Preparation method of a bridge-type strong corner point FRP frame

A glass fiber reinforced plastic and strong corner point technology is applied in the field of preparation of bridge type strong corner point glass fiber reinforced plastic frames, which can solve problems such as mechanical fatigue damage, frame deformation, and quality impact, so as to improve the compressive strength, improve the molding effect, and improve the overall pre-conditioning. The effect of stress intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

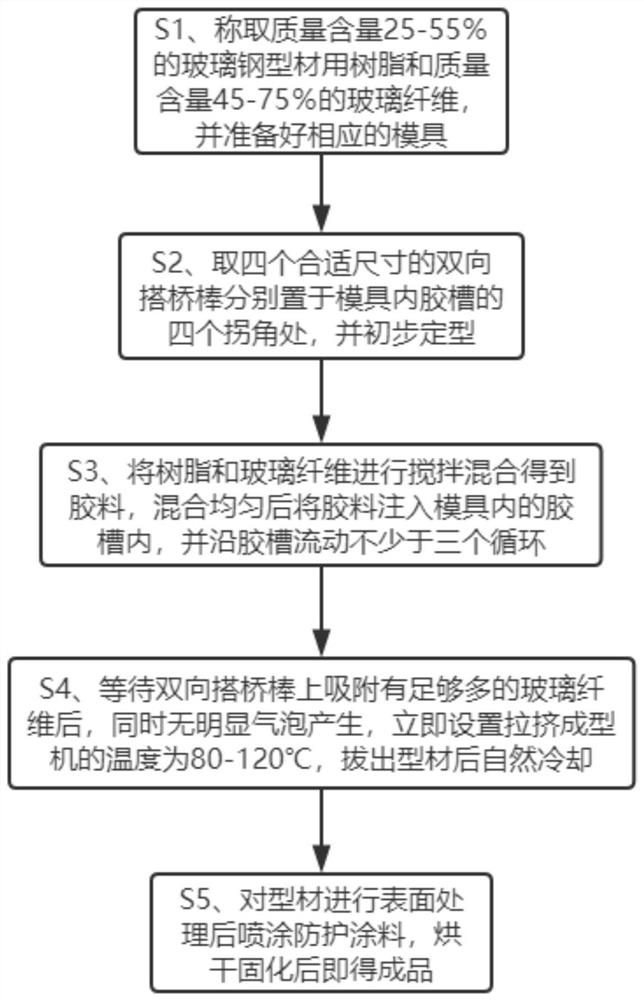

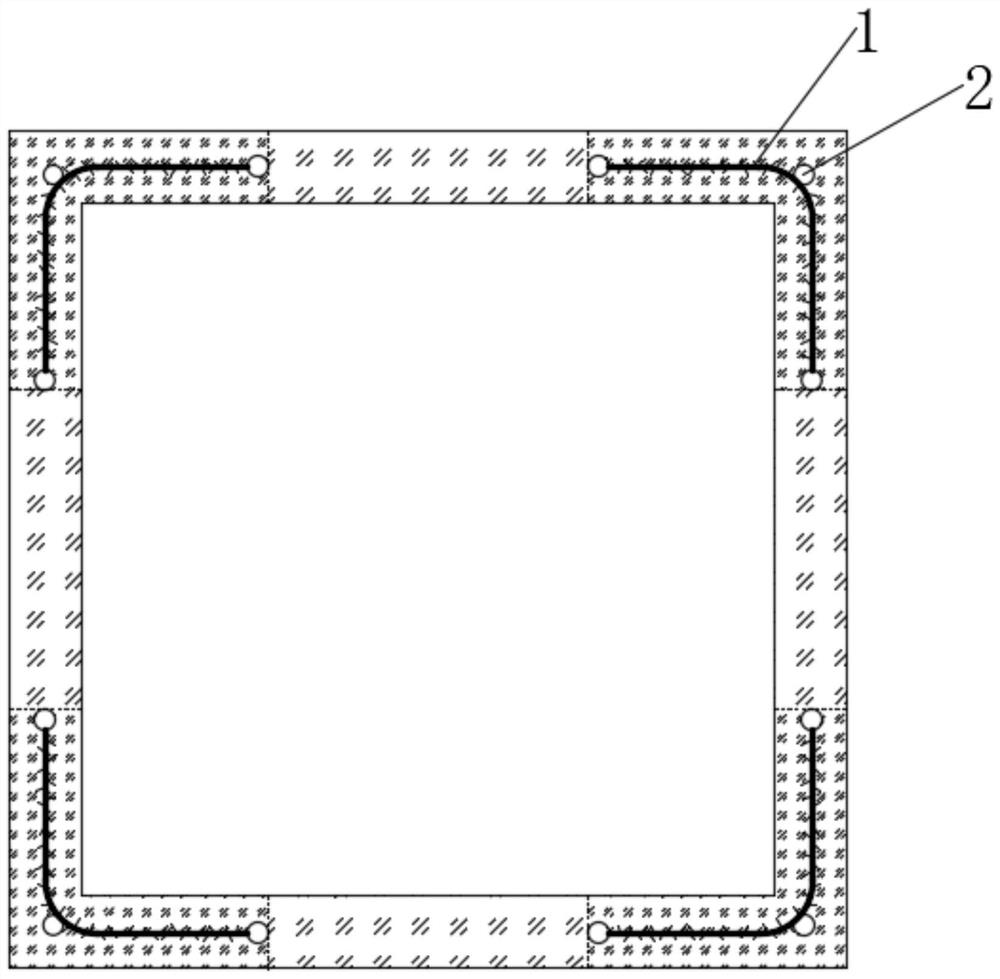

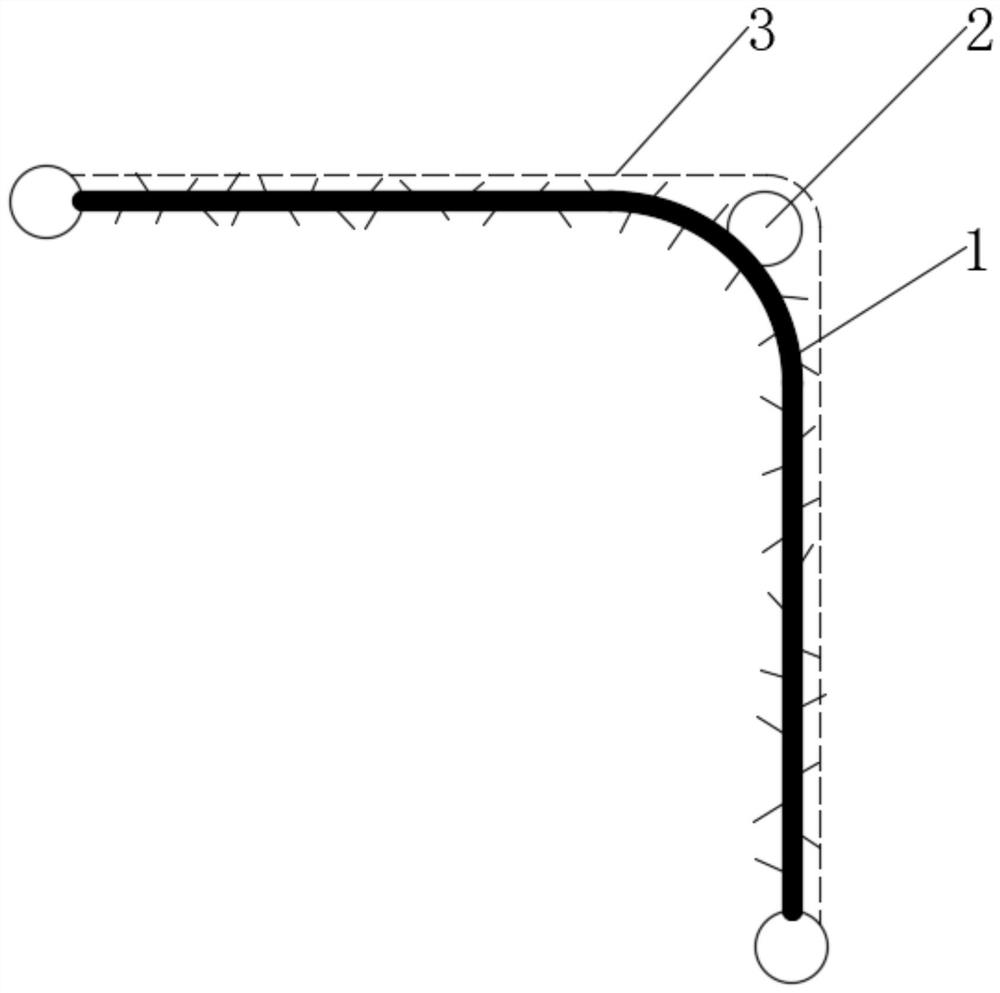

[0045] see Figure 1-2 , a method for preparing a bridging type strong corner point FRP frame, comprising the following steps:

[0046] S1. Weigh the resin for FRP profiles with a mass content of 25% and the glass fiber with a mass content of 75%, and prepare corresponding molds;

[0047] S2. Take four two-way bridging rods of appropriate size and place them at the four corners of the plastic groove in the mold respectively, and preliminarily shape them;

[0048] S3. Stir and mix the resin and glass fiber to obtain the rubber material. After mixing evenly, inject the rubber material into the glue groove in the mold, and flow along the glue groove for no less than three cycles;

[0049] S4. Wait for enough glass fibers to be adsorbed on the two-way bridging rods, and at the same time, no obvious air bubbles are generated. Immediately set the temperature of the pultrusion molding machine to 80°C, and cool naturally after pulling out the profile;

[0050] S5. After surface trea...

Embodiment 2

[0057] A method for preparing a bridging type strong corner point FRP frame, comprising the following steps:

[0058] S1. Weigh the resin for FRP profiles with a mass content of 40% and the glass fiber with a mass content of 60%, and prepare corresponding molds;

