Composite multi-layer stab-resistant bulletproof fabric piece and preparation method thereof

A bullet-proof cloth and stab-proof technology, applied in protective equipment, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem that the stab-proof and bullet-proof effect cannot be guaranteed, the stab-proof bulletproof cloth has a rough structure, and cannot guarantee long-term Use and other issues to achieve the effect of improving comfort and flexibility, enhancing overall structural performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Another technical solution provided by the present invention is to provide a method for preparing a composite multi-layer stab-proof and bullet-proof cloth sheet, the preparation method comprising the following steps;

[0033] Step 1: Take ultra-high molecular weight polyethylene fiber, aramid fiber, carbon fiber, PBO fiber and a small amount of polybutylene terephthalate with an overall mass ratio of 3.6-4.5:1:0.6-0.75:0.35-0.55:0.1-0.15 Alcohol ester fiber;

[0034] Step 2: In the step aramid fiber, meta-aramid fiber filaments and meta-aramid fiber short filaments are used in a ratio of 0.8 to 1.3:3;

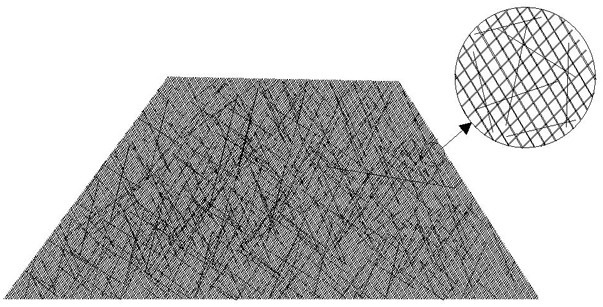

[0035] Step 3: Evenly blend polyethylene fibers, meta-aramid fiber filaments, carbon fibers, PBO fibers and elastomer fibers, and the meso-aramid fiber short filaments are overlapped in an uneven state and added to blending to make it blended into a single layer of gauze;

[0036] The angle between the warp and weft during the blending operation is 60°-120°;

[0037]...

Embodiment 1

[0043] When making stab-proof and bullet-proof cloth, firstly take ultra-high molecular weight polyethylene fiber, aramid fiber, carbon fiber, PBO fiber and a small amount of polybutylene terephthalate with an overall mass ratio of 4.2:1:0.7:0.45:0.1 Glycol ester fibers, wherein the fibers are prepared sequentially through a twin-screw extruder, a spinning box, a spinneret, extraction, drying, heating and drawing, and winding;

[0044] Among them, the aramid fiber adopts the meta-aramid fiber filament and the meta-aramid fiber short filament with a ratio of 1:3, and the meta-aramid fiber filament with an average wire diameter of 42 μm and the meta-aramid fiber filament with an average wire diameter of 95 μm are used. Aramid fiber staple;

[0045]Evenly blend polyethylene fibers, meta-aramid fiber filaments, carbon fibers, PBO fibers and elastomer fibers, and the meta-aramid fiber short filaments are overlapped in an uneven state and added to blending, so that they are blended ...

Embodiment 2

[0049] When making stab-proof and bullet-proof cloth, firstly take ultra-high molecular weight polyethylene fiber, aramid fiber, carbon fiber, PBO fiber and a small amount of polybutylene terephthalate with an overall mass ratio of 3.9:1:0.65:0.5:0.15 Glycol ester fibers, wherein the fibers are prepared sequentially through a twin-screw extruder, a spinning box, a spinneret, extraction, drying, heating and drawing, and winding;

[0050] Among them, the aramid fiber adopts the meta-aramid fiber filament and the meta-aramid fiber short filament with a ratio of 1.2:3, and the meta-aramid fiber filament with an average wire diameter of 38 μm and the meta-aramid fiber filament with an average wire diameter of 108 μm are used. Aramid fiber staple;

[0051] Evenly blend polyethylene fibers, meta-aramid fiber filaments, carbon fibers, PBO fibers and elastomer fibers, and the meta-aramid fiber short filaments are overlapped in an uneven state and added to blending, so that they are ble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com