Production process and system of high-precision lithium battery pole piece

A production process and production system technology, applied in the production process and system field of high-precision lithium battery pole pieces, can solve the problems of pole piece rebound, inconsistent compaction density, coating process influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

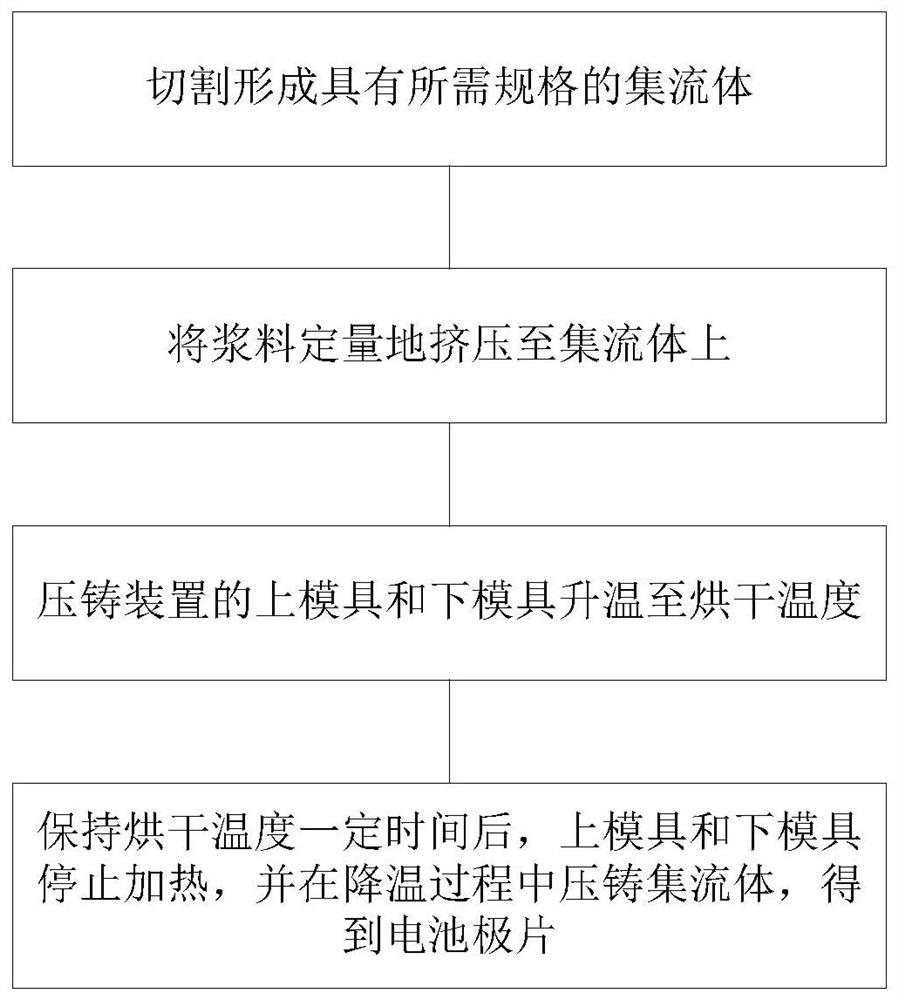

[0053] Such as figure 1 The production process of a high-precision lithium battery pole piece shown includes the following steps:

[0054] (A) cutting to form current collectors with desired specifications;

[0055] (B) Put the current collector into the lower mold of the die-casting device, and quantitatively squeeze the slurry onto the current collector;

[0056] (C) The upper mold and the lower mold of the die-casting device are heated to the drying temperature;

[0057] (D) After maintaining the drying temperature for a certain period of time, stop heating the upper mold and the lower mold, and die-cast the current collector during the cooling process to obtain the battery pole piece.

[0058] In one or more embodiments, ultrasonic vibrating is used to quickly and evenly spread the slurry over the current collector.

[0059] In some embodiments, the drying temperature is 140-160°C.

[0060] In some embodiments, the compacted density of the obtained battery electrode sh...

