Method for preparing Co/3DNG catalyst and applying Co/3DNG catalyst to catalytic oxidation of lignin and beta-O-4 model compound thereof

A technology of 3DNG and catalyst, applied in the application field of oxidative transformation of lignin and its β-O-4 model compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

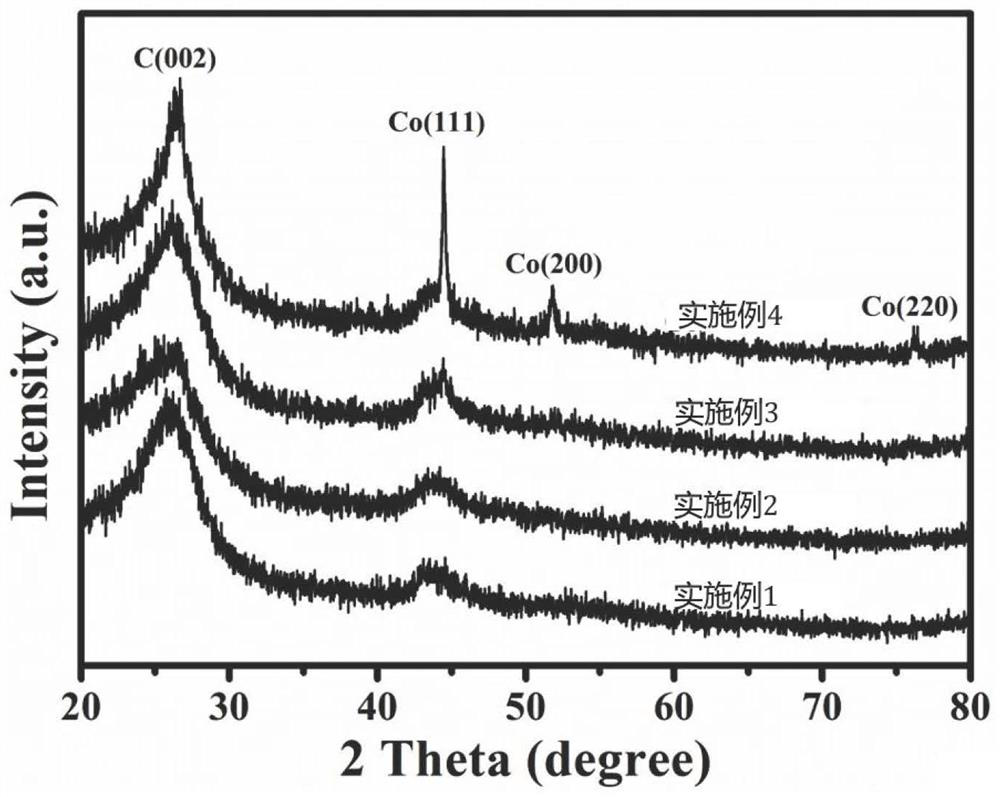

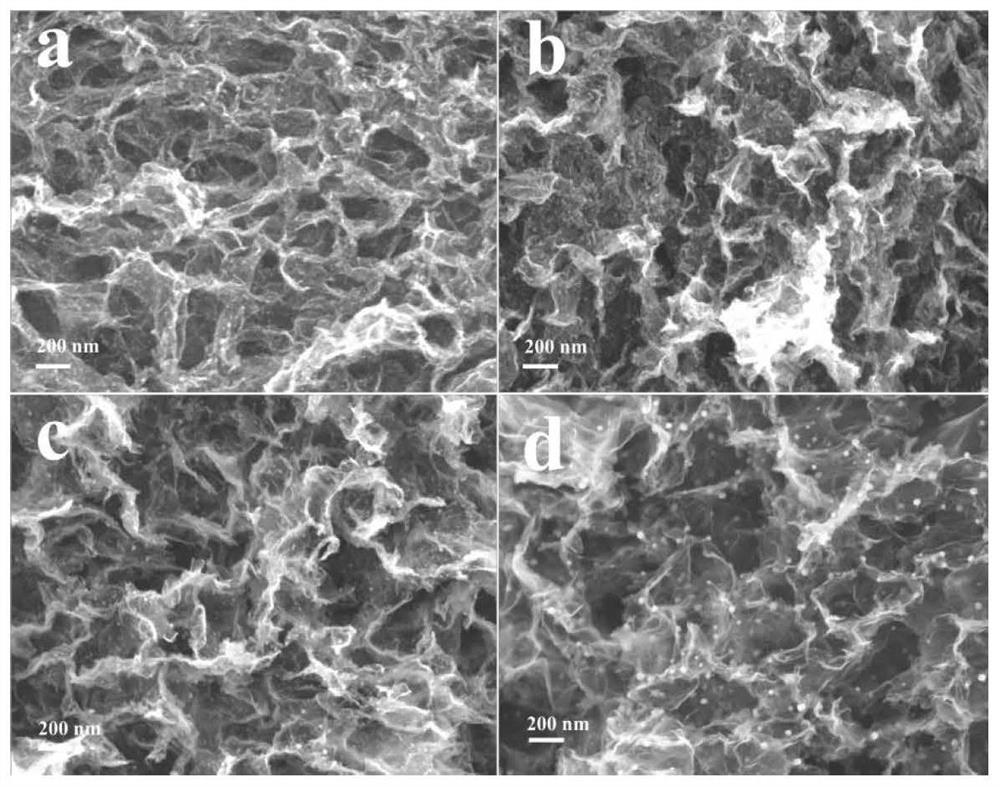

Embodiment 1

[0032] This embodiment specifically includes the following steps:

[0033] Step 1. Add 20mL, 2mg / mL GO dispersion into a 40mL hydrothermal kettle, and then measure 0.5mL NH 3 ·H 2 O was added to the GO dispersion and stirred thoroughly for 5 min. Then, the reaction kettle was transferred to an oven, heated to 180° C., and kept at this temperature for 12 hours. After the reaction is finished and the reaction kettle is naturally cooled, the product system is centrifuged, washed with deionized water until neutral pH = 7, and stored in deionized water for future use. The resulting product was named 3DNG.

[0034] Step 2, weigh 10mg Co(CH 3 COO) 2 4H 2 O, successively measure 7mL of deionized water and 7mL of absolute ethanol, and stir thoroughly for 10min. The 3DNG was then immersed in the Co salt solution and allowed to stand for 24 h. Then, the impregnated 3DNG was washed several times in a mixed solution of ethanol and water (1:1), and the product was placed in a refrig...

Embodiment 2

[0039] This embodiment specifically includes the following steps:

