A die-casting system and die-casting process for lithium battery pole piece mold forming

A mold forming and lithium battery technology, applied in electrode forming, battery electrodes, electrode manufacturing, etc., can solve the problems of pole piece rebound and inconsistent ductility, so as to prevent rebound, improve die-casting effect and quality, and prevent pole piece rebound Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

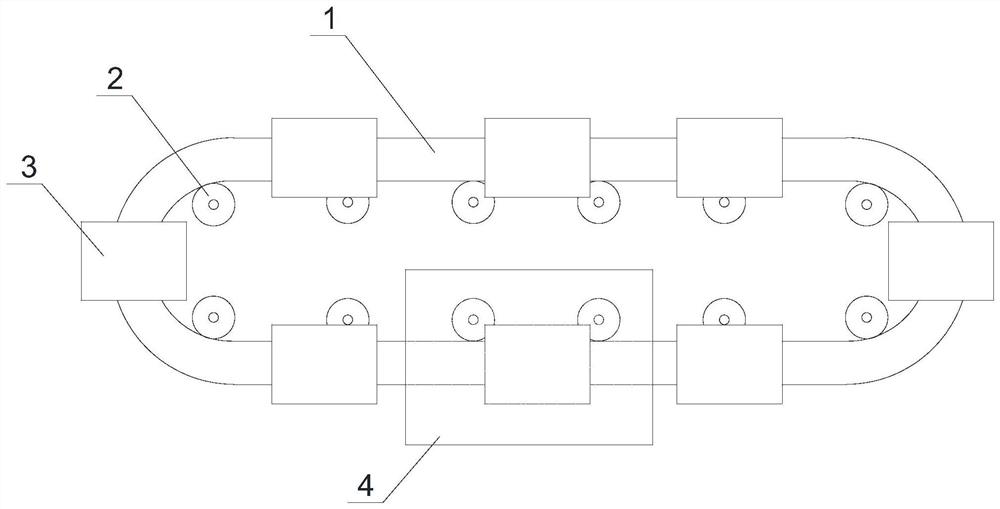

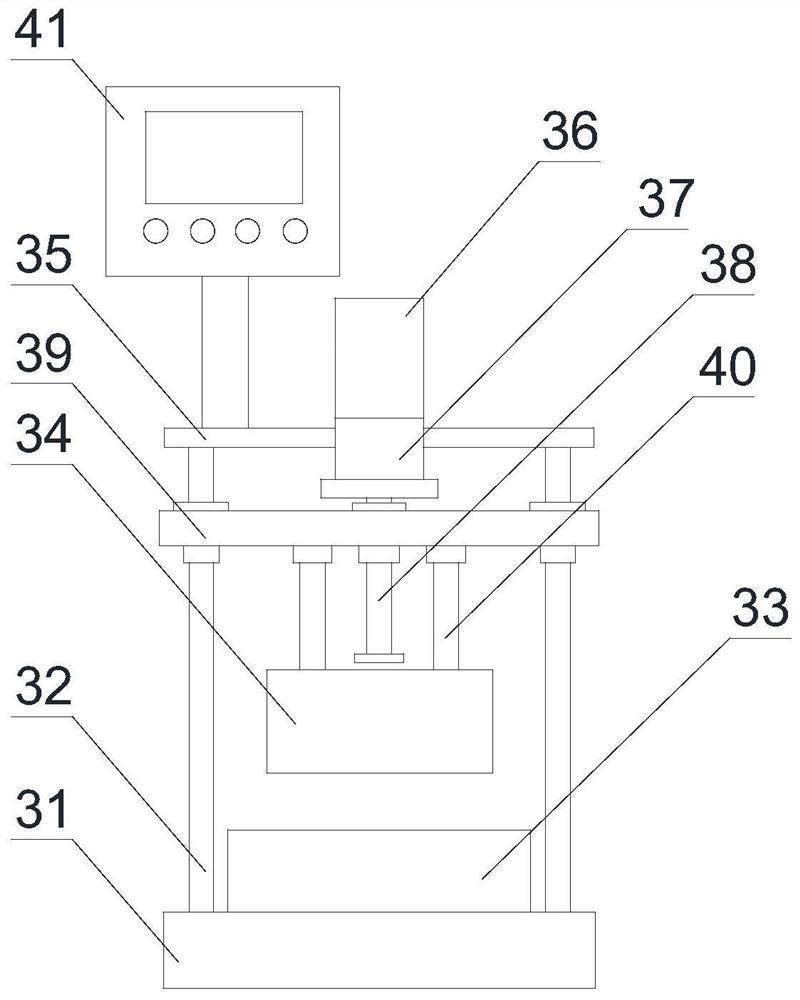

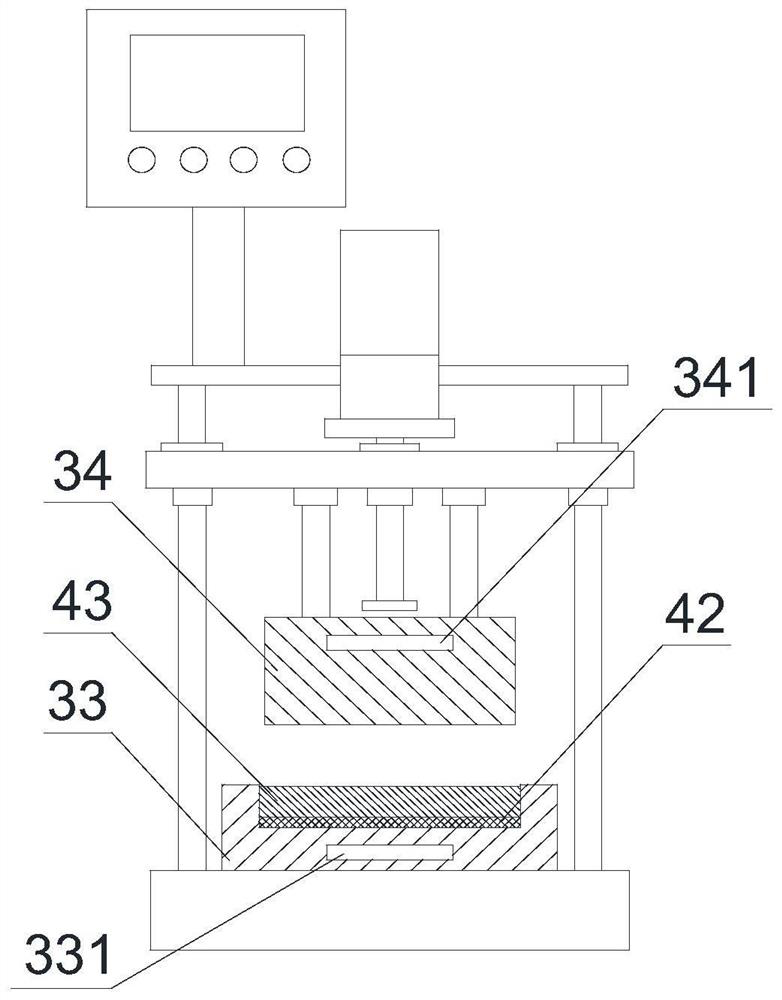

[0065] like Figure 1 to Figure 8 A die-casting system for forming a lithium battery pole piece is shown, including a conveyor belt 1 and a driving wheel 2 for driving the conveyor belt 1 to move. Several die-casting devices 3 are fixedly installed on the conveyor belt 1. The die-casting devices 3 include mutual Matching lower mold 33 and upper mold 34, the lower mold 33 is used to load the current collector 42 and the slurry 43 laid on the upper surface of the current collector 42, and the upper mold 34 is used to extrude the slurry located in the lower mold 33 The slurry 43 and the current collector 42;

[0066] During the movement of the die-casting device 3 along the conveyor belt 1, at least one die-casting cycle is completed. In the die-casting cycle, the lower mold 33 and the upper mold 34 start to cool down after being heated to the drying temperature. During the cooling process, the The upper mold 34 continues to apply pressure to the slurry 43 and the current collec...

Embodiment 2

[0074] On the basis of Example 1, the die-casting cycle includes a charging state, a drying state, a die-casting state and a reclaiming state in sequence, wherein:

