Multi-size micro-nano metal particle soldering paste in-situ interconnection process and product thereof

A metal particle, micro-nano technology, used in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of high paste sintering temperature, easy oxidation of nano copper particles, and complicated solder paste preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

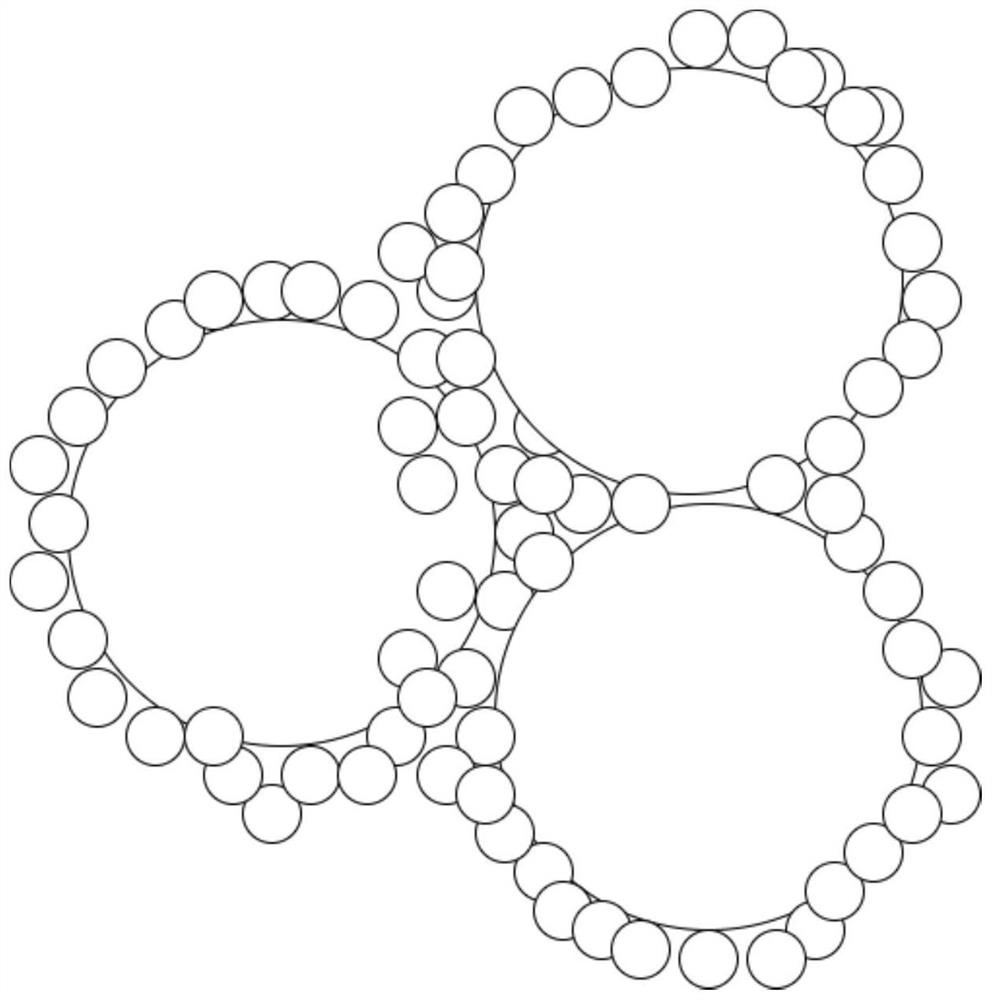

Image

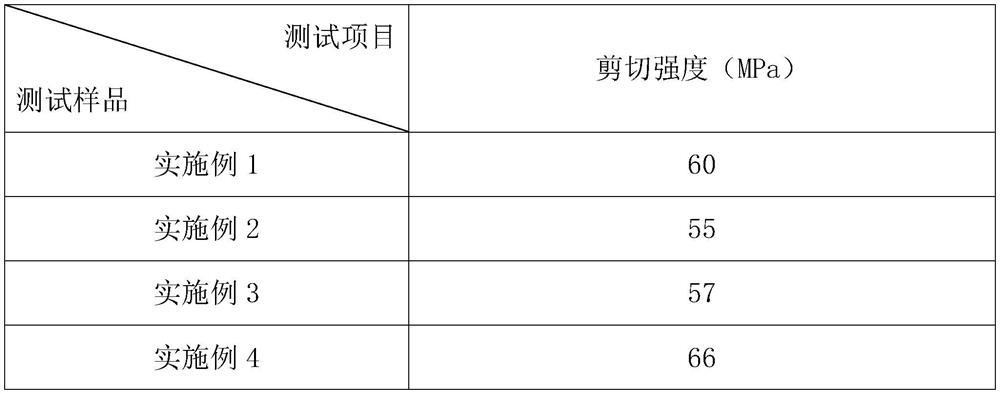

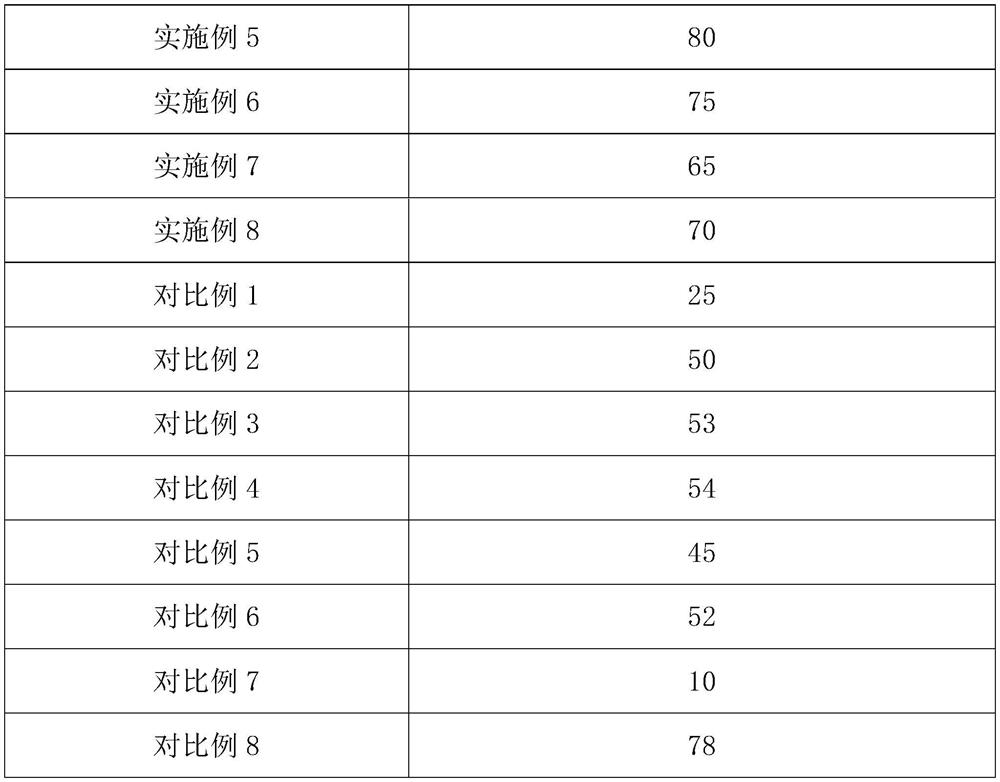

Examples

Embodiment 1

[0056] An in-situ interconnection process of multi-size micro-nano metal particle solder paste, comprising the following steps:

[0057] (a) Dissolve the copper salt (specifically copper acetate) in a solvent (specifically 500mL ethylene glycol) at 50°C, add a reducing agent (specifically ascorbic acid) and micron metal particles (specifically ethylene glycol) into the solvent 1 μm copper particles), wherein the molar ratio of copper salt to reducing agent is 1:6, and the molar ratio of copper salt to micron metal particles is 1:1, and the multi-size micronano metal particle dispersion is obtained after stirring and reacting for 20 minutes;

[0058] (b) Concentrating the multi-size micro-nano metal particle dispersion prepared in the step (a), pouring the multi-size micro-nano metal particle dispersion prepared in the step (a) into a centrifuge tube In, under the condition of 12000r / min, centrifuge 5min in centrifuge, then stir to make multi-size micro-nano metal particle sold...

Embodiment 2

[0061] An in-situ interconnection process of multi-size micro-nano metal particle solder paste, comprising the following steps:

