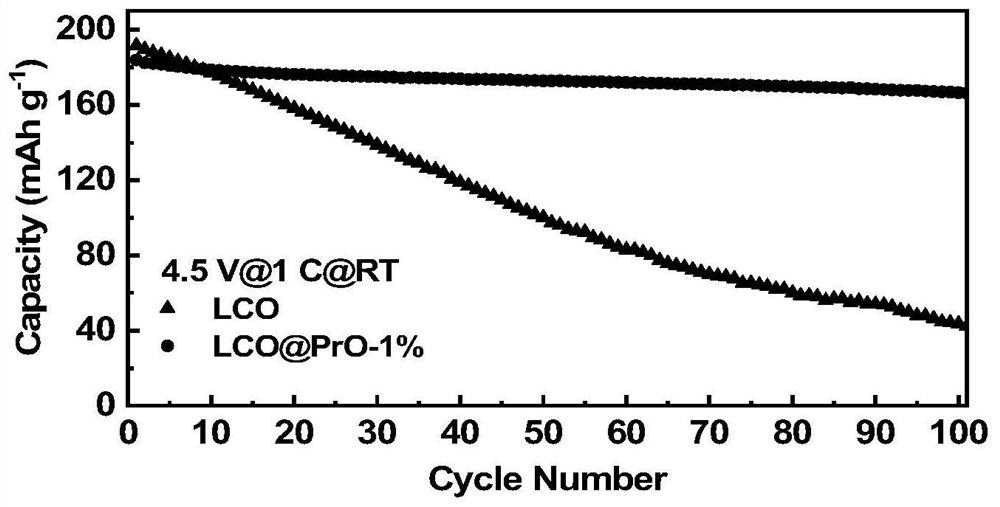

[0029] A preparation method of a lithium-ion battery cathode material modified by praseodymium oxide particles, comprising the following steps:

[0030] 1) A certain amount of praseodymium nitrate (Pr(NO 3 ) 3 ·6H 2 O) dispersed in deionized water, configured to a concentration of 0.002-0.01mol L -1 Praseodymium nitrate solution;

[0031] 2) Weigh a certain amount of LiCoO 2 Add the positive electrode material into deionized water, stir vigorously, and then ultrasonicate for 40-60min under the condition of ultrasonic power of 500-1000 W, then add the praseodymium nitrate solution prepared in step 1) dropwise, stir vigorously and ultrasonically treat for 40-60min, ultrasonically The power is 500-1000W, and the positive electrode material mixture containing praseodymium nitrate is obtained;

[0032] 3) Add ammonia water (NH 3 ·H 2 0), the pH of the mixed solution is adjusted to PH=11, while vigorously stirring for 4-4.5h;

[0033] 4) The mixed solution is subjected to ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com