Modified NCMA quaternary positive electrode material and preparation method thereof

A cathode material and modification technology, which is applied in the field of modified NCMA quaternary cathode materials and its preparation, can solve the problems of many times of mixing, small amount of potting, and low efficiency of sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

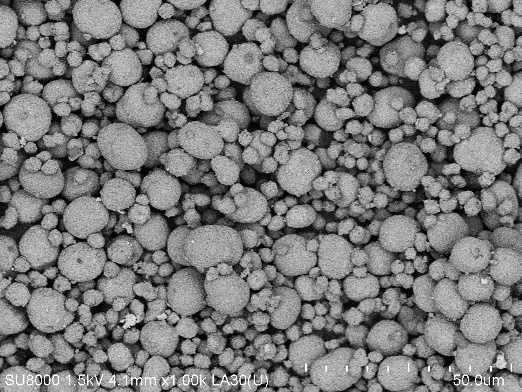

Image

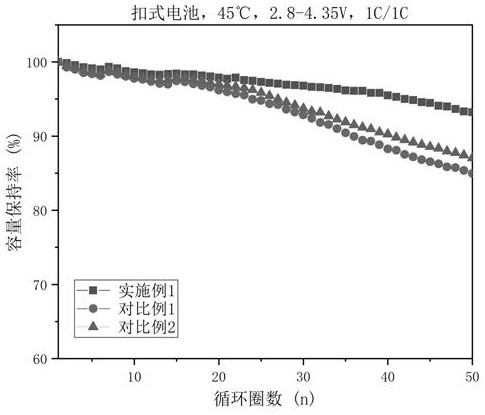

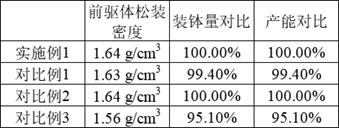

Examples

Embodiment 1

[0037] Preparation of NCMA quaternary cathode material:

[0038] Step 1, high-nickel polycrystalline Ni with Dv50 of 11.5 μm 0.90 co 0.05 mn 0.04 Al 0.01 (OH) 2 Precursor, ethyl orthosilicate Si(OC 2 h 5 ) 4 Mix according to the molar ratio of 1.0:0.03, add to the mixed solution of absolute ethanol and deionized water to dissolve, and obtain the mixed solution A. The mass ratio of deionized water to precursor is 2:5; the volume ratio of deionized water to ethanol is 2:50.

[0039] Step 2, the mixture A was stirred at 50 °C for 5 h, and then continued to stir at 80 °C until the solution was completely evaporated to obtain large particles of Ni 0.90 co 0.05 mn 0.04 Al 0.01 (OH) 2 @SiO 2 Precursor, coded as Lp.

[0040] Step 3, high-nickel polycrystalline Ni with Dv50 of 3.5 μm 0.90 co 0.05 mn 0.04 Al 0.01 (OH) 2 The precursor was added to deionized water to prepare slurry B, the weight ratio of precursor to deionized water was 1:5; 2 mol / L Na 2 S 2 o 8 The ...

Embodiment 2

[0072] High-nickel polycrystalline Ni with a Dv50 of 14 μm 0.92 co 0.05 mn 0.02 Al 0.01 (OH) 2 Precursor, ethyl orthosilicate Si(OC 2 h 5 ) 4 Mix according to the molar ratio of 1.0:0.03, add to the mixed solution of absolute ethanol and deionized water to dissolve, and obtain the mixed solution A. The mass ratio of deionized water to precursor is 2:5; the volume ratio of deionized water to ethanol is 2:50.

[0073] The mixture A was stirred at 50 °C for 5 h, and then continued to stir at 80 °C until the solution was completely evaporated to obtain large particles of Ni 0.92 co 0.05 mn 0.02 Al 0.01 (OH) 2 @SiO 2 Precursor, coded as Lp.

[0074] High nickel polycrystalline Ni with a Dv50 of 3.5 μm 0.88 co 0.06 mn 0.05 Al 0.01 (OH) 2 The precursor was added to deionized water to prepare slurry B, the weight ratio of precursor to deionized water was 1:5; 2 mol / L Na 2 S 2 o 8 The solution and 4mol / L NaOH solution are configured in a volume ratio of 1:1 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com