Manufacturing method of stamping formed part, and stamping formed part

A technology of stamping forming and manufacturing method, which is applied in the field of stamping and forming parts and stamping-forming parts manufacturing, can solve the problems of reducing the manufacturing efficiency of stamping and forming parts, save the operation of hole flanging and shaping, reduce the difference of force, and enhance the The effect of suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

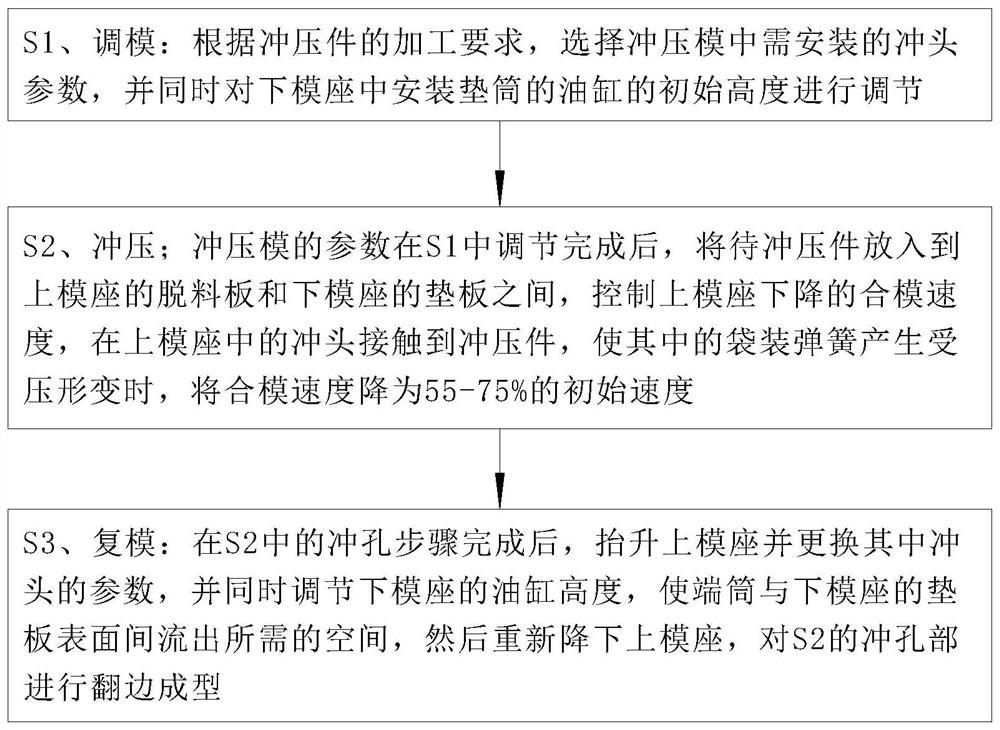

Method used

Image

Examples

Embodiment approach

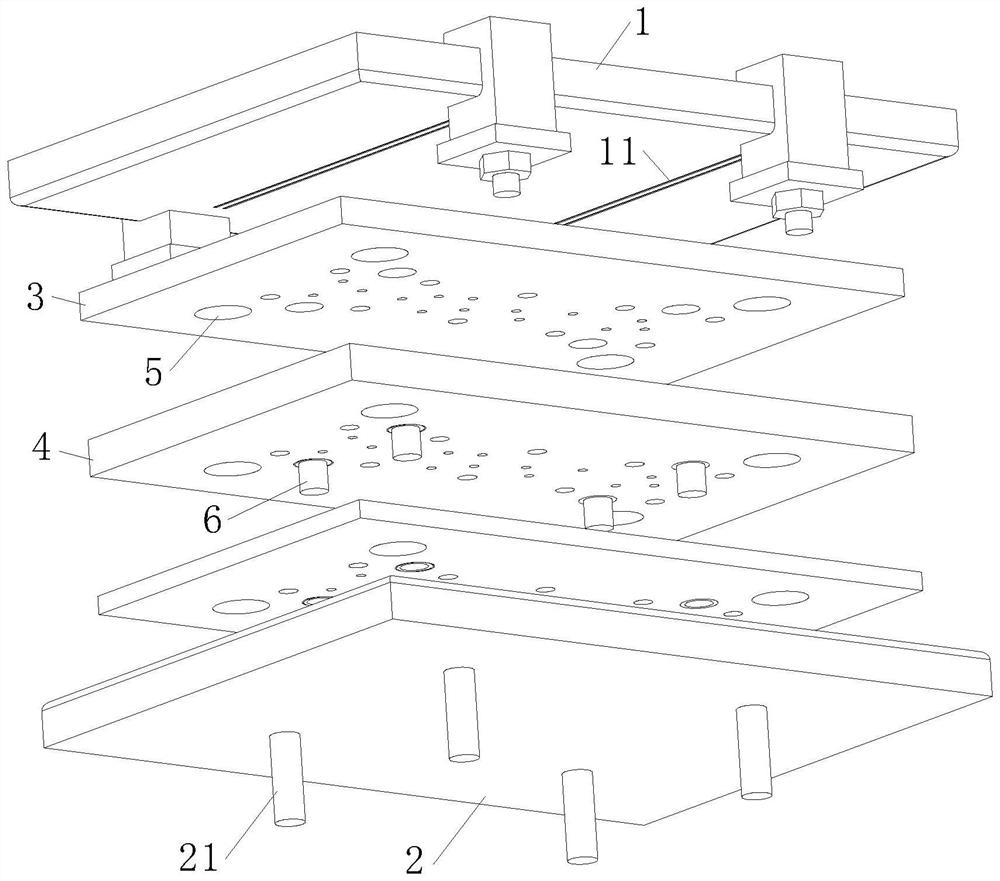

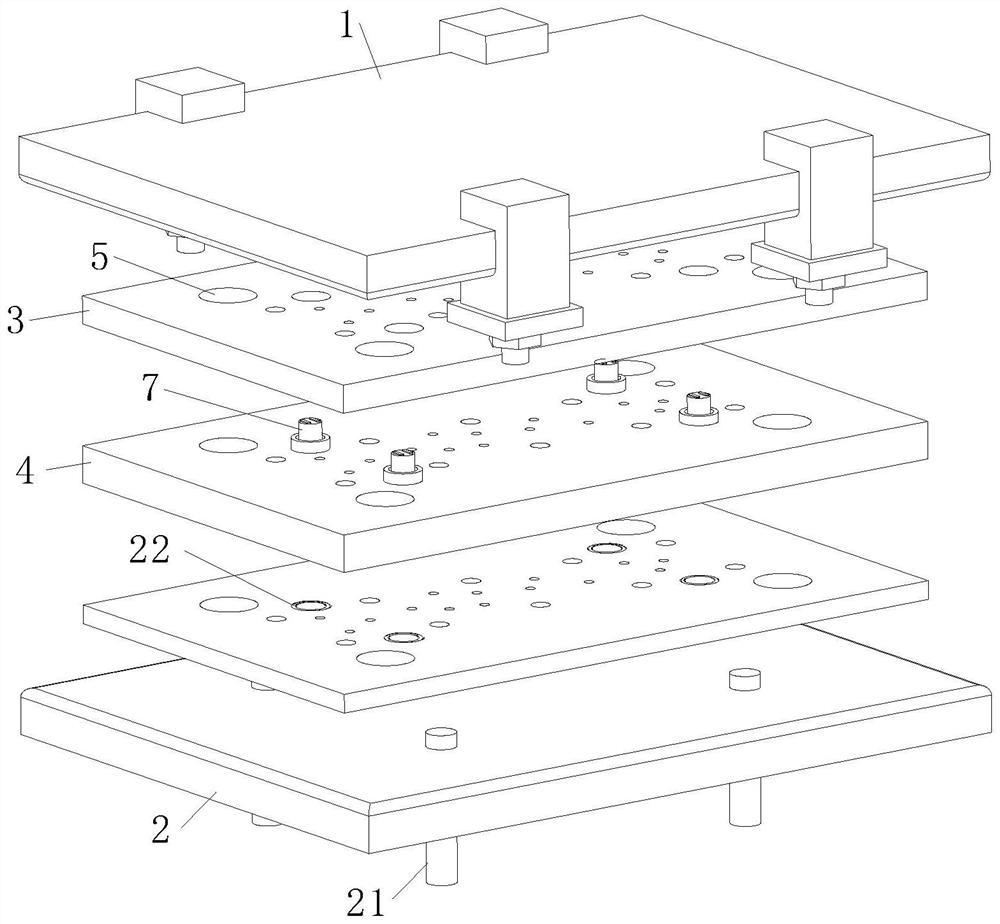

[0038] As an embodiment of the present invention, a pair of electromagnets 72 magnetically repelling each other are fixedly connected to both ends of the pocket spring 7 , and a pair of electrode pieces are fixedly connected to the electromagnet 72 at the end of the pocket spring 7 toward the upper mold base 1 721, the electrode sheet 721 protrudes from the surface of the pocket spring 7; the surface of the upper mold base 1 is provided with an electrode groove 11, and the electrode groove 11 is in electrical contact with the electrode sheet 721; during the manufacturing process of the stamped part, By setting the electromagnets 72 at both ends of the pocket spring 7 to magnetically repel each other, by controlling the magnitude of the connected current, the parameters of different stamping pressures are satisfied, and at the same time, the pocket spring 7 with a relatively large deformation is contracted in the positioning hole 5, The distance between the electromagnets 72 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com