[0075] In the charging state, the lower mold 33 is filled with a current collector 42, and the slurry 43 is poured on the current collector 42;

[0076] In the drying state, the upper mold 34 and the lower mold 33 are heated to the drying temperature;

[0077] In the die-casting state, the temperature of the upper mold 34 and the lower mold 33 continues to decrease, and the upper mold 34 squeezes the current collector 42 and the slurry 43 in the lower mold 33;

[0078] In the reclaiming state, the pressure applied by the upper mold 34 on the lithium battery pole piece is removed, and the lithium battery pole piece is taken out from the lower mold 33;

[0079] The temperature of the upper mold 34 and the lower mold 33 in the die-casting state is lower than the temperature of the upper mold 34 and the lower mold 33...

Embodiment 3

[0083] On the basis of the above-mentioned embodiments, the die-casting state includes a final state and at least one pre-pressed state. In the final state, the upper mold 34 applies a final pressure to the current collector 42 and the slurry 43. In the pre-pressed state Next, the upper mold 34 applies an intermediate pressure to the current collector 42 and the slurry 43, and the pressure value of the intermediate pressure is smaller than the pressure value of the final pressure; when reaching the pre-pressed state or the final state, the upper mold 34 remains Current stress for a while.

[0084] This embodiment is not only conducive to the uniform spreading of the slurry, but also beneficial to the drying of the slurry during the drying process at reduced speed, and can further prevent the rebound of the pole piece, and finally achieve the required compaction density.

[0085] In one or more embodiments, the obtained battery electrode sheet for the positive electrode has a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com