[0059] S2. Take four two-way bridging rods of appropriate size and place them at the four corners of the plastic groove in the mold respectively, and preliminarily shape them;

[0060] S3. Stir and mix the resin and glass fiber to obtain the rubber material. After mixing evenly, inject the rubber material into the glue groove in the mold, and flow along the glue groove for no less than three cycles;

[0061] S4. After waiting for enough glass fibers to be adsorbed on the two-way bridging rods and no obvious air bubbles, immediately set the temperature of the pultrusion molding machine to 100°C, and cool naturally after pulling out the profile;

[0062] S5. After surface treatment is carried out on the profiles, a pr...

Embodiment 3

[0066] A method for preparing a bridging type strong corner point FRP frame, comprising the following steps:

[0067] S1. Weigh the resin for FRP profiles with a mass content of 55% and the glass fiber with a mass content of 45%, and prepare corresponding molds;

[0068] S2. Take four two-way bridging rods of appropriate size and place them at the four corners of the plastic groove in the mold respectively, and preliminarily shape them;

[0069] S3. Stir and mix the resin and glass fiber to obtain the rubber material. After mixing evenly, inject the rubber material into the glue groove in the mold, and flow along the glue groove for no less than three cycles;

[0070] S4. After waiting for enough glass fibers to be adsorbed on the two-way bridging rods and no obvious air bubbles, immediately set the temperature of the pultrusion molding machine to 120°C, and cool naturally after pulling out the profile;

[0071]S5. After surface treatment is carried out on the profiles, a pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com