Animal fat refining device

An oil refining device and animal fat technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, and fat generation, and can solve the problems of oil residue treatment and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

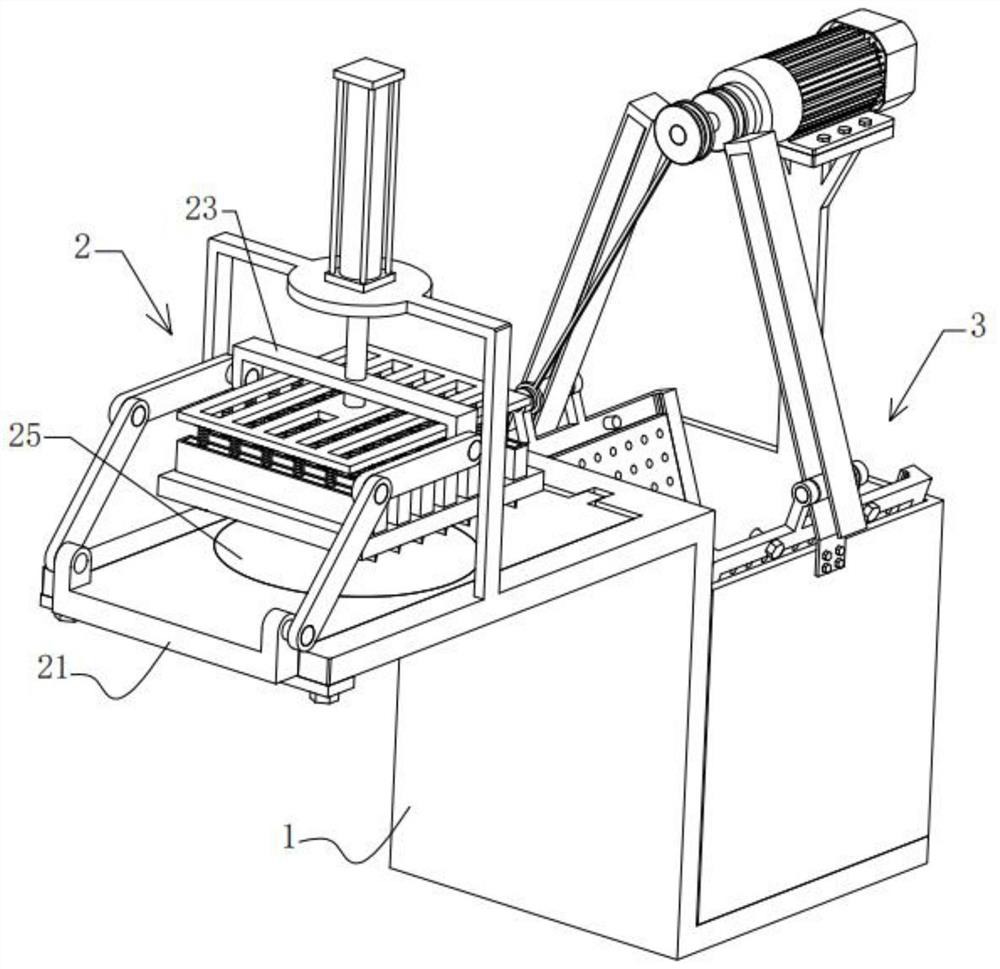

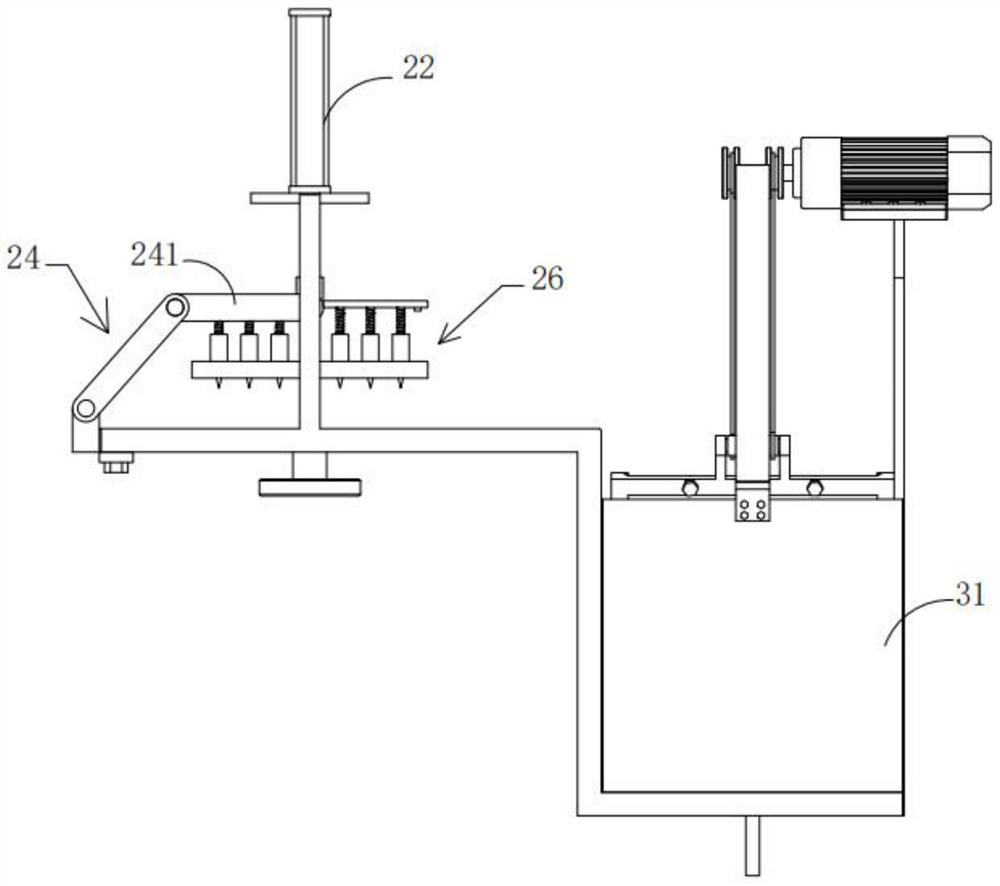

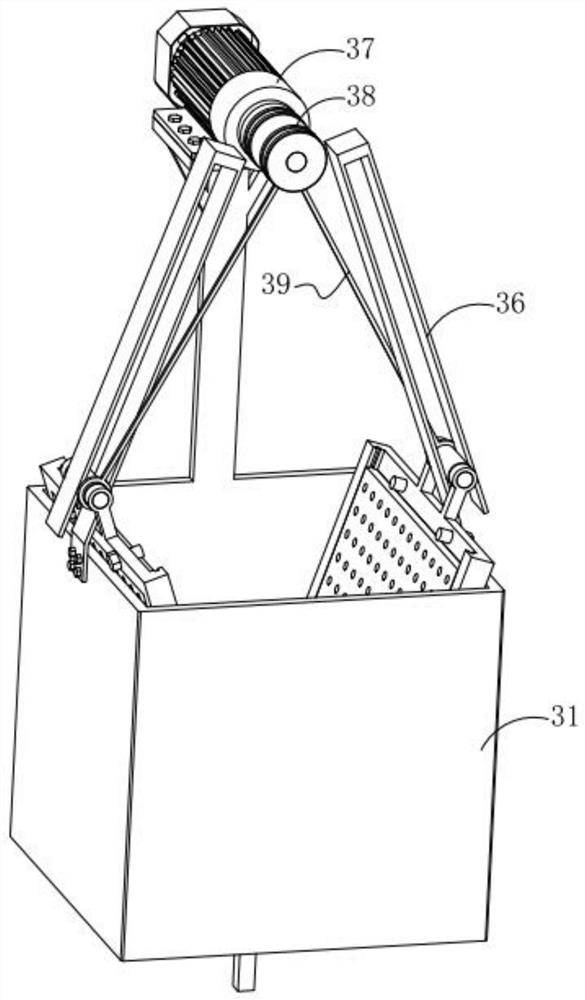

[0026] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0027] An animal fat refining device, comprising a frame 1, a fat cutting mechanism 2 and an oil refining mechanism 3, wherein:

[0028] The grease cutting mechanism 2 is arranged on the frame 1 and is used for cutting the grease block. The grease cutting mechanism 2 includes a conveying plate 21, a hydraulic cylinder 22, a connecting frame 23, a connecting arm 24, a rotating disk 25 and a cutter assembly 26. The plate 21 is hinged on the frame 1 and is located at the upper left of the refining pot 31. When the conveying plate 21 is inclined upward, the oil will fall into the refining pot 31 under the action of gravity. In order to prevent the conveying plate 21 from falling by itself under the action of gravity A limit plate in contact with the bottom of the conveying plate 21 can be set on the frame 1, a hydraulic cylinder 22 is set on the frame 1, and a connecting frame 23 and a cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com