Split type impeller

A split-type, impeller technology, applied in non-variable-capacity pumps, liquid fuel engines, components of pumping devices for elastic fluids, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

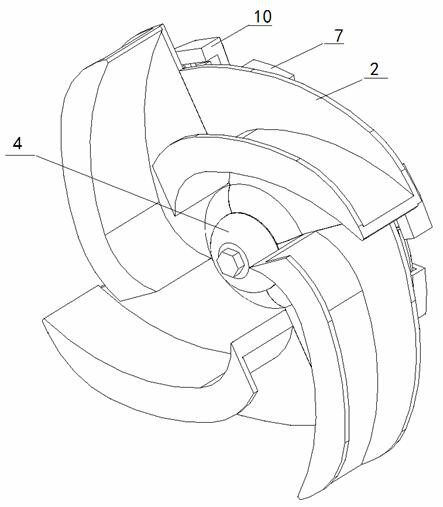

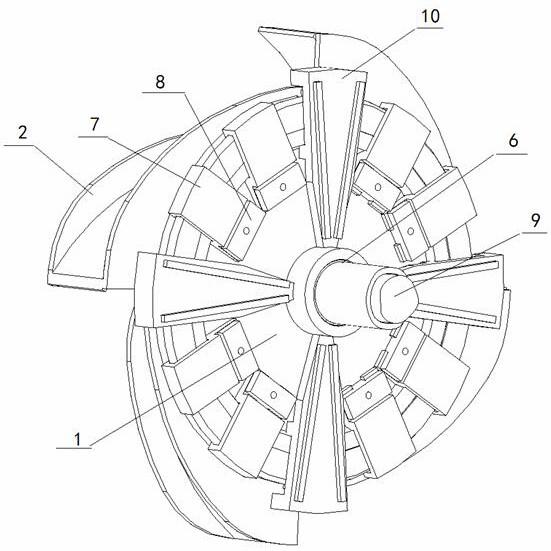

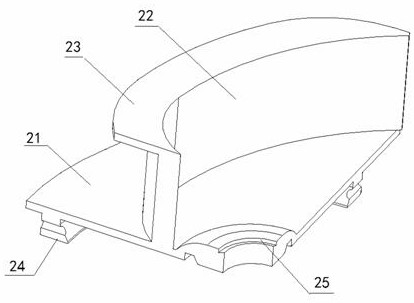

[0032] Such as Figure 1-13 As shown, a split impeller includes impeller main board 1, combined impeller 2, pressure ring 3, shunt protective cap 4, hoop lock 5, spindle stress unloading device 6, lock plate 7, lock slide plate 8 And the protective wear-resistant plate 10, four detachable and replaceable combined impellers 2 are snapped on the end surface of the impeller main board 1, and the center of the impeller main board 1 is provided with a pressure ring 3 that presses the four combined impellers 2. The screw is put together on the main board of the impeller 1, and the end of the crush 3 is provided with a shunt protective cap 4 to seal it. Through the shunt protective cap 4, the sand, stone, water, mud, etc. washed out can be shunted, and the pressure ring can be prevented. 3 and above the screws received shock and corrosion. The outer end of the combined impeller 2 is provided with a hoop lock 5 for fixing them to each other, and a main shaft 9 is threaded into the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com