High-temperature-resistant shielding putty with high flame retardance and high bonding strength and preparation method thereof

A high flame-retardant, high-temperature-resistant technology, applied in the field of nuclear radiation protection, can solve problems such as difficulty in ensuring the stability and safety of material structure, low bonding strength of shielding putty, difficulty in meeting the requirements of special devices or accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

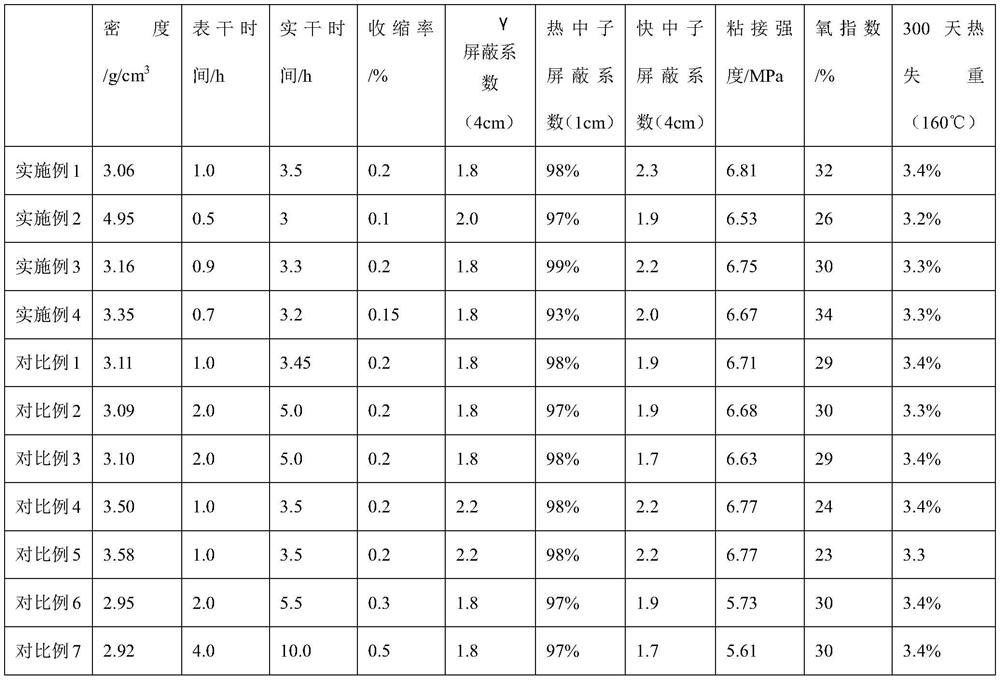

Examples

Embodiment 1

[0034] A high temperature-resistant shielding putty with high flame retardancy and high bonding strength, which is composed of the following components in weight percentage:

[0035] 16.35wt% epoxy resin, 60wt% lead powder, 5.11wt% boron carbide, 4.54wt% alicyclic amine, 14wt% aluminum hydroxide.

[0036] Concrete preparation process is as follows:

[0037] S1. Add epoxy resin and aluminum hydroxide to the vacuum mixing system in proportion, stir at a rate of 30r / min for 10min, and stir evenly;

[0038] S2. Add lead powder and boron carbide, and stir at a rate of 30r / min for 20min under vacuum conditions to stir evenly;

[0039] S3. Add aluminum hydroxide, continue stirring at a rate of 70r / min for 30 minutes, and pour according to different construction requirements or joint filling structure requirements;

[0040] The degree of vacuum in steps S1-S3 is 1-2 Pa during the stirring process.

Embodiment 2

[0042] A high temperature-resistant shielding putty with high flame retardancy and high bonding strength, which is composed of the following components in weight percentage:

[0043] Epoxy resin 7.825wt%, lead powder 80wt%, boron carbide 5.47wt%, alicyclic amine 1.815wt%, aluminum hydroxide 4.89wt%.

[0044] Concrete preparation process is as follows:

[0045] S1. Add epoxy resin and aluminum hydroxide to the vacuum mixing system in proportion, stir at a rate of 30r / min for 10min, and stir evenly;

[0046] S2. Add lead powder and boron carbide, and stir at a rate of 40r / min for 20min to stir evenly under vacuum conditions;

[0047] S3. Add aluminum hydroxide, continue to stir at a rate of 60r / min for 30 minutes, and pour according to different construction requirements or joint filling structure requirements;

[0048] The degree of vacuum in steps S1-S3 is 1-2 Pa during the stirring process.

Embodiment 3

[0050] The present embodiment is based on embodiment 1, and the difference with embodiment 1 is, by weight percentage, is made of following components:

[0051] 16wt% epoxy resin, 60wt% lead powder, 10wt% boron carbide, 4wt% alicyclic amine, 10wt% aluminum hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com