Fluorinated silicon dioxide nanoparticles and application

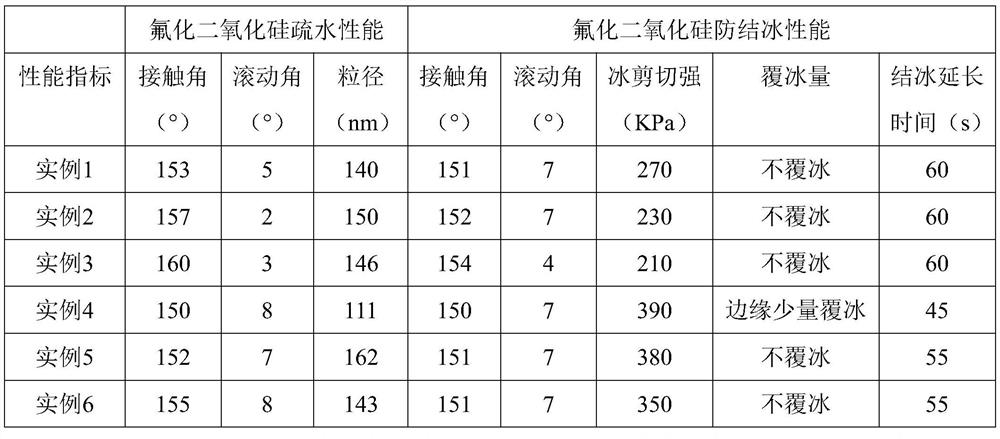

A fluorinated silica and nanoparticle technology, applied in coatings and other directions, can solve problems such as the decline of superhydrophobicity and anti-icing performance of coatings, affecting the promotion of coatings, and the easy agglomeration and dispersion of nanoparticles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

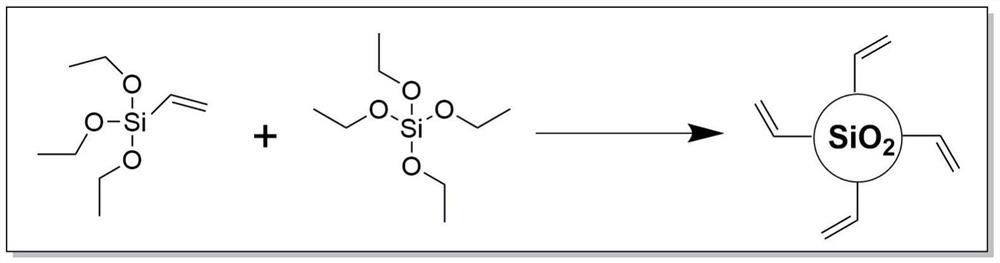

[0026] (1) Add 5.7g vinyltriethoxysilane (30mmol), 6.2g tetraethyl orthosilicate (30mmol), 30mL ethanol as solvent, and 3mL ammonia solution into the flask, react at room temperature for 12h, and spin dry the solvent after the reaction , 50 ° C vacuum drying to obtain 10.0 g white solid product vinyl silica.

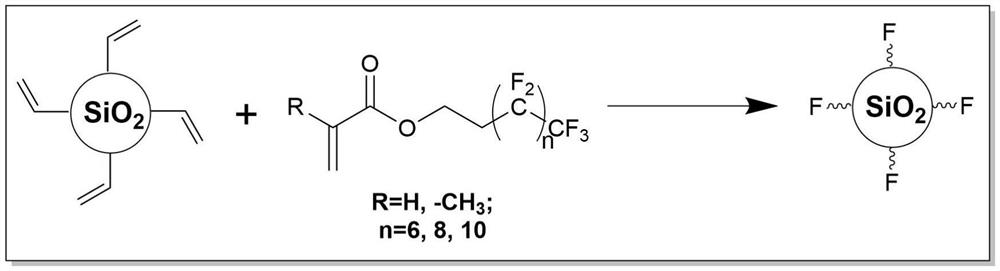

[0027] (2) Add 10.0g vinyl silica, 12.5g perfluorohexylethylacrylic acid (30mmol), 50mL ethanol as solvent, and 0.5g azobisisobutyronitrile into the flask, react at 78°C for 12h, spin Dry the solvent and vacuum-dry at 50°C to obtain 20.5 g of white solid product fluorinated silicon dioxide.

[0028] (3) Dissolving 1.0 g of the prepared fluorinated nano silicon dioxide in ethanol to make a 30% solution. Then the prepared solution was sprayed on the substrate, and dried at 100° C. for 6 hours to obtain the anti-icing coating.

Embodiment 2

[0030] (1) Add 5.7g vinyltriethoxysilane (30mmol), 6.2g tetraethyl orthosilicate (30mmol), 30mL ethanol as solvent, and 3mL ammonia solution into the flask, react at room temperature for 12h, and spin dry the solvent after the reaction , 50 ° C vacuum drying to obtain 13.2 g white solid product vinyl silica.

[0031] (2) Add 10.0g of vinyl silica, 15.5g of perfluorooctylethylacrylic acid (30mmol), 50mL of ethanol as solvent, and 0.5g of azobisisobutyronitrile into the flask, and react at 78°C for 12h. The solvent was spin-dried and vacuum-dried at 50° C. to obtain 23.1 g of white solid product fluorinated silicon dioxide.

[0032] (3) Dissolving 1.0 g of the prepared fluorinated nano silicon dioxide in ethanol to make a 30% solution. Then the prepared solution was sprayed on the substrate, and dried at 100° C. for 6 hours to obtain the anti-icing coating.

Embodiment 3

[0034] (1) Add 5.7g vinyltriethoxysilane (30mmol), 6.2g tetraethyl orthosilicate (30mmol), 30mL ethanol as solvent, and 3mL ammonia solution into the flask, react at room temperature for 12h, and spin dry the solvent after the reaction , 50 ° C vacuum drying to obtain 13.2 g white solid product vinyl silica.

[0035] (2) Add 10.0g of vinyl silica, 18.5g of perfluorodecylethylacrylic acid (30mmol), 50mL of ethanol as solvent, and 0.5g of azobisisobutyronitrile into the flask, and react at 78°C for 12h. The solvent was spin-dried and vacuum-dried at 50° C. to obtain 22.8 g of white solid product fluorinated silicon dioxide.

[0036] (3) Dissolving 1.0 g of the prepared fluorinated nano silicon dioxide in ethanol to make a 30% solution. Then the prepared solution was sprayed on the substrate, and dried at 100° C. for 6 hours to obtain the anti-icing coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com