Electromagnetic anchor pipe structure and magnetic convergence grouting construction process

An anchor pipe and electromagnetic technology, applied in infrastructure engineering, electromagnets, electromagnets without armatures, etc., can solve the problem that the slurry cannot be completely filled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

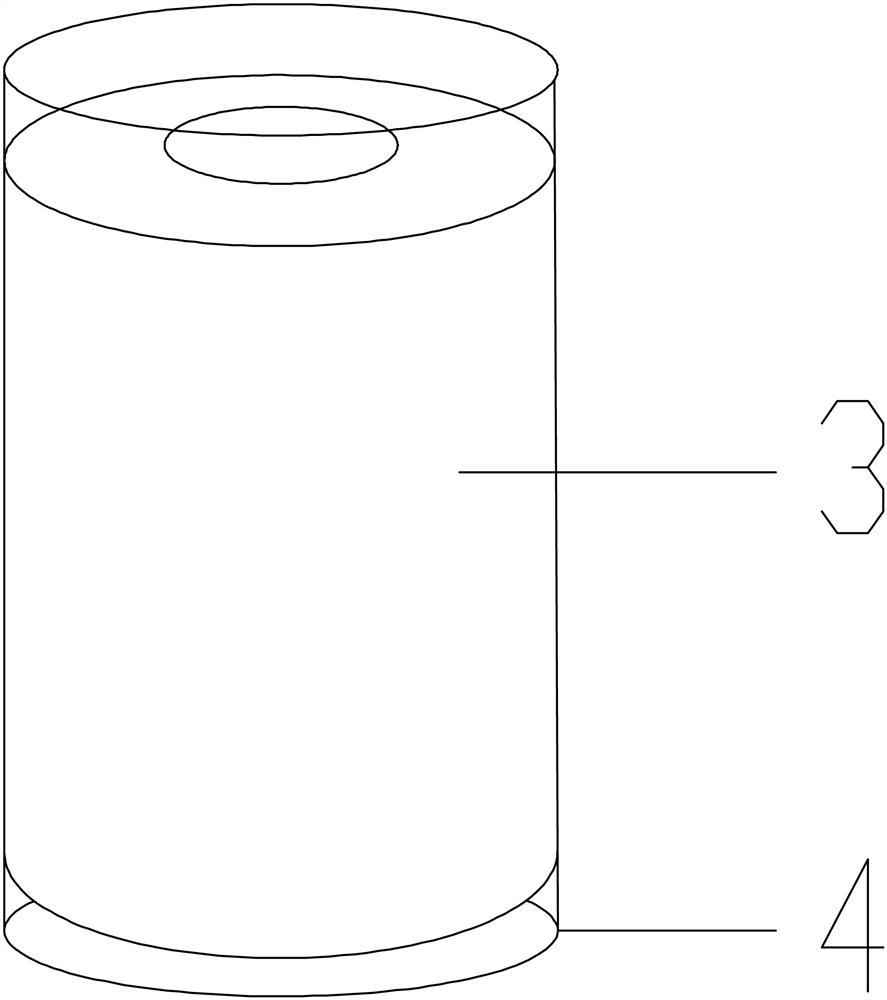

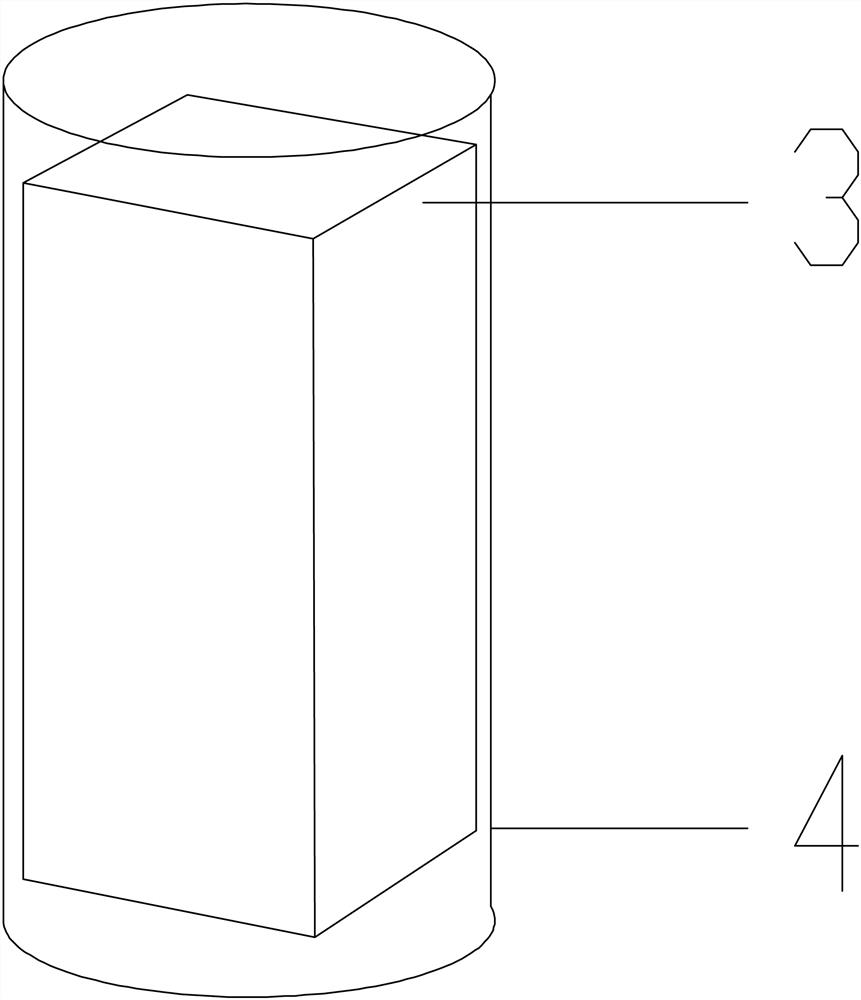

[0074] see Figure 1-6 , an electromagnetic anchor pipe structure, which includes an anchor pipe 4, the interior of the anchor pipe 4 is provided with electromagnets 3 in a variety of different arrangements, and the electromagnet 3 cooperates with the magnetic mortar around the anchor pipe 4 , and adsorb it; the interior of the anchor pipe 4 is filled with cooling oil for cooling the electromagnet 3; when grouting, the top of the anchor pipe 4 is fixed with a high-tightness three-hole seal Plug 13, the three-hole sealing plug 13 is a trapezoidal structure, the lower end is provided with a threaded opening, and the lower end of the three-hole sealing plug is provided with a threaded plug body and a sealing ring extending downward and threaded with the upper end of the inner wall of the anchor pipe 4; The hole sealing plug 13 is provided with a cooling oil injection hole 13-1 for injecting cooling oil, a cooling oil injection hole 13-2 for leading out cooling oil, and a wire hol...

Embodiment 2

[0086] Using any one of the electromagnetic anchor pipe structures to carry out the magnetic convergence grouting construction process includes the following steps:

[0087] When the electromagnetic anchor pipe is used to increase the anchoring force of the anchor head, the construction steps are:

