Carbon dioxide-methane plasma high-temperature reforming device and high-temperature reforming method

A carbon dioxide, reformer technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as shortened service life and catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

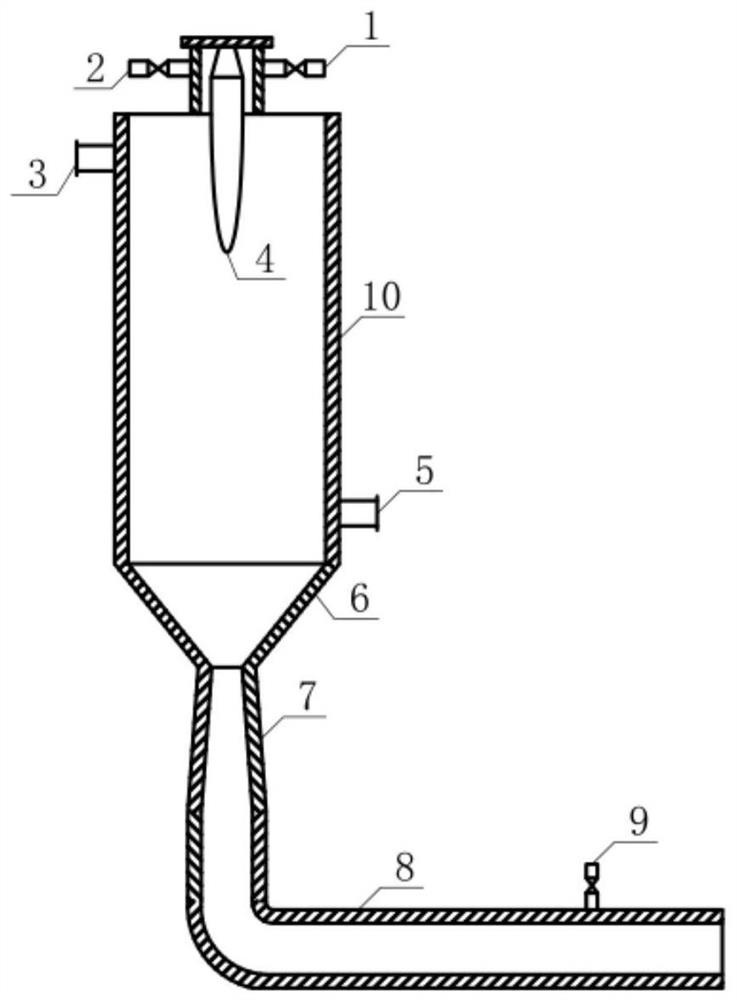

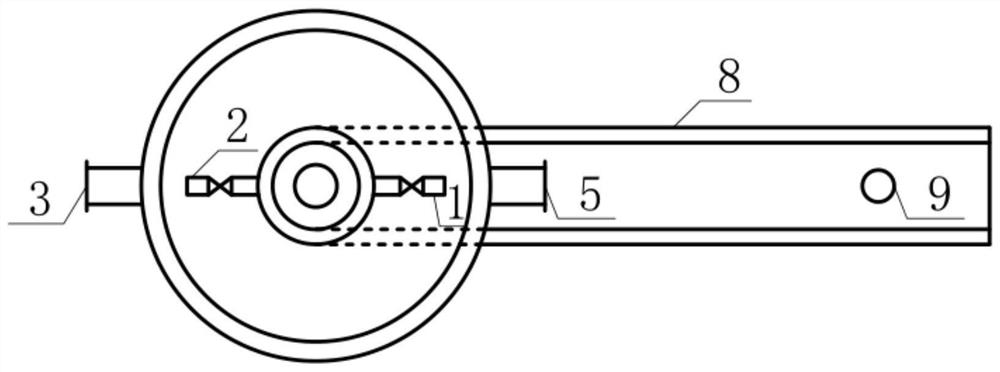

[0024] Such as figure 1 , figure 2 As shown, a carbon dioxide-methane plasma high-temperature reforming device includes a plasma jet device and a cooling water system.

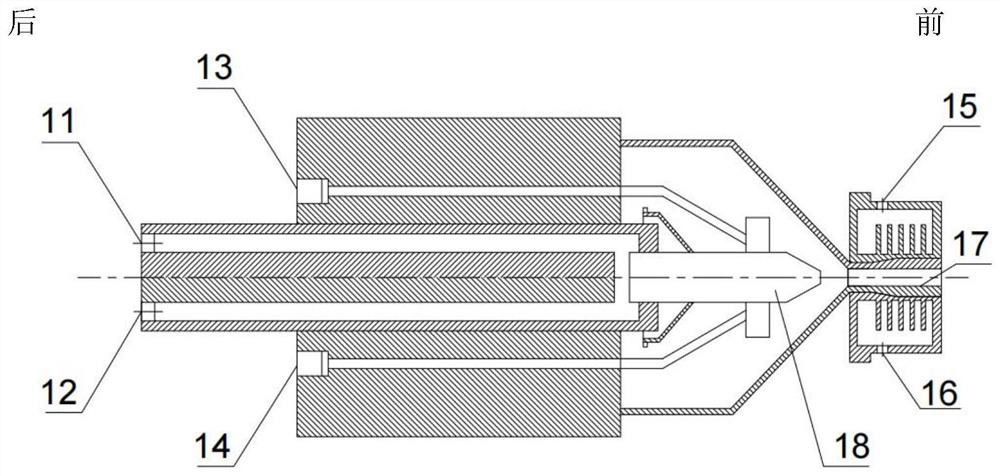

[0025] The plasma jet device 10 is configured as a coaxial hollow cylindrical metal shell with a wide top and a narrow bottom, and the transition between the diameter-changing cylinders is natural. The upper end of the plasma jet device 10 is provided with a plasma torch 4, the plasma torch 4 is located on the central axis of the plasma jet device 10, and CO 2 Inlet 1 and CH 4 air intake 2. The plasma torch 4 generates a high-temperature flame in the plasma jet device 10 , so the inner wall of the plasma jet device 10 is covered with fire-resistant and high-temperature-resistant materials. Since the flame temperature is as high as 2000-3000°C, the refractory and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com