High-efficiency drying equipment for vital wheat gluten and using method thereof

A drying equipment and technology for gluten, applied in separation methods, drying solid materials, drying gas layout, etc., can solve the problems of unfavorable rapid drying of gluten, long waiting time, long dehydration time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

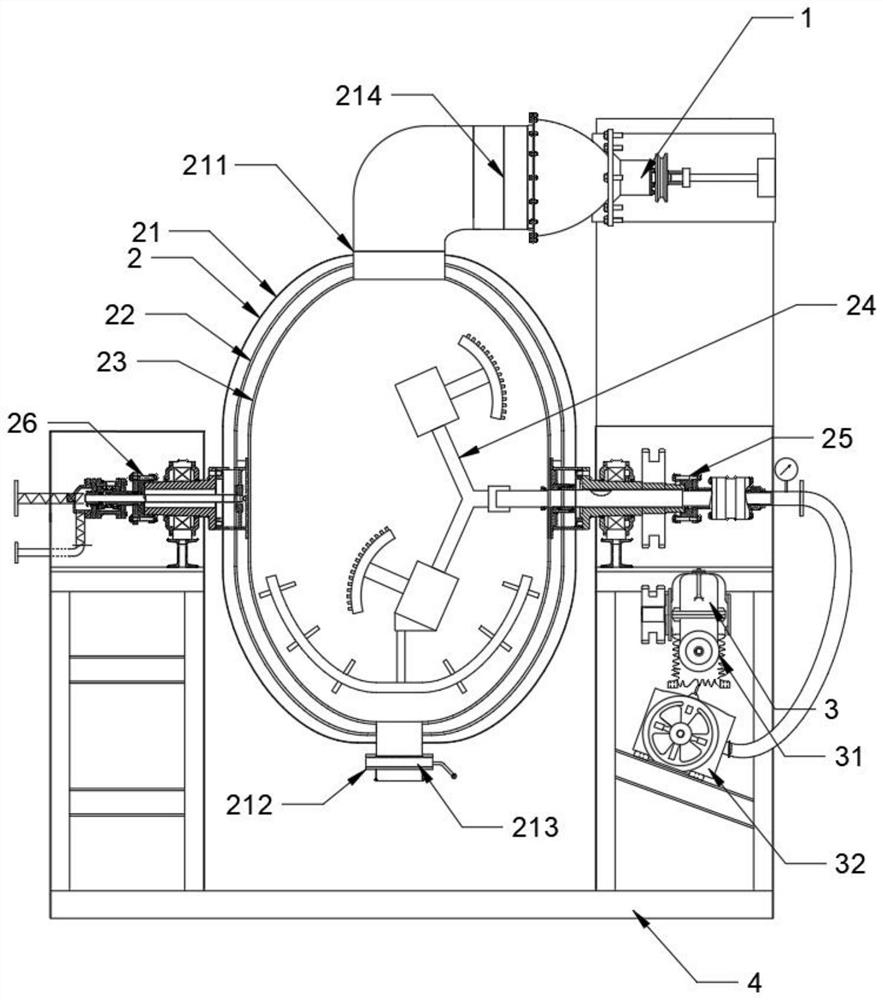

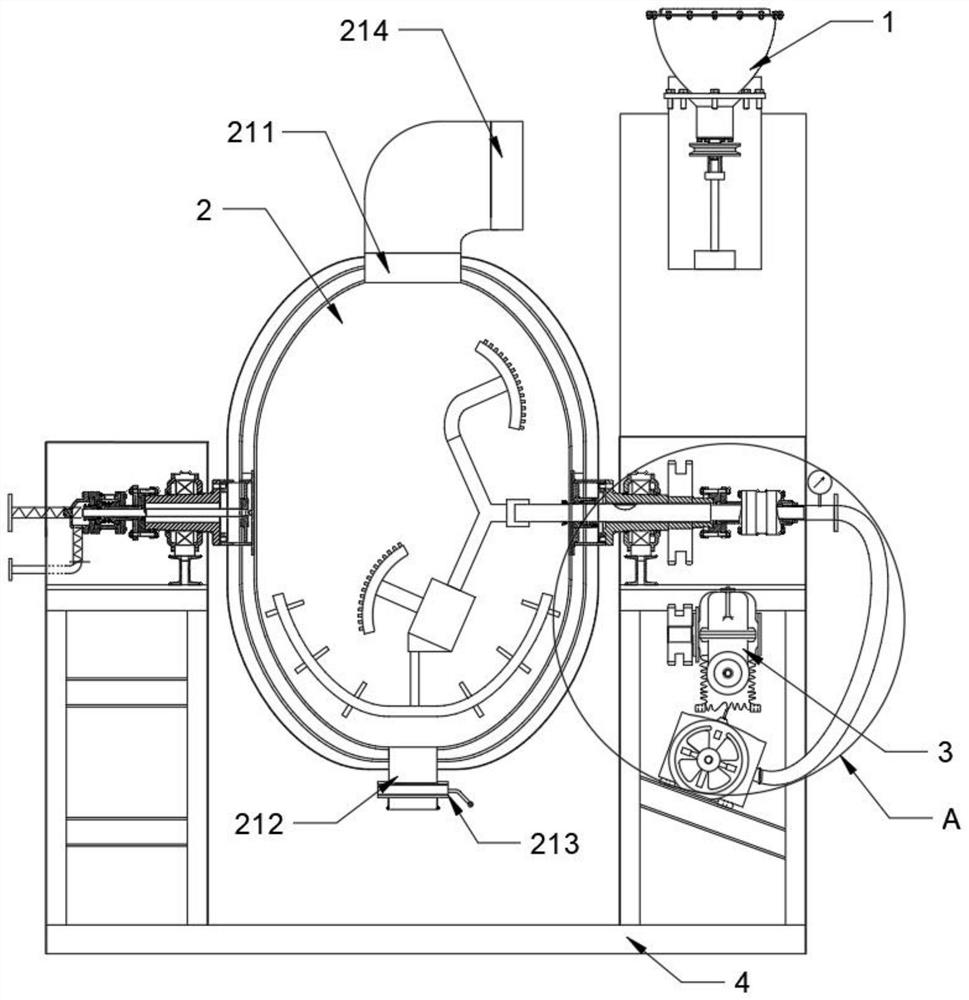

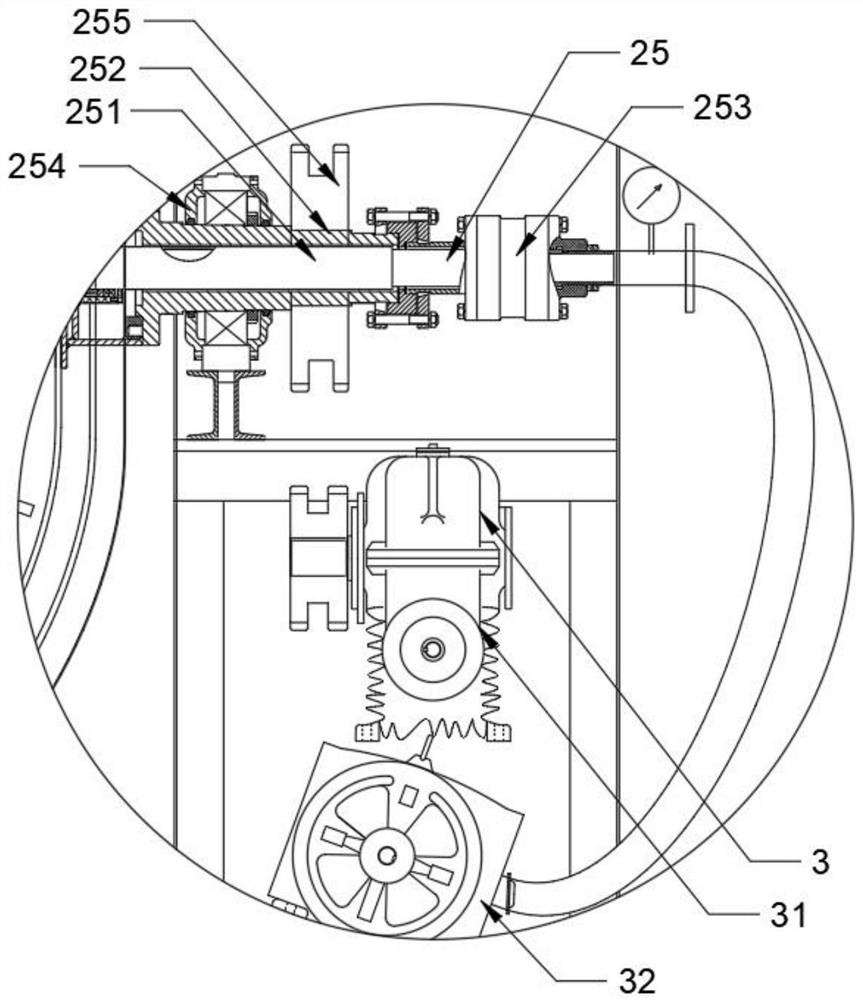

[0052] like Figure 1-9 As shown, the high-efficiency drying equipment for gluten powder includes a centrifugal dehydration assembly 1, and the centrifugal dehydration assembly 1 includes a filter mechanism 11, a fixing mechanism 12, a first pulley 13 and a liner rod 14, and the filter mechanism 11 is movably connected to the upper part of the fixing mechanism 12, The first belt pulley 13 is arranged at the lower part of the fixing mechanism 12 , and the first belt pulley 13 is connected to the filter mechanism 11 through the inner liner rod 14 .

[0053] The centrifugal dehydration assembly 1 in this embodiment is used to realize the rapid automatic dehydration of gluten, wherein the filter mechanism 11 realizes the effect of filtration, wherein the fixing mechanism 12 is used for fixing the equipment, and the first pulley 13 provides power for the rotation of the equipment , the liner rod 14 is used to push the filter mechanism 11 to move up and down, the liner rod 14 rises,...

Embodiment 2

[0060] This embodiment is a further improvement of the previous embodiment, such as Figure 1-9 As shown, the high-efficiency drying equipment for gluten powder includes a centrifugal dehydration assembly 1, and the centrifugal dehydration assembly 1 includes a filter mechanism 11, a fixing mechanism 12, a first pulley 13 and a liner rod 14, and the filter mechanism 11 is movably connected to the upper part of the fixing mechanism 12, The first belt pulley 13 is arranged at the lower part of the fixing mechanism 12 , and the first belt pulley 13 is connected to the filter mechanism 11 through the inner liner rod 14 .

[0061] The centrifugal dehydration assembly 1 in this embodiment is used to realize the rapid automatic dehydration of gluten, wherein the filter mechanism 11 realizes the effect of filtration, wherein the fixing mechanism 12 is used for fixing the equipment, and the first pulley 13 provides power for the rotation of the equipment , the liner rod 14 is used to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com