[0088] Step1.1: After the anchor hole is drilled, insert the electromagnetic anchor pipe into the hole;

[0089] Step1.2: Configure the cement-based magnetic convergence slurry, the water-cement ratio is 0.4-0.7, the amount of fly ash is 15%-40% of the mass of cement, and the amount of magnetic powder is 25%-55% of the mass of cement , the magnetic powder dispersant is 8%-15% of the magnetic powder, the flocculant is 4%-7% of the cement mass, the water reducing agent is 3%-6% of the cement mass, and the defoamer is 0.5g-2.0g per 500g slurry The proportion of adding, rust inhibitor 12%-20%, water-soluble silicone oil is 5%-10% of magnetic powder, stir evenly;

[0090] Step1.3: Inj...

Embodiment 3

[0092] In the environment of vertical hole grouting, the construction steps of using electromagnetic anchor pipe and cement-based magnetic convergence grout are as follows:

[0093] Step2.1: Measure the size of the wading anchor hole before the actual construction;

[0094] Step2.2; After the anchor hole is drilled, insert the anchor pipe 4;

[0095] Step2.3: Configure the cement-based magnetic convergence slurry, the water-cement ratio is 0.4-0.7, the amount of fly ash is 15%-40% of the mass of cement, and the amount of magnetic powder is 25%-55% of the mass of cement , the magnetic powder dispersant is 8%-15% of the magnetic powder, the flocculant is 4%-7% of the cement mass, the water reducing agent is 3%-6% of the cement mass, and the defoamer is 0.5g-2.0g per 500g slurry The proportion of adding, rust inhibitor 12%-20%, water-soluble silicone oil is 5%-10% of the magnetic powder.

[0096] Step2.4: Inject the configured cement-based magnetic convergence grout into the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com