High-strength aluminum veneer for building outer wall

A high-strength technology for building exterior walls, applied in construction, building structure, covering/lining, etc., can solve the problems of affecting the aesthetics of aluminum veneer decoration, poor bearing capacity, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

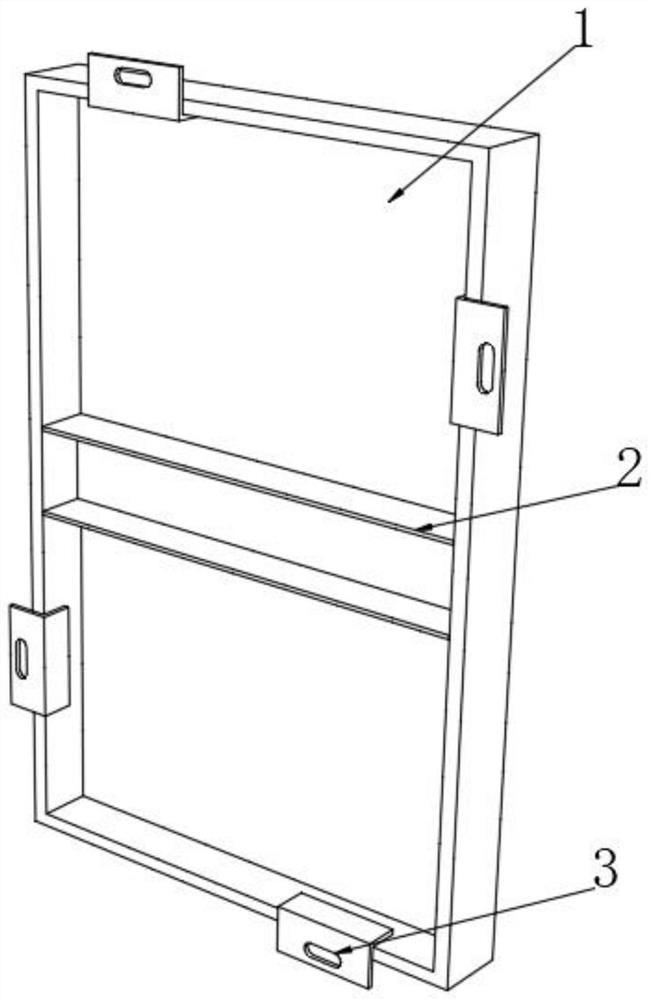

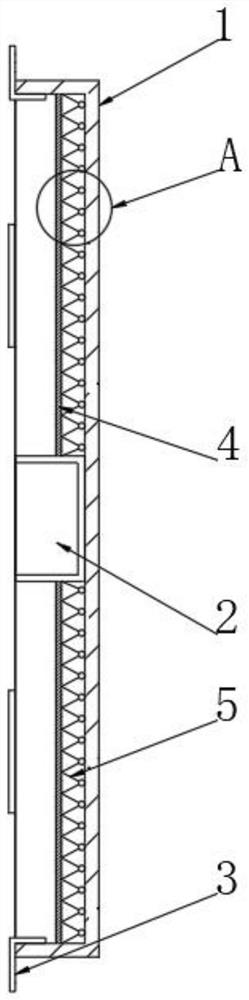

[0048] see figure 1 , a high-strength aluminum veneer for building exterior walls, comprising a veneer body 1, the four edges of the veneer body 1 are connected with aluminum crossbars 3 by bolts, and the middle part of the inner side of the veneer body 1 is fixed with reinforcing ribs by bolts 2.

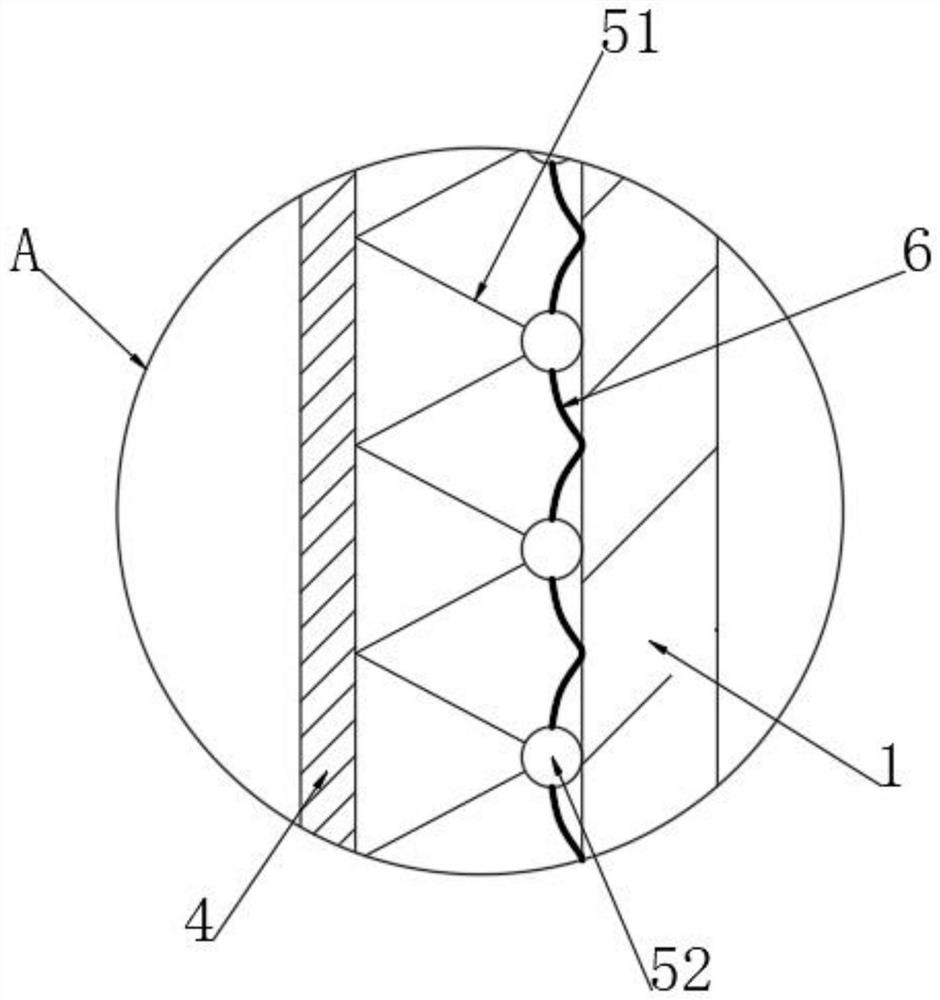

[0049] see Figure 2-4 , the upper and lower ends of the reinforcing rib 2 are fixedly connected with the inner top and inner bottom of the veneer body 1 with an inner support plate 4, and a plurality of multi-legged top balls 5 are arranged between the inner support plate 4 and the inner wall of the veneer body 1 The multi-legged header 5 includes a plurality of diagonal braces 51 fixedly connected to the inner support plate 4 and a force-dissipating ball 52 fixedly connected to the ends of the plurality of diagonal braces 51 .

[0050] 6 is fixedly connected between the heads of two adjacent multi-legged top balls 5, and the middle part of 6 is in contact with the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com