Ag-AgX nanowire and preparation method thereof

A nanowire, ag-agx technology, applied in the field of Ag-AgX nanowire and its preparation, can solve the problems of high cost and complex preparation process, and achieve the effects of uniform size, simple operation process and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing Ag / AgX nanowires with uniform size. Water is used as a solvent, and a soluble silver source is used as a silver source. Ag / AgX (X=Cl, Br, I) nanowires or nanorods with uniform size. The preparation method comprises the following steps:

[0034] (1) The soluble silver source (silver nitrate or silver acetate) with a molar ratio of 1:2~10:0.05~0.6 (preferably 1:3~5:0.12~0.28) and surfactant A and surfactant B ( or halide salt) in water, stirred evenly, and the total molar concentration of the three raw materials and the mixed solution after uniform mixing was controlled within the range of 0.03-0.12mol / L, and then heated at a reaction temperature of 180-220°C, Reacting for 5-20 hours; (2) The feed liquid obtained by the reaction is centrifuged and washed to obtain Ag / AgX nanowires or nanorods with uniform size.

[0035]Wherein, surfactant A is selected from any one of polyvinylpyrrolidone, N-methylpyrrolidone, vinylpyrrolido...

Embodiment 1

[0037] Weigh 0.034g AgNO 3 , 0.1g PVP and 0.02g CTAB were dissolved in 20mL water, and the solution was stirred evenly; the obtained solution was transferred to a 50mL reactor, heated in an oven at 200°C, and reacted for 10h to obtain the reaction product;

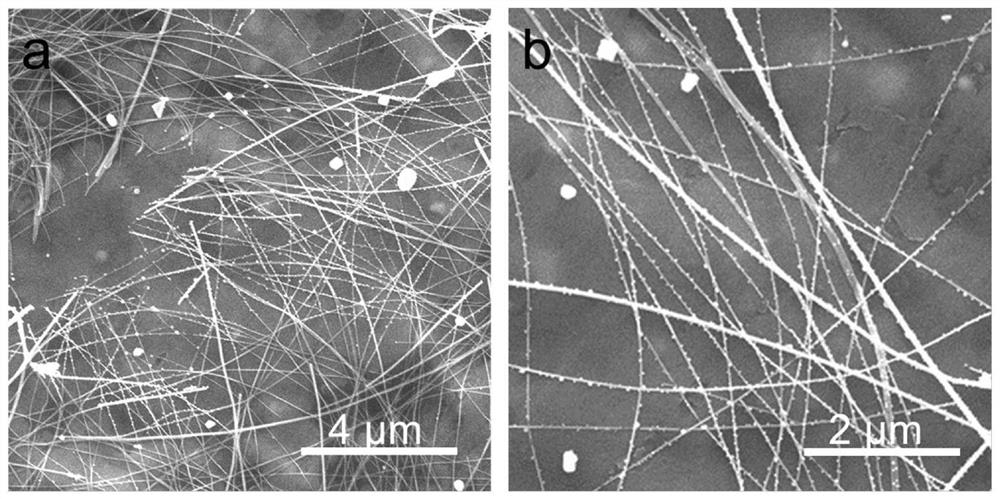

[0038] The prepared reaction product is carried out centrifugal washing, obtains Ag-AgBr sample (such as figure 1 as shown, figure 1 a is the SED image of the sample at low magnification, figure 1 b is a high magnification SEM image of the sample), which is a uniform size one-dimensional nanowire with a diameter of about 30nm and a length greater than 40μm, and its structural components are as follows figure 2 shown.

Embodiment 2

[0040] Weigh 0.034gAgNO 3 , 0.1g PVP and 0.02g CTAB were dissolved in 20mL water, and the solution was stirred evenly; the obtained solution was transferred to a 50mL reactor, heated in an oven at 200°C, and reacted for 5h to obtain the reaction product;

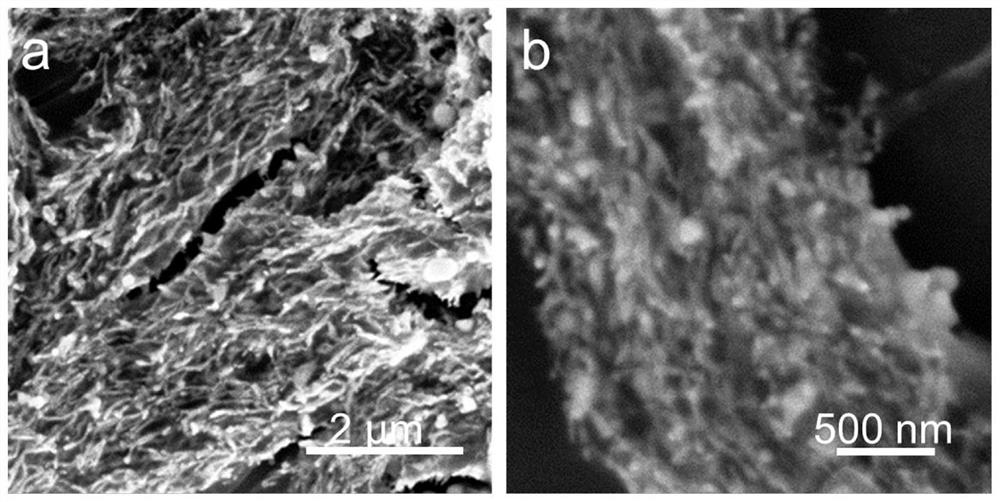

[0041] The prepared reaction product is carried out centrifugal washing, obtains Ag-AgBr sample (such as image 3 As shown), it is a one-dimensional nanowire with a diameter of about 30 nm and a length of tens of microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com