Double-turbine direct-driven permanent magnet synchronous generator set

A technology of permanent magnet synchronous and generator sets, which is applied in electric components, ocean energy power generation, engine components, etc., and can solve problems such as high sealing performance requirements, increased manufacturing costs, and large structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

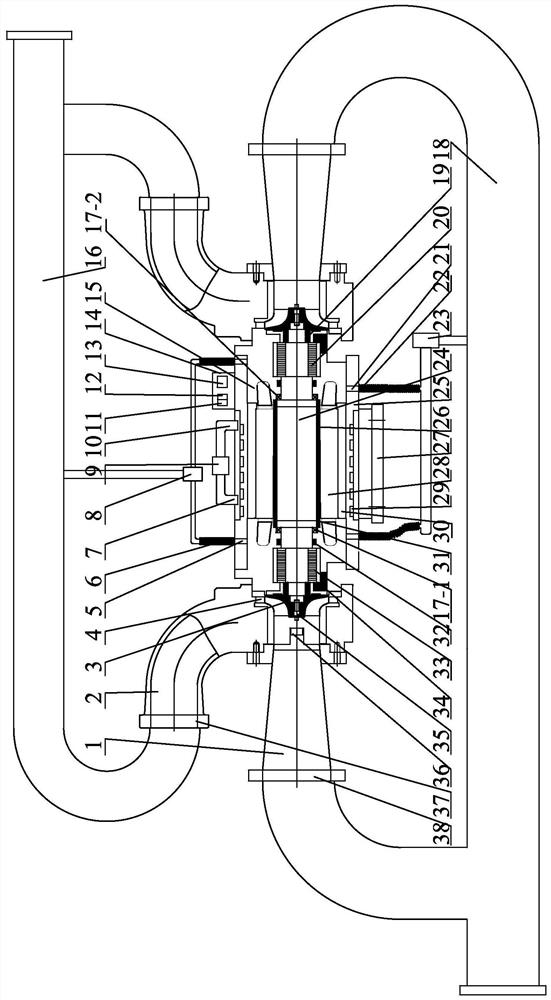

[0058] Such as figure 1 As shown, a magnetic levitation double-turbine direct-drive permanent magnet synchronous generator set includes a permanent magnet synchronous generator and two centripetal turbines located at both ends of the permanent magnet synchronous generator; the generator of the permanent magnet synchronous generator A cooling system is provided on the casing 25; the cooling system includes a cold water system arranged outside the generator casing and a cold air system communicated with the inside of the casing. The rotating shaft of the permanent magnet synchronous generator is in drive connection with the generator casing through the first magnetic suspension bearing 33 , the second magnetic suspension bearing 20 and the auxiliary bearing 17 via the bearing support 34 . The unit is mainly supported by the auxiliary bearing 17 during the start-up operation stage. The permanent magnet synchronous generator includes a generator winding stator core 28 , a rotor c...

Embodiment 2

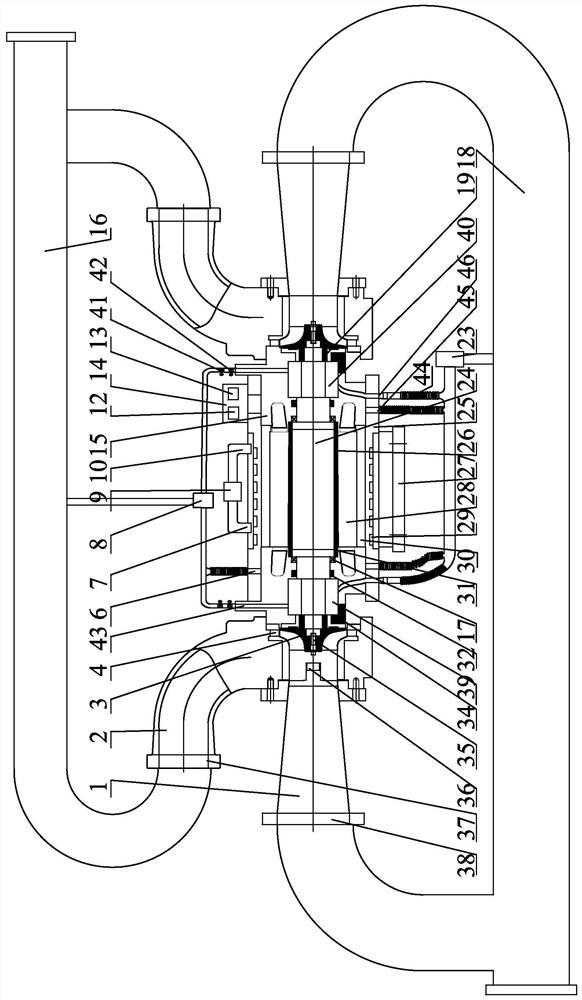

[0071] Such as figure 2 As shown, an air-suspended twin-turbine direct-drive permanent magnet synchronous generator set includes a permanent magnet synchronous generator and two centripetal turbines located at both ends of the permanent magnet synchronous generator; A cooling system is provided on the casing 25; the cooling system includes a cooling water system arranged outside the generator casing and a cooling system connected to the inside of the casing; the cooling system is also used to supply air to the air bearing. The rotating shaft of the permanent magnet synchronous generator is connected to the generator casing through the first air bearing 39, the second air bearing, the auxiliary bearing 40 and the auxiliary bearing 17 through the bearing support 34; the air bearing is embedded in the bearing support Inside the seat 34. The auxiliary bearing is a tapered roller bearing, and the auxiliary bearing can bear axial load and radial load at the same time, and can bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com