Embodiment 2

[0063] On the basis of Example 1, in the step (B), after the slurry is extruded onto the current collector, the temperature of the lower mold is raised to the first temperature, and the first temperature is 80-95°C; the slurry After being extruded onto the current collector, the lower mold is raised to the first temperature to preheat the slurry, so as to avoid the occurrence of defects caused by excessive drying after the slurry quickly enters the constant-speed drying stage. In the step (D), the upper mold moves downward from the initial position to the pre-compression position, and when the temperature drops to the second temperature, the upper mold moves downward from the pre-compression position to the final die-casting position. The second temperature is 90-125°C.

[0064] During the cooling process, the moisture diffusion rate inside the slurry in the early stage of cooling is lower than the vaporization rate of the surface moisture at the wet bulb temperature. At this ...

Embodiment 3

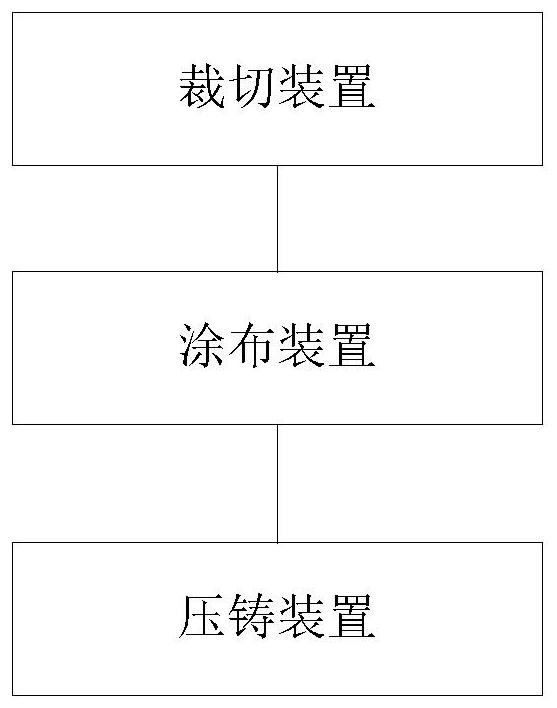

[0068] Such as Figure 2 to Figure 5 A production system for high-precision lithium battery pole pieces is shown, the system includes a cutting device, a coating device and a die-casting device, wherein:

[0069] The cutting device is used to cut copper foil or aluminum foil into current collectors 1 with required specifications by laser processing;

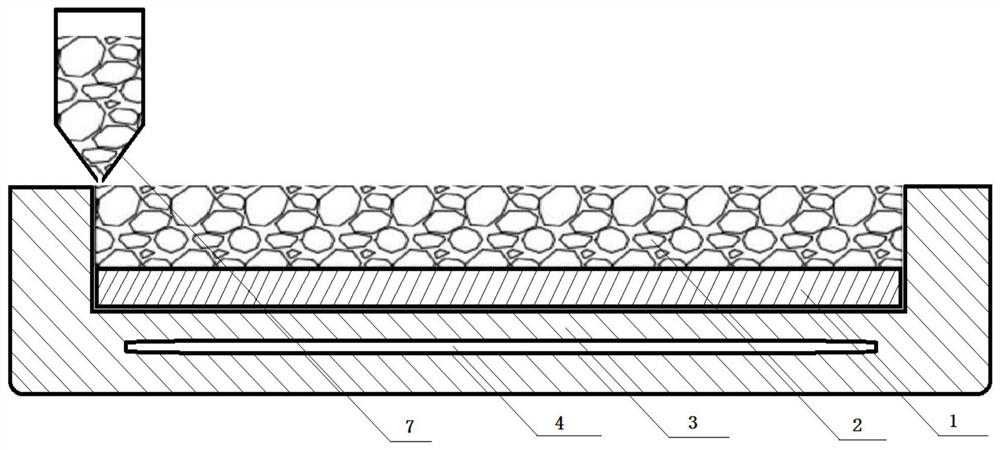

[0070] The coating device is used to quantitatively squeeze the slurry into the lower mold 3 of the die-casting device, and the slurry 2 is spread above the current collector 1;

[0071] The die-casting device also includes an upper mold 6, the upper mold 6 squeezes the slurry and the current collector 1 in the lower mold 3, and die-casts to obtain battery pole pieces.

[0072] In this embodiment, the cutting device, the coating device and the die-casting device complete the cutting, coating and die-casting processes continuously.

[0073] In one or more embodiments, ultrasonic vibrating is used to quickly and evenly spread the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com