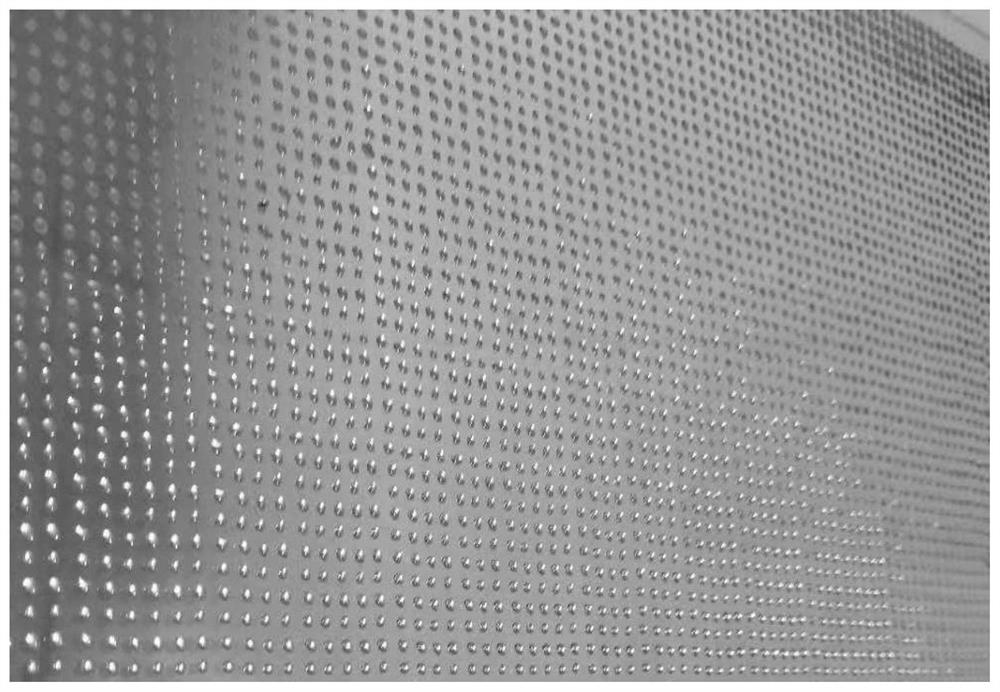

Glass coated with metal refractive raindrops on surface, and preparation process thereof

A surface coating and preparation process technology, applied in coatings, epoxy resin coatings, etc., can solve problems such as poor adhesion, and achieve the effects of strong adhesion, good shrinkage, and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A glass whose surface is coated with metal refraction raindrops comprises a glass plate, the glass plate is provided with an aluminum oxide layer with a thickness of 0.05mm, and the metal refraction raindrops formed by contraction and curing of an epoxy composition are provided on the aluminum oxide layer.

[0043] The preparation process of the glass whose surface is coated with metal refraction raindrops comprises the following preparation steps:

[0044] (1) Clean the glass plate, electroplate the transition layer on the glass surface after cleaning, clean and dry again;

[0045] (2) Add 12.5 parts of brominated bisphenol A type epoxy resin, 10 parts of novolak epoxy resin, 8 parts of triphenylmethane triisocyanate and 9.5 parts of AG-80 four-functional epoxy resin to 12 parts of organic solvent ethylene ethyl alcohol Stir evenly in the glycol ether. After the resin dissolves, an epoxy resin mixture with a viscosity of 4200CPS is obtained. Continue to add 1 part of c...

Embodiment 2

[0049] A glass whose surface is coated with metal refraction raindrops comprises a glass plate, the glass plate is provided with an aluminum oxide layer with a thickness of 0.02 mm, and the metal refraction raindrops formed by shrinking and curing an epoxy composition are provided on the aluminum oxide layer.

[0050] The preparation process of the glass whose surface is coated with metal refraction raindrops comprises the following preparation steps:

[0051] (1) Clean the glass plate, electroplate the transition layer on the glass surface after cleaning, clean and dry again;

[0052] (2) Add 10 parts of brominated bisphenol A epoxy resin, 12 parts of novolac epoxy resin, 5 parts of triphenylmethane triisocyanate and 12 parts of AG-80 tetrafunctional epoxy resin to 8-15 parts of organic solvent Stir evenly in trichlorethylene, and after the resin dissolves, an epoxy resin mixture with a viscosity of 4000CPS is obtained. Continue to add 1.2 parts of curing accelerator salicyli...

Embodiment 3

[0056] A glass whose surface is coated with metal refraction raindrops comprises a glass plate, the glass plate is provided with an aluminum oxide layer with a thickness of 0.08mm, and the metal refraction raindrops formed by shrinking and curing the epoxy composition are provided on the aluminum oxide layer.

[0057] The preparation process of the glass whose surface is coated with metal refraction raindrops comprises the following preparation steps:

[0058] (1) Clean the glass plate, electroplate the transition layer on the glass surface after cleaning, clean and dry again;

[0059] (2) 10 parts of brominated bisphenol A type epoxy resin, 12 parts of novolac epoxy resin, 10 parts of triphenylmethane triisocyanate and 12 parts of AG-80 four-functional epoxy resin are added to 15 parts of organic solvent triethanolamine Stir evenly in the middle, and after the resin dissolves, an epoxy resin mixture with a viscosity of 4500CPS is obtained. Continue to add 1.2 parts of curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com