Hydrophilic UV photocuring monomer, aqueous emulsion and preparation methods of hydrophilic UV photocuring monomer and aqueous emulsion

A photocurable monomer, hydrophilic technology, applied in ether preparation, alkylene oxide preparation ether, organic chemistry, etc., can solve the problems of poor curing effect, damage of epoxy group of photocurable monomer, weak strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

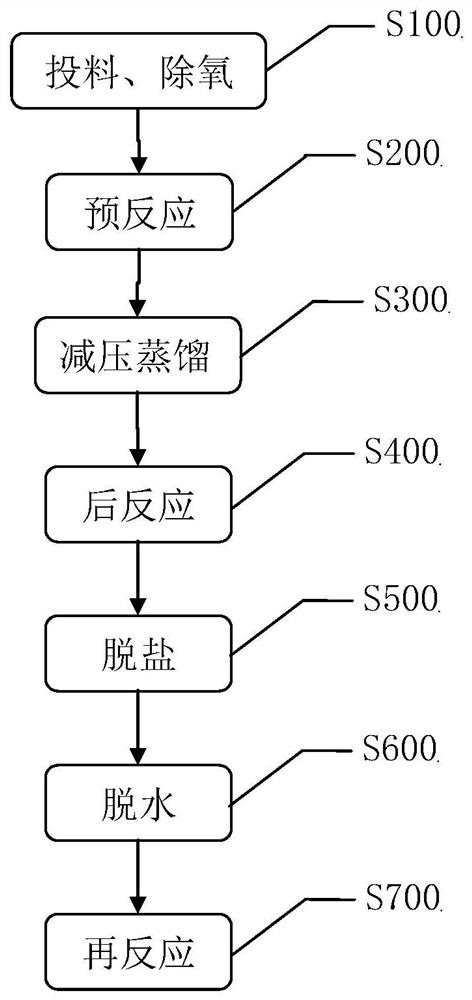

[0034] Such as figure 1 As shown, the present invention provides a kind of preparation method of above-mentioned hydrophilic UV photocurable monomer, comprises the following steps:

[0035] Step S100. Feeding and deoxygenation: Add bisphenol A polyoxyethylene ether and potassium hydroxide into the reactor, and cycle the reactor for several times to vacuumize and set nitrogen to complete deoxygenation; wherein, the reactor The number of times of carrying out cyclical vacuuming and putting nitrogen is preferably 3 times.

[0036] Step S200. Pre-reaction: under the protection of nitrogen, heat up and add epichlorohydrin to the reaction kettle for reaction. When a certain amount of epichlorohydrin is added, start stirring, and continue to add epichlorohydrin to mature Reaction; wherein, the heating temperature is 60°C to 80°C, and epichlorohydrin is added to the reactor by slow dripping, the rate of addition is 4g / min and when half of the epichlorohydrin is added slowly Turn on ...

Embodiment 1

[0051] The preparation steps of the hydrophilic UV photocurable monomer emulsion of Example 1 of the present invention are as follows:

[0052] 1. 1000g bisphenol A polyoxyethylene ether and 3g KOH are added in the reactor, and the reactor is circulated 3 times to vacuumize and put nitrogen to remove oxygen; the number of the ethoxy group of the bisphenol A polyoxyethylene ether is 2, that is, bisphenol A polyoxyethylene (2) ether.

[0053] 2. Under nitrogen protection, at 60°C, slowly drop 644g of epichlorohydrin (ECH) for pre-reaction, and continue the reaction for 3h after the dropwise addition.

[0054] 3. Distill the pre-reaction product under reduced pressure at 80° C. to remove unreacted epichlorohydrin.

[0055] 4. After the distillation under reduced pressure, 316g of NaOH was added to the reaction system at 30°C, and the reaction was stirred for 3h.

[0056] 5. Add a certain amount of distilled water, stir for 1 hour, let stand for 2 hours, and use a separatory fun...

Embodiment 2

[0062] The preparation steps of the hydrophilic UV photocurable monomer emulsion of Example 2 of the present invention are as follows:

[0063] 1. 1000g bisphenol A polyoxyethylene ether and 3g KOH are added in the reactor, and the reactor is circulated 3 times to vacuumize and put nitrogen to remove oxygen; the number of the ethoxy group of the bisphenol A polyoxyethylene ether is 2, that is, bisphenol A polyoxyethylene (2) ether.

[0064] 2. Under nitrogen protection, at 60°C, slowly drop 644g of epichlorohydrin (ECH) for pre-reaction, and continue the reaction for 4h after the dropwise addition.

[0065] 3. Distill the pre-reaction product under reduced pressure at 80° C. to remove unreacted epichlorohydrin.

[0066] 4. After vacuum distillation, 316g NaOH was added to the reaction system at 30°C, and the reaction was stirred for 4h.

[0067] 5. Add a certain amount of distilled water, stir for 1 hour, let stand for 2 hours, and use a separatory funnel to separate the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com