[0062] (a) Dissolve the copper salt (specifically copper acetate) in a solvent (specifically 500mL ethylene glycol) at 50°C, add a reducing agent (specifically ascorbic acid) and micron metal particles (specifically ethylene glycol) into the solvent 1 μm copper particles), wherein the molar ratio of copper salt to reducing agent is 1:1, and the molar ratio of copper salt to micron metal particles is 1000:1, and the multi-size micronano metal particle dispersion is obtained after stirring and reacting for 20 minutes;

[0063] (b) Concentrating the multi-size micro-nano metal particle dispersion prepared in the step (a), pouring the multi-size micro-nano metal particle dispersion prepared in the step (a) into a centrifuge tube In, under the condition of 12000r / min, centrifuge 5min in centrifuge, then stir to make multi-size micro-nano metal particle s...

Embodiment 3

[0066] An in-situ interconnection process of multi-size micro-nano metal particle solder paste, comprising the following steps:

[0067] (a) Dissolve the copper salt (specifically copper acetate) in a solvent (specifically 500mL ethylene glycol) at 50°C, add a reducing agent (specifically ascorbic acid) and micron metal particles (specifically ethylene glycol) into the solvent 1 μm copper particles), wherein the molar ratio of copper salt to reducing agent is 1:10, and the molar ratio of copper salt to micron metal particles is 1:10, and the multi-size micronano metal particle dispersion is obtained after stirring and reacting for 20 minutes;

[0068] (b) Concentrating the multi-size micro-nano metal particle dispersion prepared in the step (a), pouring the multi-size micro-nano metal particle dispersion prepared in the step (a) into a centrifuge tube In, under the condition of 12000r / min, centrifuge 5min in centrifuge, then stir to make multi-size micro-nano metal particle so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com