Coating layer-carried aero-engine part cleanness checking method and device thereof

An aero-engine and inspection method technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, measuring devices, etc., to achieve good cleaning quality, prevent surface corrosion of parts, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

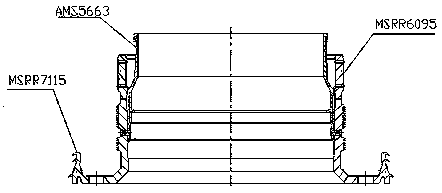

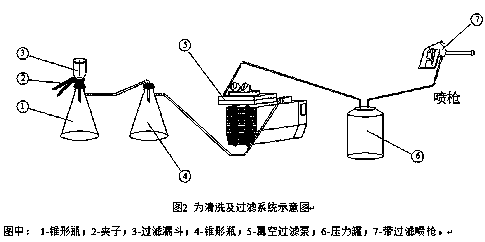

[0028] Embodiment 1: certain aero-engine parts with coating (see figure 1 (shown) is assembled from nickel-based high-temperature alloy, bearing steel, and stainless steel. Bearing steel material is easy to rust. Therefore, in order to avoid corrosion of parts and obtain good inspection results during cleaning and cleanliness inspection, an automatic cleaning machine is used for pre-cleaning. The cleaning solvent is petroleum. ether; from figure 1 It can be seen from the middle view that after the parts are assembled, there are many grooves, pores and teeth on the parts. The general simple soaking method is difficult to achieve the expected cleaning effect. In order to obtain a good cleaning effect, the method of pressure spraying petroleum ether is used. Cleaning, the specific steps are as follows:

[0029] (1) Use FRD-4000-PCS automatic cleaning machine to pre-clean, first use 3.72% (volume ratio) M-AERO-NS water-based cleaning solution to spray at 80°C for 4min; then heat...

Embodiment 2

[0036] Example 2: The difference between this example and Example 1 is that the content of the water-based cleaning solution of M-AERO-NS in step (1) in this example is 1.57% (volume ratio); Put the parts in an oven and dry for 90 minutes; the test result in step (6) is that the number of hard particles larger than 30 μm and smaller than 100 μm is 2;

Embodiment 3

[0037] Example 3: The difference between this example and Example 1 is that the content of the water-based cleaning solution of M-AERO-NS in step (1) in this example is 4.52% (volume ratio), and then the Spray with ion water for 1 minute; finally dry with clean hot air at 85°C for 3 minutes; in step (2), put the parts in an oven to dry for 120 minutes; in step (6), the test result shows that the hard particles are larger than 30 μm and less than 100 μm The number of is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com