Oil refining device fractionating tower top corrosion risk monitoring system

A technology for oil refining equipment and risk monitoring, which is applied in the directions of measuring equipment, weather resistance/light resistance/corrosion resistance, analysis materials, etc., and can solve the problems of corrosion risk and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

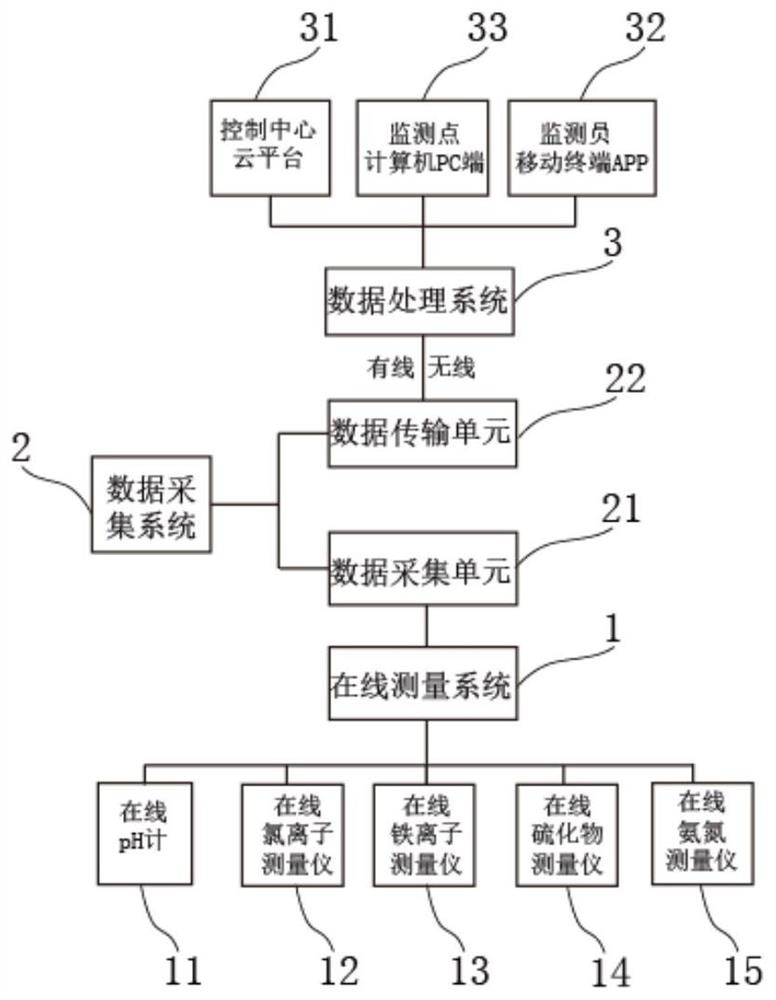

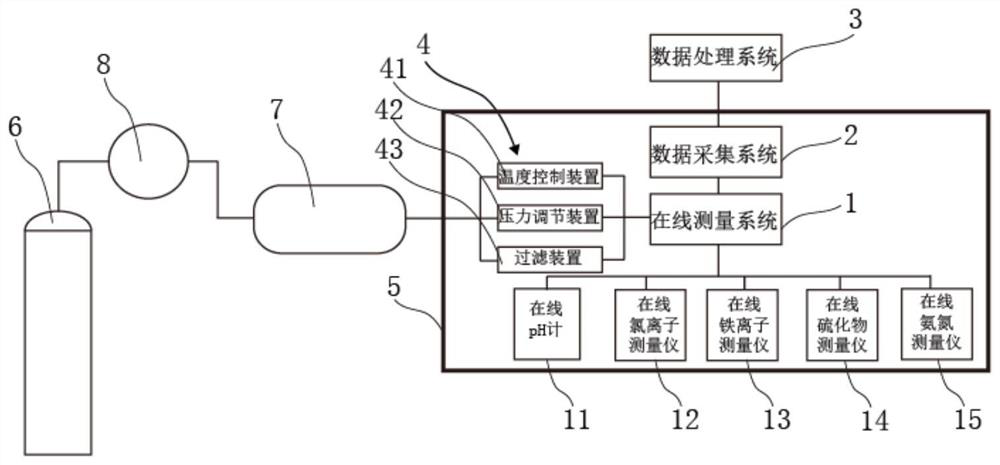

[0048] combine figure 1 and figure 2 , Atmospheric fractionation tower 6 of an atmospheric and vacuum unit is equipped with an oil refinery fractionation tower top corrosion risk monitoring system of the present invention, including an online measurement system 1, a data acquisition system 2, a data processing system 3 and an explosion-proof system 5. The on-line pH meter 11 in the on-line measurement system 1 uses an anti-sulfide poisoning sensor; the on-line chloride ion measuring instrument 12 uses the chloride ion selective electrode method with a range of 0-500 mg / L; the on-line iron ion measuring instrument 13 uses o-phenanthroline spectroscopic Photometric method, measuring range is 0~8mg / L; On-line sulfide measuring instrument 14 adopts sulfur ion indicating electrode titration method, measuring range is 0~500mg / L; Online ammonia nitrogen measuring instrument 15 adopts gas sensitive electrode method, measuring range is 0~1000mg / L L. The on-line measurement system 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com