Electroplating wastewater chemical precipitation treatment method

A technology for electroplating wastewater and chemical precipitation, which is used in metallurgical wastewater treatment, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

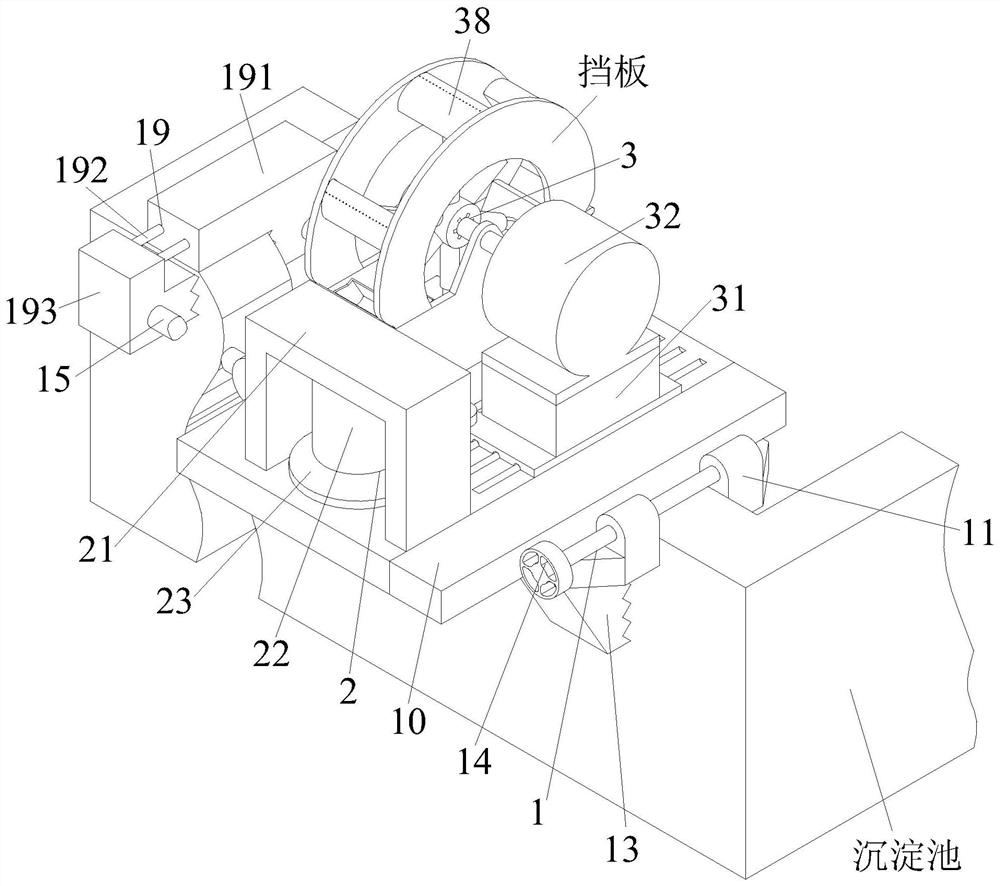

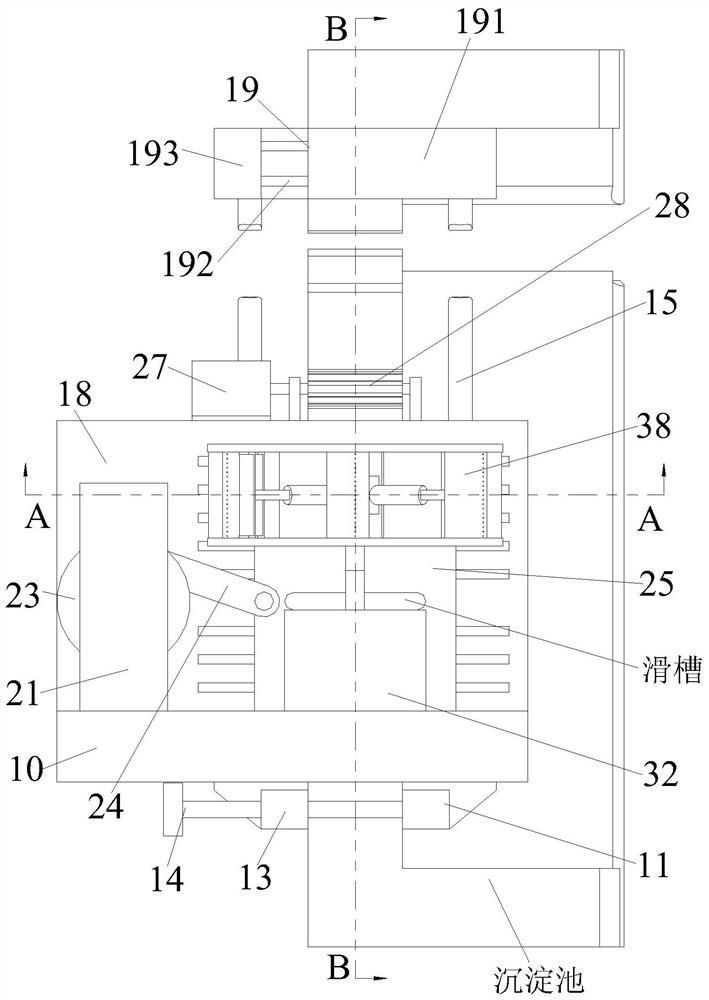

[0039] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0040] A method for chemical precipitation treatment of electroplating wastewater, which uses chemical precipitation treatment equipment for electroplating wastewater, the chemical precipitation treatment equipment for electroplating wastewater includes a fixing device 1, a shaking device 2 and a feeding device 3, and the electroplating wastewater chemical precipitation treatment equipment is used to treat electroplating wastewater When carrying out chemical precipitation, the specific method is as follows:

[0041] S1. Equipment inspection: check the electroplating wastewater chemical precipitation treatment equipment before using it to treat electroplating wastewater;

[0042] S2. Feeding treatment: After the equipment inspection is completed, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com