[0040] In the first step, add 20mL, 3mg / mL GO dispersion into a 40mL hydrothermal kettle, and then measure 1.0mL NH 3 ·H 2 O was added to the GO dispersion and stirred thoroughly for 5 min. Then, the reaction kettle was transferred to an oven, heated to 180°C, and kept at this temperature for 12h. After the reaction was completed and the reactor was naturally cooled, the product was transferred to deionized water for dialysis until the pH of the deionized water was 7, and the obtained product was named 3DNG.

[0041] The second step, weigh 20mg Co(CH 3 COO) 2 4H 2 O, successively measure 7mL of deionized water and 7mL of absolute ethanol, and stir thoroughly for 10min. The 3DNG was then immersed in the Co salt solution and allowed to stand for 24 h. Then, the impregnated 3DNG was washed several times in a mixed solution of ethanol and water (1:1), and the product was placed in a refrigerator (-25°C) for...

Embodiment 3

[0046] This embodiment specifically includes the following steps:

[0047] Step 1. Add 20mL, 4mg / mL GO dispersion into a 40mL hydrothermal kettle, and then measure 1.5mL NH 3 ·H 2 O was added to the GO dispersion and stirred thoroughly for 5 min. Then, the reaction kettle was transferred to an oven, heated to 180°C, and kept at this temperature for 12h. After the reaction was completed and the reactor was naturally cooled, the product was transferred to deionized water for dialysis until the pH of the deionized water was 7, and the obtained product was named 3DNG.

[0048] Step 2. Weigh 30mg Co(CH3COO) 2 4H 2 O, successively measure 7mL of deionized water and 7mL of absolute ethanol, and stir thoroughly for 10min. The 3DNG was then immersed in the Co salt solution and allowed to stand for 24 h. Then, the impregnated 3DNG was washed several times in a mixed solution of ethanol and water (1:1), and the product was placed in a refrigerator (-25°C) for 12 hours, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com